How to check the Mass Air Flow Sensor (MAF) of an engine: 5 proven methods

Content

DMRV, mass air flow sensor, other names MAF (Mass Air Flow) or MAF is actually an air flow meter in the electronic fuel injection control system. The percentage of oxygen in the atmosphere is quite stable, therefore, knowing the mass of air entering the intake and the theoretical ratio between oxygen and gasoline in the combustion reaction (stoichiometric composition), you can determine the amount of gasoline you need at the moment by giving the appropriate command to the fuel injectors.

The sensor is not essential for the operation of the engine, therefore, if it fails, it is possible to switch to a bypass control program and further work with a deterioration in all vehicle characteristics for a trip to the repair site.

Why do you need an air flow sensor (MAF) in a car

To meet the requirements for ecology and economy, the electronic engine control system (ECM) must know how much air is drawn into the cylinders by the pistons for the current cycle of operation. This determines the estimated amount of time for which the gasoline injection nozzle will be open in each of the cylinders.

Since the pressure drop across the injector and its performance are known, this time is uniquely related to the mass of fuel supplied for combustion in one cycle of engine operation.

Indirectly, the amount of air can also be calculated by knowing the speed of rotation of the crankshaft, the displacement of the engine and the degree of opening of the throttle. This data is hardcoded in the control program or provided by the appropriate sensors, so the engine continues to work in most cases if the mass air flow sensor fails.

But determining the mass of air per cycle will be much more accurate if you use a special sensor. The difference in operation is immediately noticeable if you remove the electrical connector from it. All the symptoms of a MAF failure and the shortcomings of working on a bypass program will appear.

Types and features of the DMRV

There are many ways to measure mass air flow, three of them are used in a car with varying degrees of popularity.

