How to solder an end fitting?

Content

- Things you will need:

- Step 1 - Clear

- Step 2 - Apply Flux

- Step 3 - Connect the Pipes Together

- Step 4 - Turn on the power

- Step 5 - Up to temperature

- Step 6 - Place the Heads on the Pipe

- Step 7 - Apply Heat

- Step 8 - Maintain Close Contact

- Step 9 - Hold for 10 seconds

- Step 10 - Test Heat

- Step 11 - Feeding the Solder

- Step 12 - Make a Neat Connection

- Step 13 - Place on a Stand

- Step 14 - Let cool

- Step 15 - Rinse and Check

Things you will need: | ||||

| plumbing iron | ||||

| Lead-free solder | |||

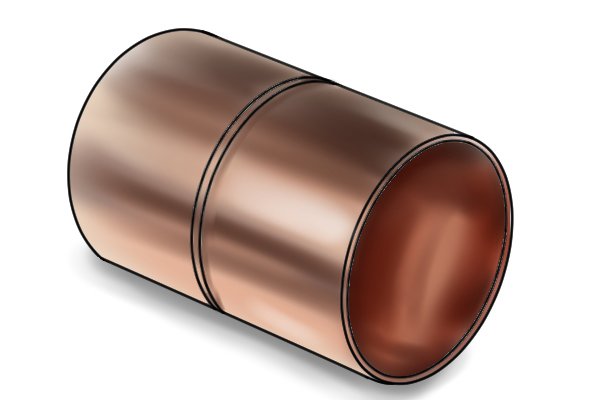

| End Feed Fittings | |||

| Copper pipe cleaning cloth or wire wool | |||

| Flow | |||

| Flux brush | |||

| raw clothes | |||

| Heat-resistant stand (supplied with iron) or heat-resistant surface. | |||

| Before soldering a solder joint, make sure that there is no water left in the pipes, as this prevents the pipes from reaching the required temperature for effective soldering. | ||||

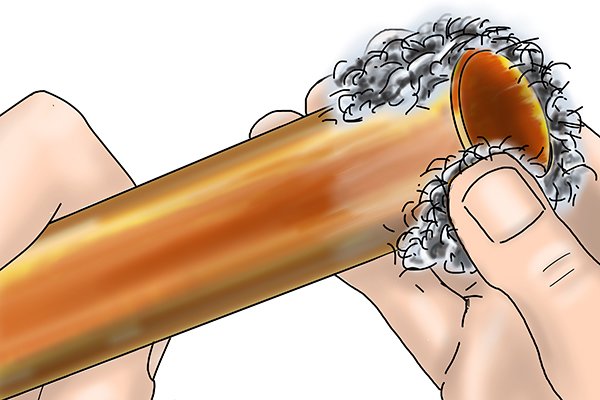

| Step 1 - ClearClean the outside of the pipe with a pipe cleaner, making sure all parts to be fluxed are well cleaned. | |||

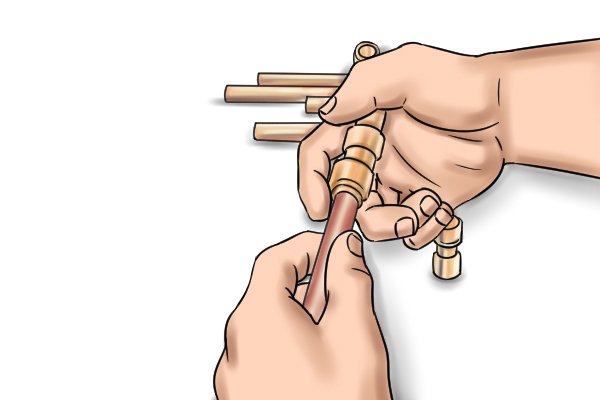

| Step 2 - Apply FluxApply the flux solution immediately after cleaning with a flux brush, making sure all cleaned parts are covered. | |||

| Step 3 - Connect the Pipes TogetherInsert the pieces of fluxed pipe into the solder fitting and screw on. | |||

