How to fix a broken wire without soldering

Content

In this short and simple guide, we will show you how to fix a broken wire without soldering.

It is a perfect solution for those who do not know how to solder or do not have time to do it.

All you need is a few simple tools and some duct tape!

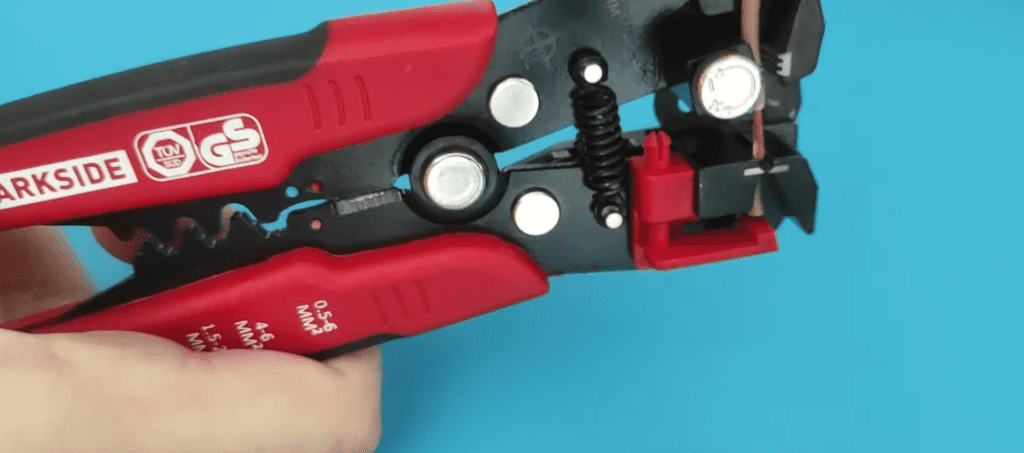

How to remove the insulation?

Stripping wire insulation is a quick and easy process that can be done with a stripping tool.

To remove the insulation from the wire, first cut off the excess insulation with sharp pliers. Then press the stripping tool against the wire and twist it to strip the insulation.

After you have removed the insulation and copper from the wire, you can begin to repair the broken wire.

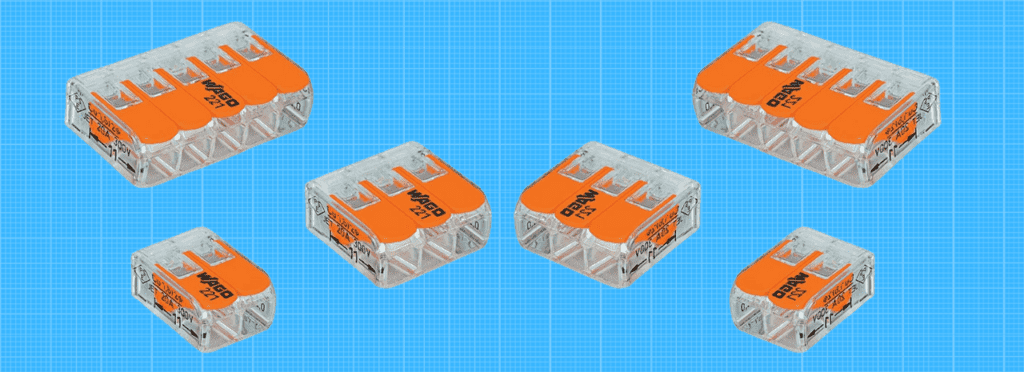

Wago connector method - strength: high

Wago connectors are a type of electrical connector that allows you to quickly connect wires. They are available in both wire-to-wire and wire-to-board configurations and can be used for both DC and AC circuits.

To connect a wire to a Wago connector, first remove the insulation from the end of the wire. Then insert the wire into the connector and tighten the screw to secure it in place. Finally, close the lever on the connector to complete the connection.

Repeat the procedure with the other side (wire).

With an easy-to-use design, they are ideal for applications that require quick and easy connection.

It literally takes you ten seconds to connect the wires.

The strength of the connection between the wires is the same as if you were soldering.

