How to adjust valve clearances in an engine

Content

During engine operation, all parts change their geometric dimensions due to thermal expansion, which is not always exactly predictable. This problem also concerns the drive of the valves of the gas distribution mechanism in four-stroke engines. Here it is important to open and close the inlet and outlet channels very accurately and in a timely manner, acting on the end of the valve stem, which is difficult in conditions of expansion, both of the stems themselves and of the entire block head.

Designers are forced to leave thermal gaps in the joints or resort to installing their mechanical compensation units.

The role of valves and valve timing in the engine

One of the most important characteristics of an engine when it comes to its maximum power output with acceptable fuel consumption is filling the cylinders with fresh mixture. It enters the working volume through the valve system, they also release exhaust gases.

When the engine is running at significant speeds, and they can be considered, with some assumption, both maximum and minimum idling, the masses of gas passing through the cylinders begin to show their aerodynamic properties, inert and others associated with the efficiency of combustion and thermal expansion.

The accuracy and optimality of fuel energy extraction and its transformation into mechanical energy depend on the timely supply of the mixture to the working area, followed by its no less prompt removal.

The moments of opening and closing of the valves are determined by the phase of the piston movement. Hence the concept of phased gas distribution.

At any time, and for the motor this means the angle of rotation of the crankshaft and the specific stroke of the engine within the cycle, the state of the valve is determined quite clearly. It can depend only on the speed and load within strictly normalized limits set by the phase adjustment system (phase regulators). They are equipped with the most modern and advanced engines.

Signs and consequences of incorrect clearance

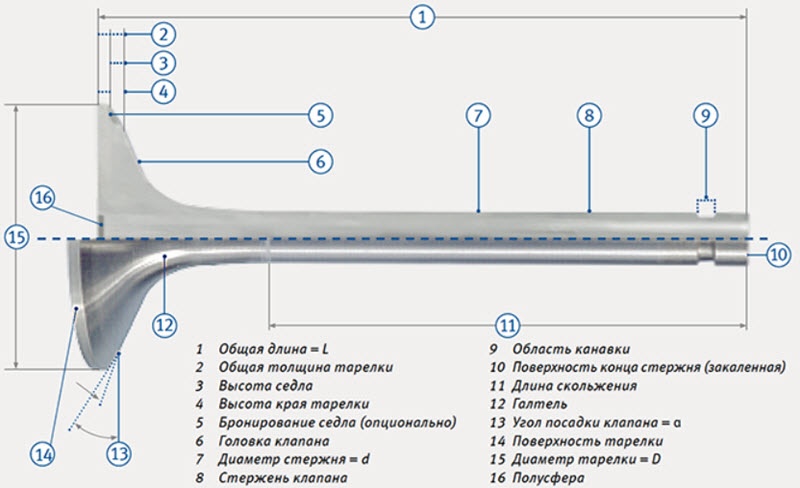

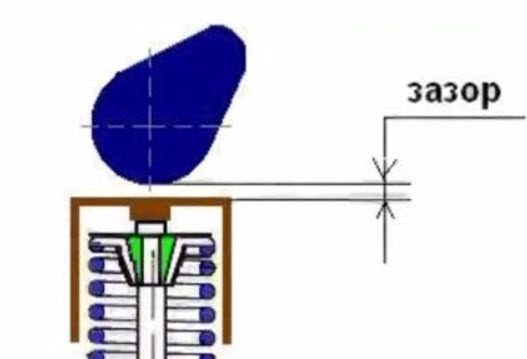

Ideally, the accuracy of the valves ensures zero backlash. Then the valve will clearly follow the trajectory set by the profile of the camshaft cam. It has a rather complex and carefully selected form by the developers of the motor.

But this can only be realized when using hydraulic gap compensators, which, depending on the specific design, are also called hydraulic pushers and hydraulic supports.

In other cases, the gap will be small, but quite finite, depending on temperature. The developers of the internal combustion engine, experimentally and by calculation, determine what it should be like initially, so that under any conditions a change in clearances does not affect the operation of the motor, causing damage to it or lowering its consumer qualities.

