How to Attach Wires to a PCB Without Soldering

Content

By the end of this article, you will be able to securely connect wires to a PCB without soldering them.

Sometimes you will not be comfortable with soldering or you will not have tools on hand and you will need a way to do it in a pinch. There are several effective replacement methods you can use to attach wires to circuit boards - using terminal blocks, connectors, quick-fix adhesive, applying liquid rosin, and more. Also, soldering the wires reduces the flexibility of the wires, making this method misleading.

There are several steps you can take to connect wires to any PCB without soldering.

- First, unplug the device and clean it with a cleaning agent.

- Remove any twitchy wires and secure the wires on each side with quick fix adhesive or contact adhesive.

- Alternatively, you can use the Wire to PCB method, which uses a single point of contact to attach a wire to a board.

- Applying liquid rosin is also a workable method: heat the liquid rosin and let it drip onto the copper wire and solder while it cools.

We'll go into more detail below.

How to Attach Wires to a PCB Without Solder

In the process of building a circuit, you cannot always solder all the wires together. In this case, quick-release adhesives come to the rescue, which can be used to secure cables.

Small items such as resistors can be easily connected with fast fix adhesive. In this situation, you will attach the wire to the connector bar and turn the board over.

Since most electrical connections in computers and related electronics are wired, you might think that soldering is the only option when it's not.

This guide will show you everything you need to do to join PCB pieces with glue.

When connecting wires to a PCB, you have three options:

Option 1

Here you attach the wire to the PCB without any reinforcement. This is the most inexpensive technique.

Option 2

You can use connectors and terminal blocks to connect wires to a PCB. Unlike option 1, this method can get expensive.

Option 3

Tension wires are used to connect wires to the printed circuit board. They have incredible flexibility (97 percent) which makes them suitable. (1)

However, if solder is used to connect the wires to the PCB, they (the wires) will lose their flexibility. The wires will eventually develop a transition point that will cause them to fail.

Note that you can use a screwdriver to tighten loose wire connections.

How to connect wires to a printed circuit board with glue

The easiest way to attach wires to a PCB is to twist them together. Alternatively, you can use connectors, but the latter will cost money. Using glue is one of the most inexpensive ways to connect wires to a PCB.

So, you simply thread the wires through the board, or use glue and/or contact glue to secure the wires to the PCB itself.

Note. If you choose contact adhesive or glue, you will need more space.

The following steps will help you:

Step 1: Turn off or unplug your device

Step 2 Remove wires

Remove the wires that come loose when the battery is inserted into the circuit board.

Step 3. Hold the wires in place

Keep the wires in place and contact glue and glue are alternative options.

Connecting wires without soldering or splicing

You can build without solder and soldering iron costs using the following method:

This method allows you to use one contact point to connect the wire to the PCB. And this is the cheapest, unlike terminal blocks and connectors, which are expensive and require additional space.

Always cover wires with insulating plastic to protect them from heat and contact with other fragile items.

Step 1. Determine the size of the wires

Find a hole with the correct size for all the wires.

Step 2: Strip the Wires

Remove the insulation from one end of the two wires with a wire stripper.

Step 3. Inserting wires

Insert the stripped end of one wire into the crimp to the insulated part. Do the same for the other wire.

Step 4. Crimp the wire

Insert the crimp into the notch of the crimping tool and squeeze until the crimp is bent.

Can glue be used instead of solder?

Yes, you can use fast adhesive to connect wires of 97 or less to PCBs.

Steps:

- Twist the wires in one direction

- Attach them to a point on the PCB

- Then apply hot glue to the connected wires.

- Let it cool down.

Attention:

Open a small hole between the pad and the cable/wire leads when soldering the LEDs. Then pour the melted solder into the crack and let it drip for about two seconds.

Avoid soldering other pads on the PCB to protect the LED.

Heat shrink tubing can be used instead of glue. The method combines wires without the use of solder. The mechanism is simple: the shrink sleeve shrinks to form a solder solution. The method takes a few minutes and is very cheap. But make sure you have a stable heat source. (2)

Replacing solders with electrical tapes

As mentioned above, there are other, more convenient ways to connect wires to printed circuit boards, in addition to using solder. Wires can be attached to printed circuit boards via terminal blocks and connectors. But it will depend on the type of connection.

Another option is to attach the wires to the circuit boards with glue, but then the connection will not be properly insulated. Wires may short out.

When using solder to connect wires to a PCB, make sure it simulates a volcano or cone. The solder should be smooth and should not ball or flow onto adjacent leads and connections.

Use a clamping device to secure the wires to the printed circuit boards. You can also remove the insulation to achieve the same.

What to use instead of a soldering iron?