| ||||

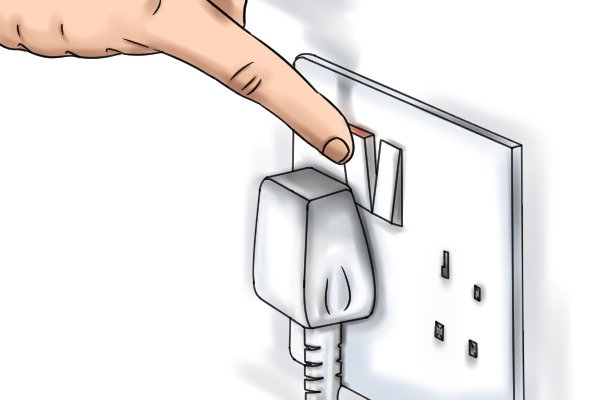

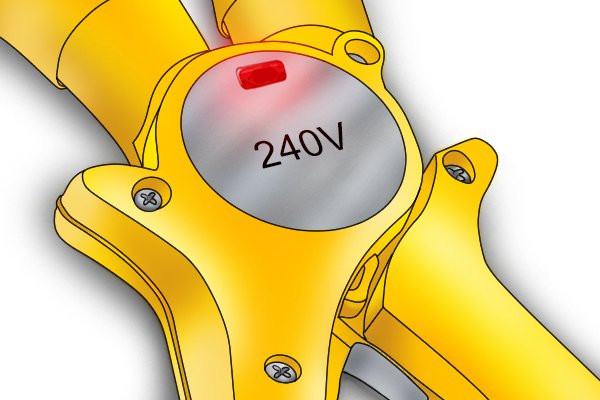

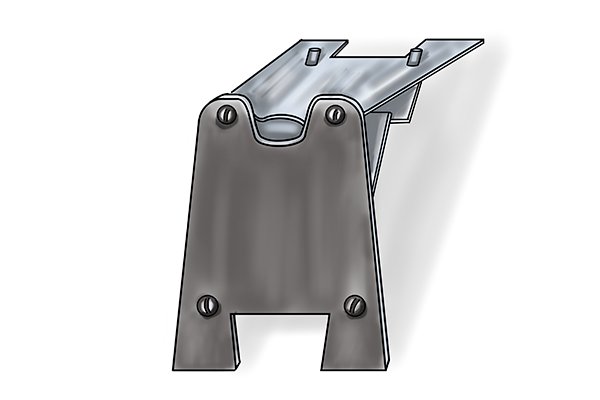

| Step 4 - Turn on the powerTurn on the plumbing iron, making sure it is either on its stand or on a heat-resistant surface. | |||

| Step 5 - Up to temperatureMake sure the sanitary iron is fully heated before using it. Some models may have an indicator light showing this. | |||