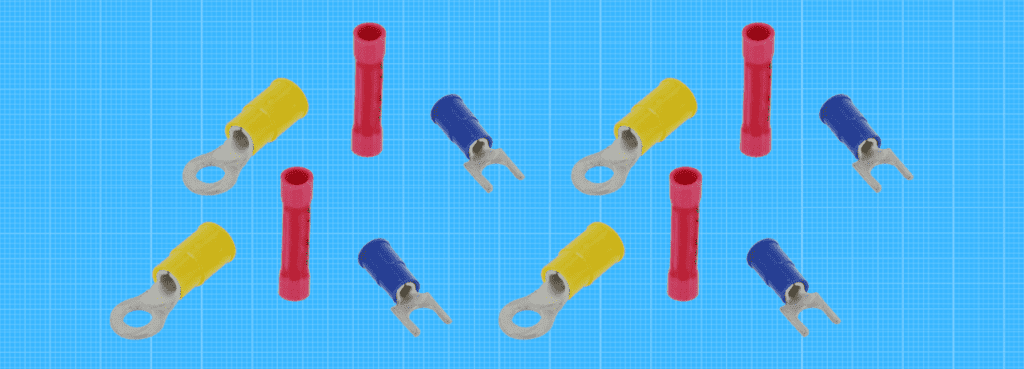

Crimp connector method – Strength: high

Crimp connectors are a quick and easy way to join wires without soldering. To use a crimp connector, remove the insulation from the wire, insert the wire into the connector, and clamp it with pliers.

Crimp connectors can be used for a wide variety of applications including automotive wiring, electrical wiring, and telecommunications wiring. They are available in a variety of sizes, colors and shapes so you can find the perfect connector for your needs.

When using crimp connectors, be sure to use the correct wire size. If a connector is too small for the size of the wire, it will not make a good connection and could potentially cause a fire.

Crimp connectors are a good replacement for connecting wires without soldering. Try it!

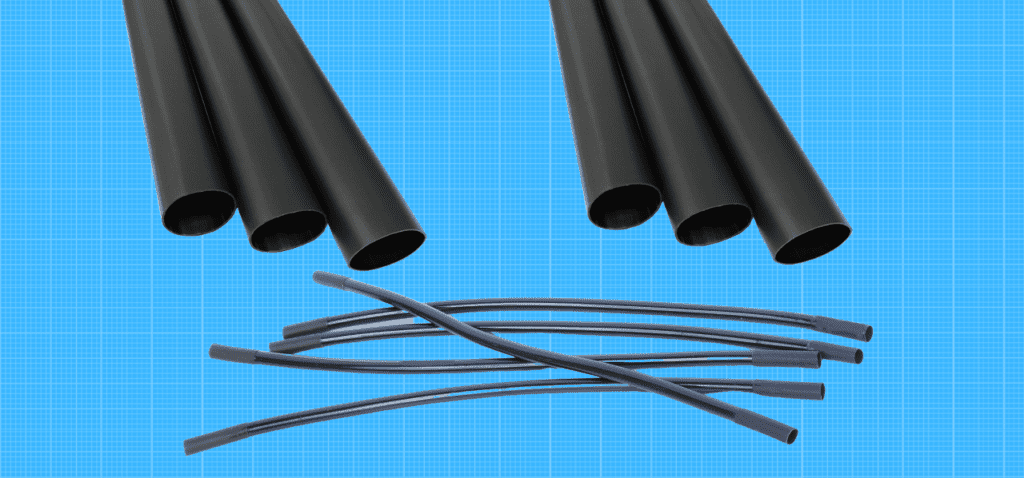

Heat Shrink Tube Method - Strength: Medium

When connecting wire with heat shrink tubing, it's important to make sure the tubing is the correct size. The tube should be large enough to fit over the wire, and tight enough not to slip off.

Once you have chosen the right tube, you will need to cut it to the correct length. Be sure to leave enough extra so that you have something to work with.

Twist the wires. Then stretch the heat shrink tubing.

Now it's time to start shrinking the tube. This can be done with a heat gun or with a flame from a lighter. When using a heat gun, keep it at least six inches away from the pipe. If you get too close, you risk melting the tube. Slowly move the gun through the pipe, making sure all areas heat up evenly.

If you are using a lighter, keep the flame about an inch away from the tube. Again, be sure to move it so that all areas are evenly heated.

Once the tube shrinks, let it cool for a few seconds before moving on.

If you need to, you can now cut off the excess tube with a sharp knife.