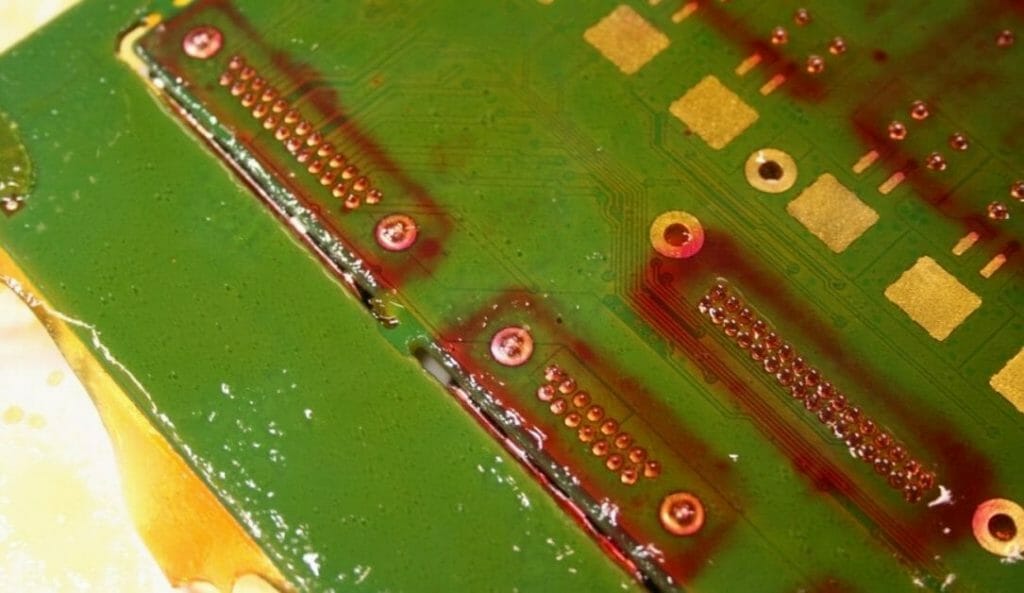

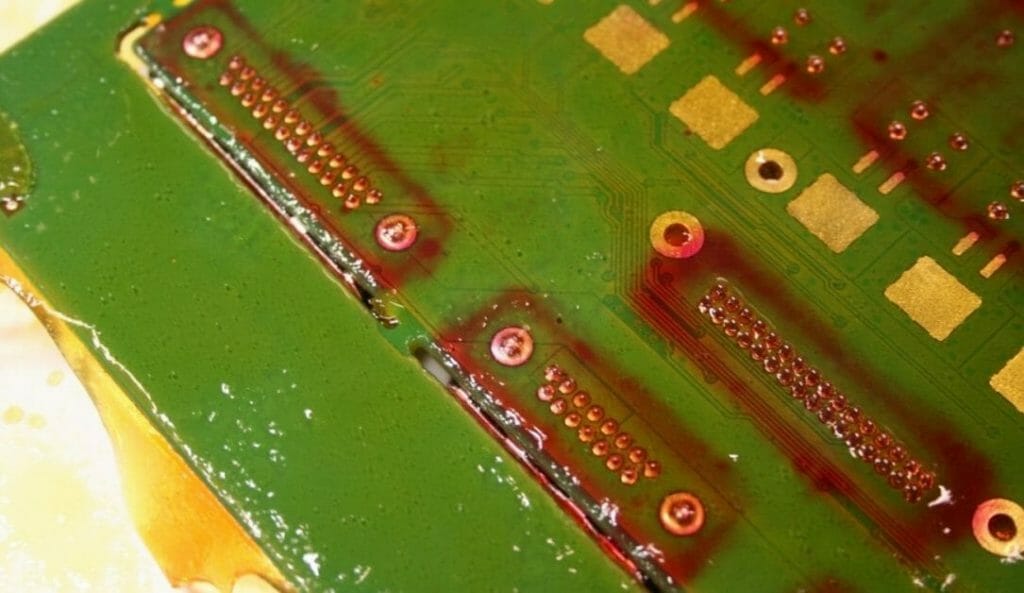

Neatness is essential in PCB connections. So, clean up wires, leads, and other PCB elements before attaching any wires. New circuit boards are clean, while old ones have traces of dirt and contaminants that can interfere with their work.

I recommend using chemical cleaners to get rid of PCB debris. And don't forget to clean and dry your soldering iron tip. A small amount of solder on the tip will conduct heat to the PCB.

Make sure the connections are strong whenever you solder a wire to the board so the solder doesn't break when you tug. Then be careful of weak spots on your PCB and repair them immediately before assembling other components.

Use flux instead of a soldering iron. The flux allows the solder to flow evenly and smoothly.

Tinning is a very important step that should not be skipped when soldering. It does the following:

- Tinning prevents solder from getting on the PCB

- Improves heat transfer

- Protects soldering tip

- Slows down wear of PCB elements.

Attention: do not use a soldering iron without tinning - the tip is fragile.

Take a look at some of our articles below.

- How to disconnect a wire from a plug-in connector

- How to cut an electrical wire

- Where to find thick copper wire for scrap

Recommendations

(1) Flexibility - https://www.healthline.com/health/benefits-of-flexibility

(2) heat source - https://www.sciencedirect.com/topics/physics-and-astronomy/heat-sources

Video link