How to unscrew a brake pipe with torn edges

Content

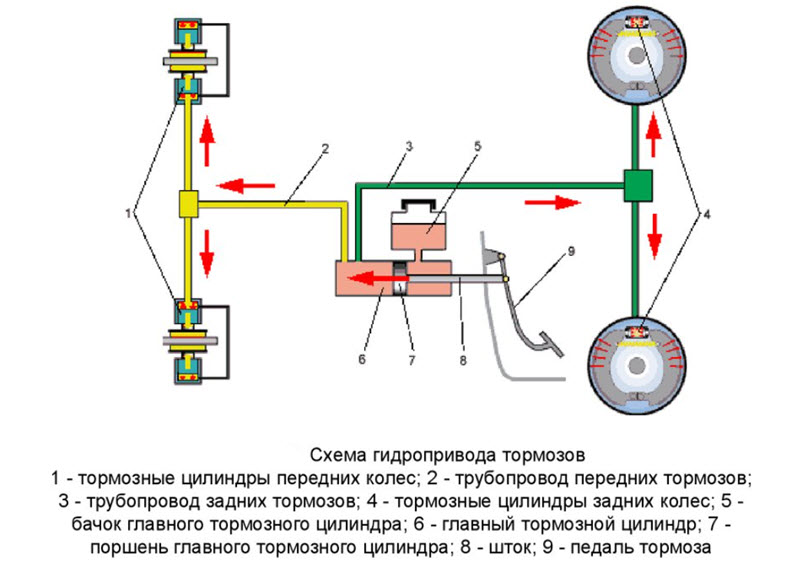

After long periods of operation and considerable mileage, in cars, it will most likely be necessary to dismantle some of the parts of the brake system, which is associated with unscrewing the captive tubular nuts at the ends of the brake pipes. Over time, this becomes difficult due to the souring of the thread. If the tube is to be replaced and there is no need to save it, the mating part can be expensive and in working condition. We have to look for a way to safely unscrew the tube fasteners.

What Causes Brake Pipes to Die?

In the initial state, the nut has an anti-corrosion coating, but the tightening torque is such that its integrity is violated and direct metal-to-metal contact is formed. In order to reduce the cost of construction, both mating parts are made of iron alloys, which are easily corroded when in contact with oxygen and moisture.

In addition to the external influence of substances aggressive to iron, internal factors can also play a role. This is the ingress of decomposition products of brake fluid components and galvanic effects due to the combination of different metals in one contact.

The result is always the same - corrosion products accumulate between the threads, which have a significant volume and burst the thread with great effort. It becomes impossible to unscrew it by conventional methods.

In addition to the souring of the thread, the brake pipe also sticks to the union nut. If the tube is to be replaced, then this does not play any role, but when trying to save the native part, difficulties begin. Even with the nut starting to rotate, scrolling the tube with it does not allow even one full turn.

How to properly dismantle

The task is divided into two parts - to preserve, if possible, the edges of the nut and not allow it to be cut off, leaving a fragment in the body of the counterpart.

If integer faces

As long as the edges of the nut are not damaged, use the correct unscrewing tool. The use of a ring or, even more so, an open-end wrench is inappropriate here.

For brake pipes, special ring spanners are produced, having a considerable width, equipped with a slot for the tube and a clamp with a power screw. The key is put on the nut with the passage of the tube into the slot and securely fixed with a threaded clamp. Breaking the edges in this case will no longer work.

There remains the danger of shearing the nut by excessively applied torque. The part is thin-walled and weak, it is damaged with a very moderate effort on a short key lever, so the soured connection should be loosened as much as possible.

There are several ways that you need to apply everything in sequence to eliminate trouble:

- the connection must be shed with a penetrating compound such as a “liquid key”, usually a universal lubricant such as WD40 or the like is sufficient, it will take about half an hour to obtain the effect of wetting the threads;

- the nut must be carefully tapped in the lateral and axial directions, along the axis it is convenient to do this through the same special key, but of a smaller size, put on the tube and placed against the nut, the blows are applied with a small hammer close to the key head, sharply and abruptly;

- from the side, you should beat through a blunt beard along the edges of the nut with the same hammer, it’s not strength that matters, but sharpness and repeated repetition, between attempts you need to try the nut to unscrew without applying too much force, skill and a sense of proportion play a big role;

- An extreme but effective measure will be repeated heating of the part with a gas burner with a thin pinpoint nozzle, when heated and cooled, the bursting porous products will be crushed, you should not turn the hot nut, because it is expanded and clamped even more, you can cool it with the same penetrating liquid.

Of course, when working with heat, the brake fluid must be completely drained and fire safety measures taken.

If the edges are broken

It happens that illiterate attempts to turn away have already led to damage to the edges. At a certain stage, this will not prevent you from reliably hooking on with the same special key, it will tightly cover and clamp everything that is still left.

Alternatively, you can cut the tube and use a reduced size socket with a grip on the middle of the faces. But the special key is still more effective.

Sometimes a welding machine is used for dismantling, welding another, larger diameter, to the protruding part of the nut. The main effect with this method is precisely the extreme heating of the part, after which it surprisingly easily turns away from a small effort.

The last option would be to drill out the remnants of the nut and remove the threads. Work carefully so as not to damage the mating part.

Watch this video on YouTube

Even if the tube could be dismantled, it would be better to replace it. After dealing with a soured thread, the connection will lose such properties as strength, reliability and tightness. You can use standard parts or make a new copper tube yourself by applying repair technologies for expanding it from the side of contact with the caliper or hose.

Copper corrodes much less, which will provide increased safety in the operation of the brake system. Factories do not use it out of economy in mass production.

What to do so that in the future the brake pipes do not turn sour

There is no universal recipe here, it all depends on the time. But the use of penetrating anti-corrosion compounds for body cavities, which envelop the parts, prevent the development of corrosion due to the inhibitors present in the composition, and do not allow water and oxygen to pass to the thread, helps well.

The connection of the tube, nut and counterpart is abundantly wetted with one of these compounds. After drying, they remain in a fairly elastic state.

On top of this treatment, a layer of protection with more durable characteristics can be applied. These can be compounds such as anti-gravity or other body sealants. If necessary, they are easily removed.

The thread itself is coated with a special lubricant containing finely dispersed copper before wrapping. Such auto chemicals have recently been widely used in repair installation, greatly facilitating subsequent unscrewing.