Large clearance

At first glance, increasing valve clearances looks safe. No thermal changes will reduce them to zero, which is fraught with problems.

But the growth of such reserves does not pass without a trace:

- the engine starts to make a characteristic knock, which is associated with increased acceleration of parts before coming into contact;

- shock loads lead to increased wear and chipping of metal surfaces, the resulting dust and chips diverge throughout the engine, damaging all parts that are lubricated from a common crankcase;

- valve timing begins to lag due to the time required to select the gaps, which leads to poor performance at high speeds.

Interestingly, a loud knocking engine with huge gaps can pull perfectly at low revs, gaining, as they say, “tractor traction”. But you can’t do this intentionally, the motor will be quickly worn out by products from surfaces that experience shock loads.

small gap

Reducing the gap is fraught with much faster and irreparable consequences. As it warms up, insufficient clearance will quickly become zero, and an interference will appear in the joint of the cams and valves. As a result, the valve plates will no longer fit tightly into their sockets.

The cooling of the valve discs will be disturbed, they, according to calculation, discharge part of the heat into the metal of the head during the closing phase. Although the valves are made from high temperature steels, they will quickly overheat and burn out using the heat and available oxygen. The motor will lose compression and fail.

Valve clearance adjustment

Some engines tend to increase valve clearances during normal operation as a result of wear. This is a safe phenomenon, since it is difficult not to notice the knock that has begun.

Much worse, and unfortunately this is how most motors behave when the gaps decrease over time. Therefore, in order to exclude zeroing of gaps and burnouts of the plates, it is necessary to carry out adjustments strictly according to the factory regulations.

We use the probe

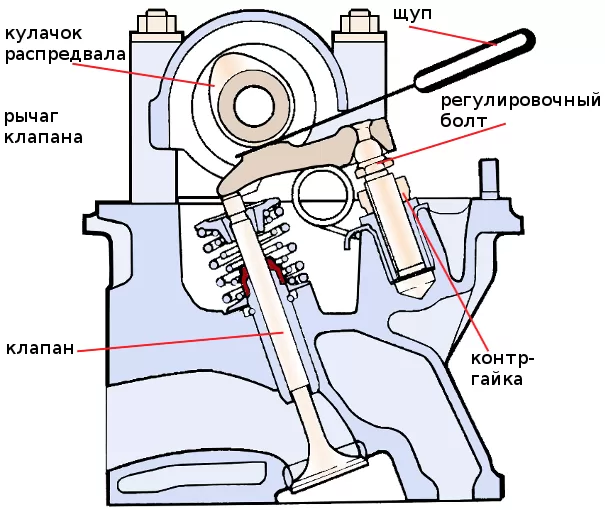

The easiest way is to remove the valve cover, move the cam away from the valve being checked and try to insert a flat feeler gauge from the kit into the gap.

Typically, the thickness of the probes has a pitch of 0,05 mm, which is sufficient for measurements with acceptable accuracy. The thickness of the maximum of the probes, which still passes into the gap, is taken as the gap size.