Volume

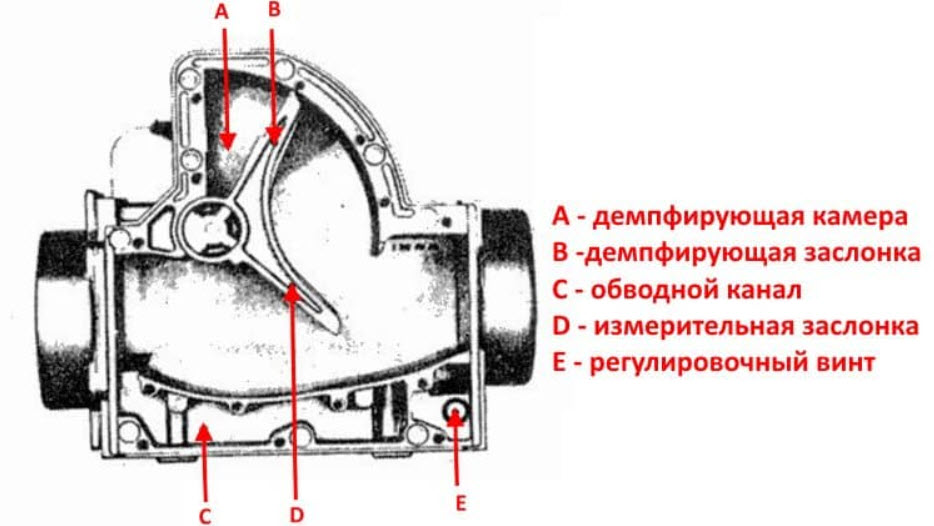

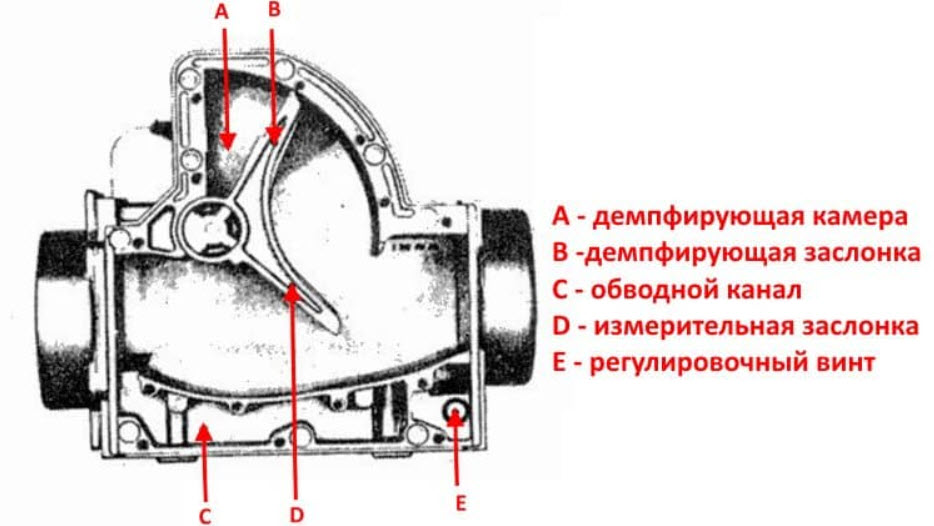

The simplest flow meters were built on the principle of installing a measuring blade in the cross section of the passing air, on which the flow exerted pressure. Under its action, the blade turned around its axis, where an electric potentiometer was installed.

It only remained to remove the signal from it and submit it to the ECM for digitization and use in calculations. The device is as simple as it is inconvenient to develop, since it is quite difficult to obtain an acceptable characteristic of the dependence of the signal on the mass flow. In addition, reliability is low due to the presence of mechanically moving parts.

A little more difficult to understand is the flow meter based on the Karman vortex principle. The effect of the occurrence of cyclic whirlwinds of air during its passage through an aerodynamically imperfect obstacle is used.

The frequency of these manifestations of turbulence depends almost linearly on the flow velocity, if the size and shape of the obstacle are correctly chosen for the desired range. And the signal is issued by an air pressure sensor installed in the turbulence zone.

At present, volumetric sensors are almost never used, giving way to hot-wire anemometric devices.

Wire

The operation of such a device is based on the principle of cooling a platinum coil heated by a fixed current when it is placed in an air stream.

If this current is known, and it is set by the device itself with high accuracy and stability, then the voltage on the spiral will depend with perfect linearity on its resistance, which, in turn, will be determined by the temperature of the heated conductive thread.

But it is cooled by the oncoming flow, so we can say that the signal in the form of voltage is proportional to the mass of air passing per unit time, that is, exactly the parameter that needs to be measured.

Of course, the main error will be introduced by the intake air temperature, on which its density and heat transfer ability depend. Therefore, a thermal compensating resistor is introduced into the circuit, which in one way or another from many known in electronics takes into account the correction for the flow temperature.

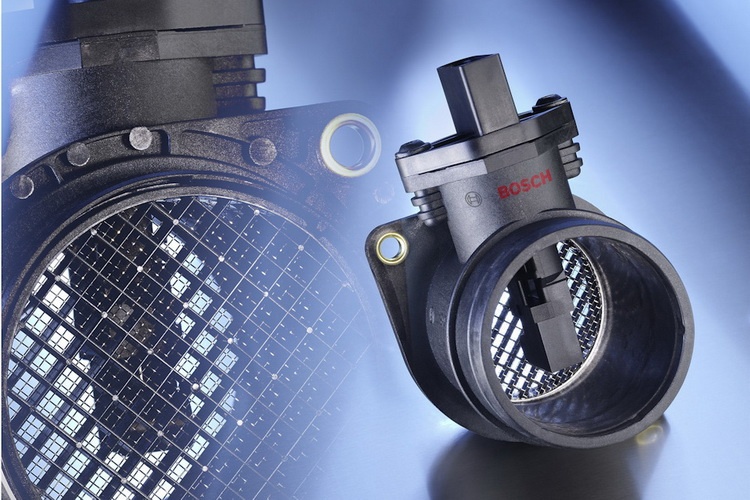

Wire MAFs have high accuracy and acceptable reliability, therefore they are widely used in manufactured cars. Although in terms of cost and complexity, this sensor is second only to the ECM itself.

Film

In a film MAF, the differences from a wire MAF are purely in design, theoretically it is still the same hot-wire anemometer. Only heating elements and thermally compensating resistances are made in the form of films on a semiconductor chip.

The result was an integrated sensor, compact and more reliable, although more difficult in terms of production technology. It is this complexity that does not allow for the same high accuracy that platinum wire gives.

But excessive precision for the DMRV is not required, the system still works with feedback on the oxygen content in the exhaust gases, the necessary correction of the cyclic fuel supply will be made.