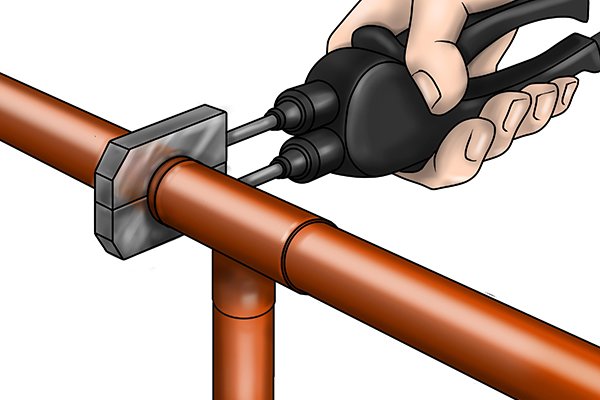

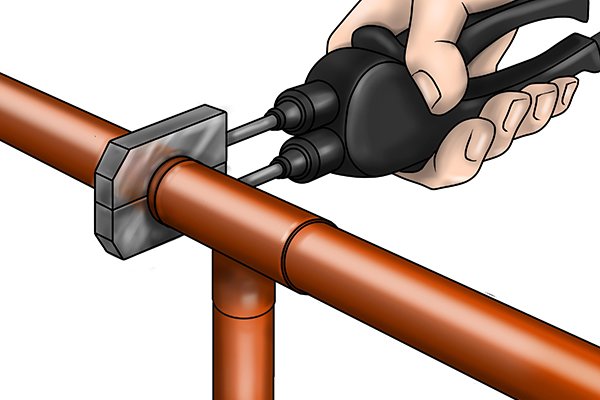

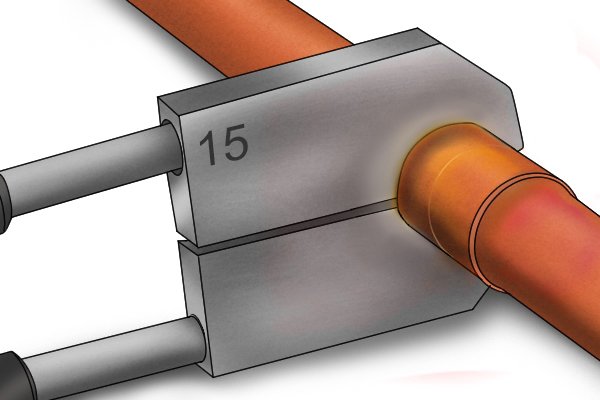

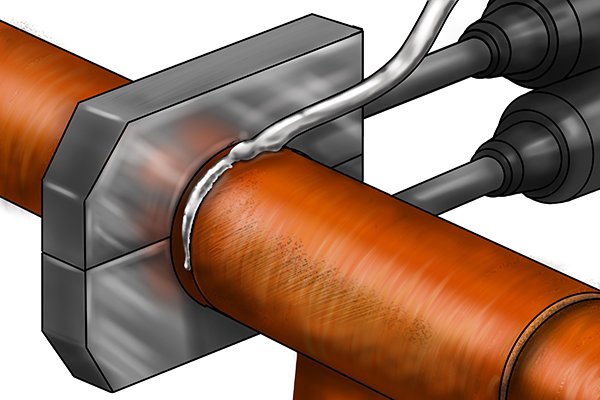

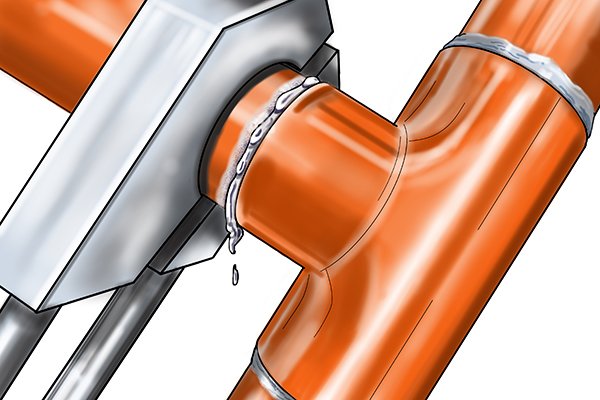

| Step 6 - Place the Heads on the PipeTake a plumbing iron and place the clamp heads on the pipe about 3 mm (1/8″) from the joint, this will prevent the solder from getting on the heads. | |||

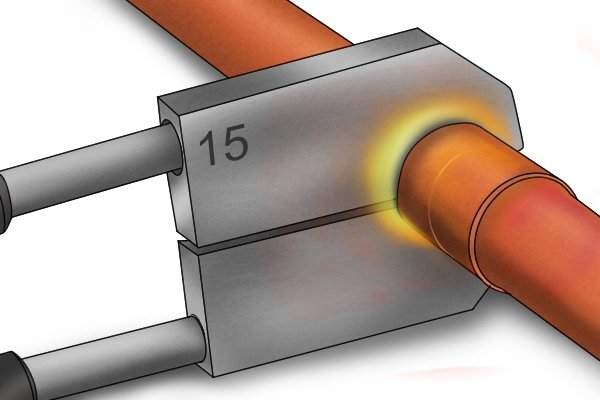

| Step 7 - Apply HeatApply heat to the pipe | |||

| Step 8 - Maintain Close ContactWhen heating the pipe, work with irons, make sure that the heads fit snugly against the surface of the pipe. This ensures that the pipe is heated to temperature and that all surfaces are heated. | |||