With rail and indicator

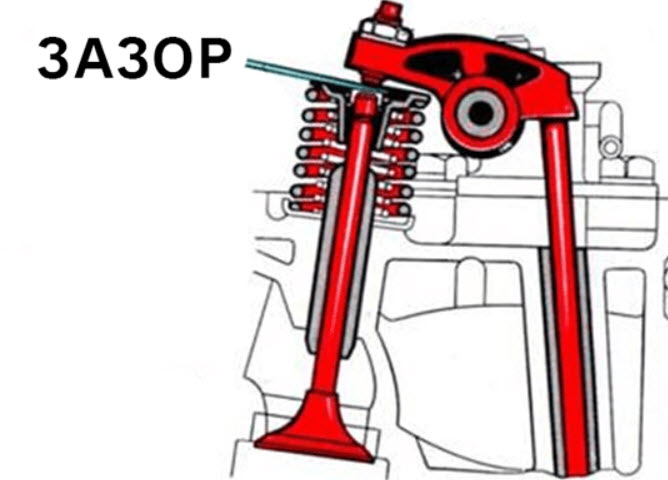

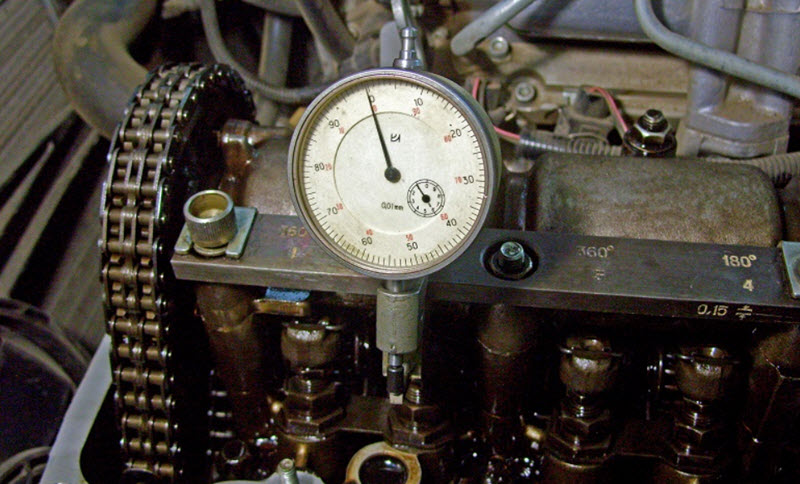

On some motors, usually those with rocker arms (levers, rockers) in the drive mechanism, it is possible to install a device in the form of a rail, on which sockets are provided for mounting an accurate dial indicator.

By bringing its leg to the lever opposite the stem, you can shake the rocker free from the cam manually or with a special fork, reading the readings on the indicator scale with an accuracy of about 0,01 mm. Such accuracy is not always needed, but it becomes much more convenient to regulate.

What to do if HBO costs

The propane-butane blend has a much higher octane rating than conventional general purpose gasoline. Accordingly, it burns more slowly, warming up the exhaust valves during exhaust. The gaps begin to decrease much more than the developers of the motor envisaged, assuming the use of gasoline.

To avoid premature burnout of plates and sockets, the gaps during adjustments are set increased. The specific value depends on the engine, usually the additive is 0,15-0,2 mm.

More is possible, but then you have to put up with noise, power reduction and increased wear on the gas distribution mechanism when working with partial loads. The best solution would be to use engines with hydraulic compensators for gas.

An example of adjusting valves on a VAZ 2107

The VAZ-2107 has a classic engine with a valve drive through rockers from a single camshaft. The gaps increase over time, the design is not perfect, so adjustment is required approximately every 20 thousand kilometers.

You can perform this operation yourself, the skill is developed quite quickly. Of the consumables, you only need a valve cover gasket, you should not try to reapply it or with a sealant, the cover is weak, the fasteners are unreliable, the motor will quickly become overgrown with dirt from leaking oil.

For work, it is highly desirable to purchase a set of rails and an indicator. The benefits are known to those who work with engines professionally and are able to appreciate the difference between a precision fixture and a conventional feeler gauge.

The order of work on the cylinders and camshaft cams is engraved on the rail itself, and is also available in any VAZ manual or repair book.

- The fourth cylinder is set to the top dead center of the compression stroke, after which valves 6 and 8 are adjusted. The gap is measured with an indicator, after which the lock nut is loosened and the calculated wear compensation is introduced with an adjusting bolt.

- Further, the operations are repeated for all valves, turning the crankshaft sequentially by 180 degrees, or it will be 90 along the camshaft. Cam numbers and angles of rotation are indicated on the rack.

- If a feeler gauge is used, it is inserted into the gap, pressed with an adjusting bolt and lock nut. They achieve such a pressure that it is pulled out of the gap with little effort, this will correspond to the standard gap of 0,15 mm.

Using the fact that the cover is removed, it will be practical to check the chain tension and the condition of the tensioner, its shoe and guide. If you need to repair something or tighten the chain, then adjust the valves after completing all the procedures with the chain.