But in mass production, a film sensor will cost less, and by its construction principle, it has greater reliability. Therefore, they are gradually replacing wire ones, although in fact both of them lose to absolute pressure sensors, which can be used instead of DMRV by changing the calculation method.

Symptoms of a malfunction

The impact of malfunctions in the operation of the DMRV on the engine is highly dependent on the specific vehicle. Some are even impossible to start if the flow sensor fails, although most simply degrade their performance and raise the idle speed when leaving the bypass subroutine and the Check Engine light is on.

In general, mixture formation is disturbed. The ECM, deceived by incorrect air flow readings, produces an inadequate amount of fuel, which causes the engine to significantly change:

- depletion or enrichment of the mixture leads to chaotic dips in engine thrust;

- idle speed jumps until it is set at a two to three times higher level after the MAF is excluded from consideration by the controller;

- fuel consumption increases and vehicle dynamics deteriorates;

- the control lamp is illuminated and it becomes possible to read the error code.

Watch this video on YouTube

The initial diagnosis of the MAF can be carried out using a scanner that is able to decipher errors in the ECM memory.

DMRV error codes

Most often, the controller issues the error code P0100. This means a MAF malfunction, to make such an output of the ECM causes the signals from the sensor to go beyond the possible range for a given period of time.

In this case, the general error code can be specified by additional ones:

- P0101 - clearly erroneous signal level, out of range;

- P0102 - low level in the signal circuit;

- P0103 - high level in the signal circuit;

- P0104 - unstable signal with errors.

It is not always possible to unambiguously determine a malfunction by error codes, usually these scanner data serve only as information for reflection.

In addition, errors rarely appear one at a time, for example, malfunctions in the DMRV can lead to a change in the composition of the mixture with codes something like P0174 and the like. Further diagnostics are carried out according to specific sensor readings.

How to check the MAF sensor

The device is quite complex and expensive, which will require care when rejecting it. It is better to use instrumental methods, although situations may be different.

Method 1 - external examination

The location of the MAF along the path of the air flow already behind the filter should protect the sensor elements from mechanical damage by flying solid particles or dirt.

But the filter is not perfect, it can be broken or installed with errors, so the condition of the sensor can first be assessed visually.

Its sensitive surfaces must be free of mechanical damage or visible contamination. In such cases, the device will no longer be able to give the correct readings and intervention will be required for repair.

Method 2 - power off

In unclear cases, when the ECM cannot unequivocally reject the sensor with the transition to bypass mode, such an action can be performed independently by simply turning off the engine and removing the electrical connector from the DMRV.

If the engine operation becomes more stable, and all its changes remain only typical for a software bypass of the sensor, for example, an increase in idle speed, then the suspicions can be considered confirmed.

Method 3 - check with a multimeter

All cars are different, so there is no single way to check the MAF with a multimeter voltmeter, but using the most common VAZ sensors as an example, you can show how this is done.

The voltmeter must have suitable accuracy, that is, be digital and have at least 4 digits. It must be connected between the instrument "ground", which is on the DMRV connector and the signal wire using needle probes.

Watch this video on YouTube

The voltage of the new sensor after the ignition is turned on does not quite reach 1 Volt, for a working DMRV (Bosch systems, Siemens is found, there are other indicators and methods) it is approximately in the range of up to 1,04 volts and should increase sharply when blowing, that is, starting and set of turns.

Theoretically, it is possible to call the sensor elements with an ohmmeter, but this is already an occupation for professionals who know the material part well.