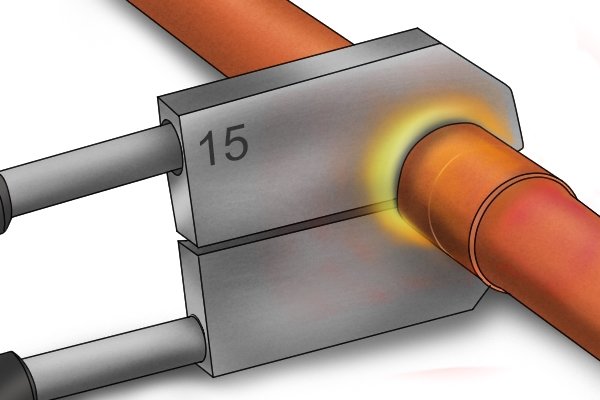

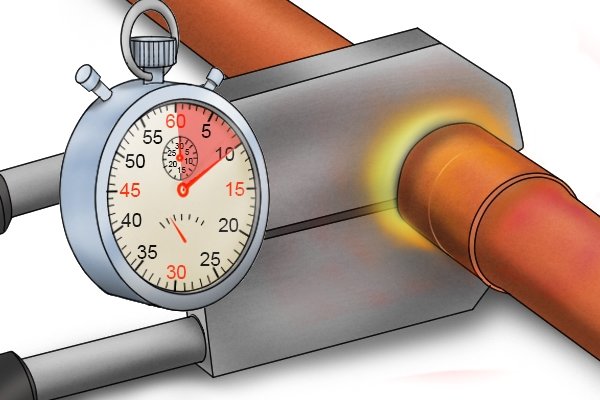

| Step 9 - Hold for 10 secondsHold the plumbing in place for at least 10 seconds; this allows the pipe to reach sufficient temperature. | |||

| Step 10 - Test HeatTo test if the pipe is hot enough, take a piece of solder wire and touch the tip near the joint. If the solder melts, the pipe is at the correct temperature and is ready to be soldered. | |||