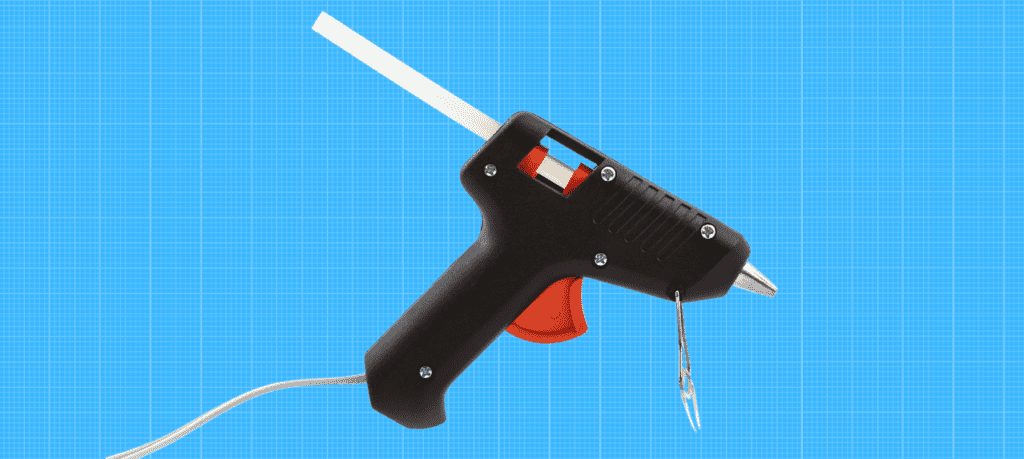

Hot glue method - strength: medium

When it comes to wiring, one of the most popular ways to connect components is to use hot glue. This is because hot glue is easy to use, and you probably already have it at home. It does not require any special tools or equipment.

To use hot glue for wiring, start by heating the glue gun. When the glue has melted, hold the wire with one hand and apply the glue to the wire with the other. Wrap the wire around the component you're connecting it to and hold it in place until the glue dries.

Now that you know how to use hot glue for wiring, you can start connecting components in your projects. It's a quick way to get the job done, and a lot less messy than using solder.

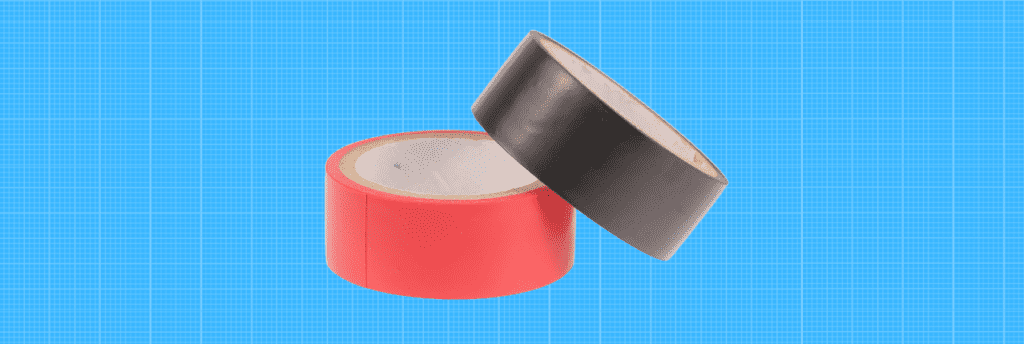

Tape Method - Strength: Medium

Wires can be easily connected with electrical tape. Simply wrap the wire with tape a few times, then twist the bare metal ends of the wire around each other to create a secure connection.

This is the cheapest option, but not the best. If you are looking for a more reliable solution, consider using solder. Solder creates a much stronger bond and will last longer than duct tape.

Video Tutorial

In the video, we show how to join wire without soldering using these methods.

What can be used instead of solder?

Some homemade alternatives to soldering wire connections:

hot glue gun: This is a popular choice for many people because it is easy to use and readily available. The downside is that it is not very strong and can melt easily if it gets too hot.

superglue: This is another popular choice as it is easy to use and dries quickly. However, it is not very durable and can break easily.

tape: This is a good choice for temporary connections as it is easy to use and remove. But it is not very durable and can loosen over time.

Insulating tape: This is the best choice for temporary connections as it is more durable than regular tape. But it can be a little tricky to use and can be hard to remove.

Wire Connectors: This is a good choice for permanent connections as they are very durable and easy to use. But they can be a little pricey depending on the type you choose.

Crimp connectors: This is another good choice for permanent connections because they are very durable and easy to use. But they can be a little pricey depending on the type you choose.

How safe is it to fix a broken wire without soldering?

There is a risk of electric shock when you repair a broken wire, whether you soldered it on or not. If you're not comfortable with the risks involved, it's best to call a professional.

How to check if the wire is correct?

To test wire connections with a multimeter, first locate the two wires you want to test. Touch the black test lead to one wire and the red test lead to the other wire.

If the multimeter reads 0 ohms, then the connection is good. If the multimeter reading is not 0 ohms, then there is a bad connection and needs to be corrected.