Method 4 - checking with a scanner Vasya Diagnostic

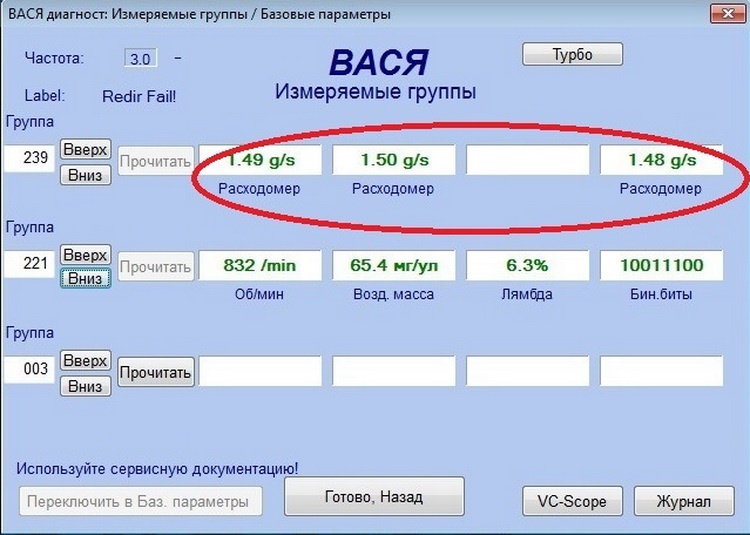

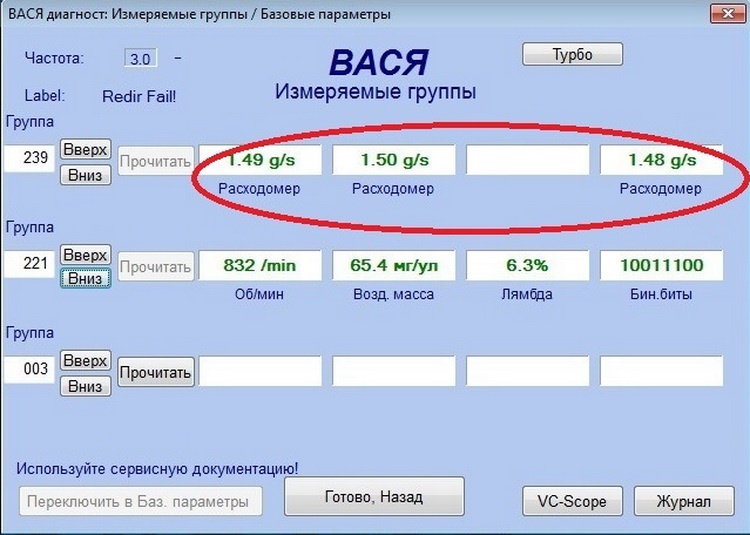

If there are no prerequisites for displaying the error code yet, but suspicions about the sensor have formed, then you can view its readings through a computer-based diagnostic scanner, for example VCDS, which is called Vasya Diagnostic in Russian adaptation.

The channels associated with the current air flow (211, 212, 213) are displayed on the screen. By transferring the engine to different modes, you can see how the MAF readings correspond to the prescribed ones.

Watch this video on YouTube

It happens that deviations occur only with a certain airflow, and the error does not have time to appear in the form of a code. The scanner will allow you to consider this in much more detail.

Method 5 - replacement with a working one

DMRV refers to those sensors, the replacement of which is not difficult, it is always in sight. Therefore, it is often easiest to use a replacement sensor, and if the engine operation returns to normal according to objective indicators or scanner data, then all that remains is to purchase a new sensor.

Usually, diagnosticians have a replacement for all such devices. You just need to make sure that the replacement device is exactly the same as it should be for this engine according to the specification, one appearance is not enough, you need to check the catalog numbers.

How to clean the sensor

Very often the only problem of the sensor is its contamination from a long service life. In this case, cleaning will help.

The delicate sensitive element will not tolerate any mechanical impact and then it will not show anything good to the controller. Pollution should simply be washed off.

Choice of purifier

You can try to find a special liquid, it exists in some manufacturers' catalogs, but it is easiest and most effective to use the most common carburetor cleaner in aerosol cans.

By washing the sensitive element of the sensor through the supplied tube, you can see how the dirt disappears before your eyes, usually such products are the most powerful in automotive pollution. In addition, it will treat fine measuring electronics quite carefully, without causing sudden cooling, such as alcohol.

How to extend the life of the MAF

The reliability and durability of the air flow sensor depends entirely on the state of this very air.

Watch this video on YouTube

That is, it is necessary to monitor and regularly change the air filter, avoiding its complete clogging, getting wet in the rain, as well as installation with errors when gaps remain between the housing and the filter element.

It is also unacceptable to operate an engine with malfunctions that allow reverse emissions into the intake duct. This also destroys the MAF.

Otherwise, the sensor is quite reliable and does not pose any problems, although its periodic monitoring on the scanner will be a good measure to maintain normal fuel consumption.