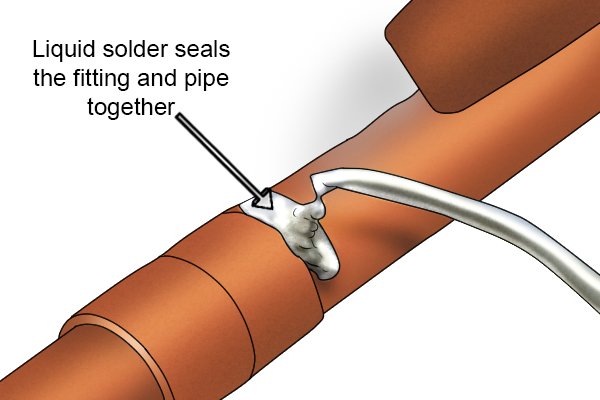

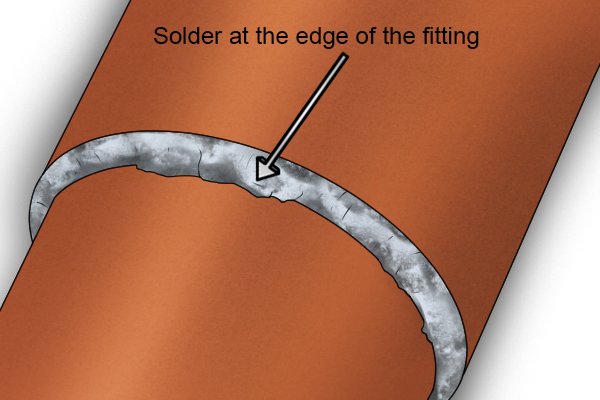

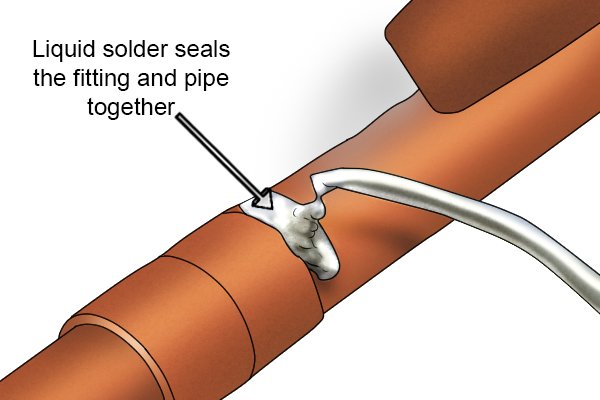

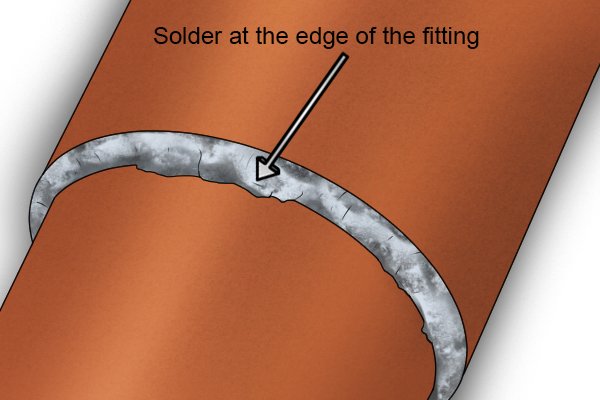

| Step 11 - Feeding the SolderIf the solder melts on contact, continue feeding the solder wire around the joint to create a seal. | |||

| Step 12 - Make a Neat ConnectionDon't apply too much solder. This will not make the connection more efficient and will only waste solder. | |||

| Step 13 - Place on a StandRemove the irons from the pipe and place them back on the stand until the next joint is ready for soldering, or turn off the tool if all joints are sealed. | |||

| Step 14 - Let coolAllow the pipe to cool, then wipe off excess flux with a damp cloth. | |||

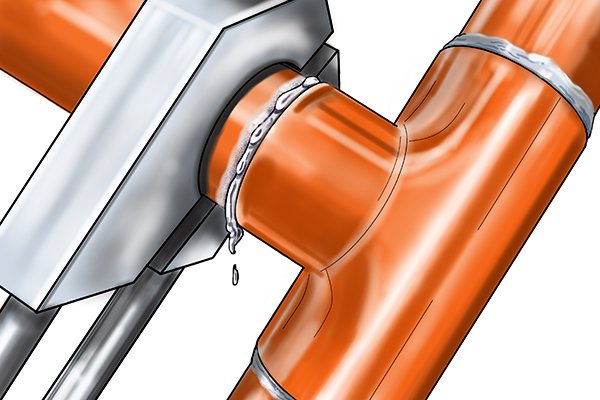

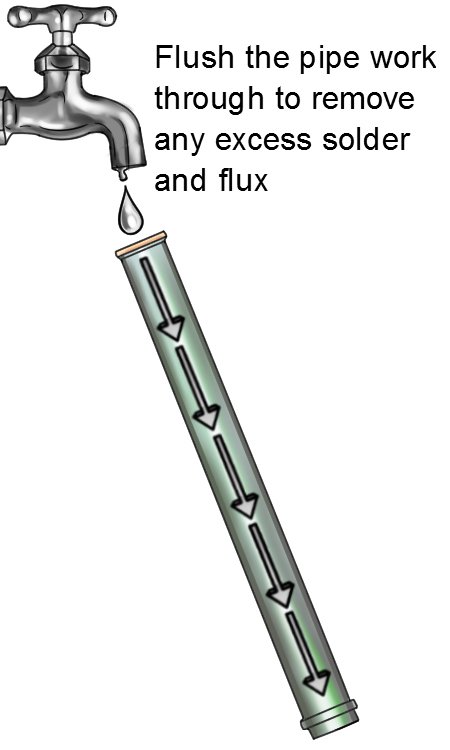

| Step 15 - Rinse and CheckOnce all soldering to the pipes has been completed, flush the pipes with clean water. This will remove any waste and flux residue from the pipes, as well as identify any potential leaks. | |||