How to check the radiator cap

Content

How to check the radiator cap? This question is asked by drivers at different times of the year. After all, the operation of the radiator cap provides increased pressure in the internal combustion engine cooling system, which, in turn, makes it possible for the internal combustion engine to work normally and the interior stove to function in the cold season. Therefore, its condition must be regularly monitored, and when it is necessary to change the valve, the sealing ring, or the entire cover, since most often it is a non-separable structure. Therefore, in order to check how the cover works, one visual inspection is not enough, a pressure test is also needed.

How the radiator cap works

In order to better understand the essence of checking the radiator cap, first you need to discuss its structure and circuit. First of all, it should be noted that the antifreeze in the cooling system is under high pressure. This circumstance was made specifically in order to increase the boiling point of the coolant, since the operating temperature of the internal combustion engine slightly exceeds the traditional +100 degrees Celsius. Typically, the boiling point of antifreeze is around + 120 ° C. However, it depends, firstly, on the pressure inside the system, and secondly, on the state of the coolant (as the antifreeze ages, its boiling point also decreases).

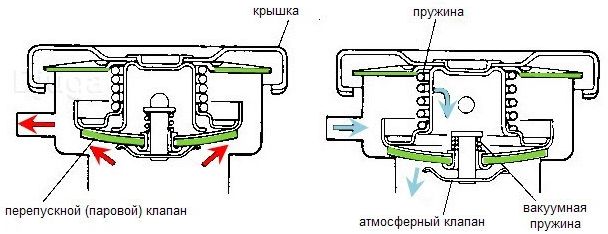

Through the radiator cap, not only is antifreeze poured into the radiator housing (although antifreeze is usually added to the expansion tank of the corresponding system), but the coolant converted into steam also enters the expansion tank through it. The device of the car radiator cap is quite simple. Its design involves the use of two gaskets and two valves - bypass (another name is steam) and atmospheric (another name is inlet).

The bypass valve is also mounted on a spring-loaded plunger. Its task is to smoothly control the pressure inside the cooling system. Usually it is about 88 kPa (it differs for different cars, and also depends on the operating conditions of the internal combustion engine for a particular internal combustion engine). The task of the atmospheric valve is the opposite. So, it is designed to ensure gradual equalization of atmospheric pressure and increased pressure inside the cooling system in a situation where the internal combustion engine is turned off and cools down. The use of an atmospheric valve provides two aspects:

- A sharp jump in the temperature of the coolant at the moment the pump stops is excluded. That is, heat stroke is excluded.

- The pressure drop in the system is eliminated at a time when the temperature of the coolant gradually decreases.

so, the listed reasons are the answer to the question, what affects the radiator cap. In fact, a partial failure of it usually leads to the fact that the boiling point of antifreeze decreases, and this can lead to its boiling during engine operation, that is, overheating of the internal combustion engine, which in itself is very dangerous!

Symptoms of a broken radiator cap

The car owner is advised to periodically check the condition of the radiator cap, especially if the car is not new, the condition of the cooling system is average or below this, and / or if water or antifreeze diluted with it was used as a coolant. also, the condition of the cover should be checked in the case when antifreeze is used in the cooling system for a very long time without replacing it. In this case, it may begin to corrode the rubber seal on the inside of the cover. A similar situation can arise, for example, when oil can get into the coolant when a cylinder head gasket is punctured. This process fluid is detrimental to the cap seal, and it also degrades the performance of the antifreeze.

the basic symptom of a breakdown in this case is a leak from under the radiator cap. And the stronger it is, the worse the situation, although even with the slightest leakage of liquid, additional diagnostics, repair or replacement of the cover must be carried out.

There are also several indirect signs that the radiator cap is not holding pressure in the cooling system. These include:

- the bypass valve plunger sticks (usually skewed) during the return movement for compression;

- weakening of the cover spring;

- when the atmospheric valve is pulled out of its seat (seat), it sticks and / or does not fully return to it;

- the diameter of the valve gasket is larger than the diameter of its seat;

- cracking (erosion) of rubber gaskets on the inner surface of the radiator cap.

The listed breakdowns can cause the radiator cap to let coolant (antifreeze or antifreeze) out. There are also a couple of indirect signs of cover failure. However, they can also indicate other, more serious, breakdowns in the cooling system. Yes, they include:

- when the bypass valve is stuck, the upper radiator pipe swells;

- when the atmospheric valve is stuck, the upper radiator hose retracts.

also if one or the other valve does not work properly, that the coolant level in the expansion tank will be the same. Under normal conditions, it should change (albeit slightly) depending on the temperature of the internal combustion engine.

How to check the operation of the radiator cap

You can check the health of the radiator cap in several ways. To do this, follow the algorithm below.

- Visual inspection. First of all, you need to visually check the condition of the cover. Ideally, it should not have mechanical damage, chips, dents, scratches, and so on. If these damages occur, then sooner or later a corrosion center will appear in their place, which will constantly expand. Such a cover can either be cleaned and repainted, or replaced with a new one. The second option is preferable.

- Spring check. The design of each radiator cap includes a spring that serves as part of the safety valve. To check, you need to squeeze it with your fingers. If it is squeezed very easily, it means that it is unusable and needs to be replaced (in case the lid is collapsible). However, most often the covers are non-separable, so it must be completely replaced.

- Atmospheric valve check. To check it, you need to pull it and open it. then let go and check to make sure it closes completely. also during the inspection process, it is imperative to check the valve seat for the presence of dirt or deposits in it, which may appear during the evaporation of the old antifreeze. If dirt or deposits are found, then there are two options. The first is to try cleaning the saddle. The second is to replace the cover with a new one. However, everything depends on the degree of contamination of the inner surface of the vacuum valve.

- Check valve actuation. To do this, you need to use a special device. About him a little further.

There is a so-called "folk" method for checking the condition of the radiator cap. It consists in the fact that, on a warmed-up (switched on) internal combustion engine, feel the radiator pipe. If there is pressure in it, then the lid is holding, and if the pipe is soft, then the valve on it is leaking.

However, there is also a description of one "folk" method, which is actually incorrect. So, it is argued that you need to squeeze the upper pipe with your hand, while at the same time observing an increase in the liquid level in the expansion tank. Or, similarly, by dismantling the end of the outlet pipe, observe how the antifreeze will flow out of it. The fact is that the liquid column lifts the valve seat only in a situation where the pressure from the compression force will be much greater. In fact, as the pressure increases, the liquid presses in all directions, and will only lift the bypass valve “in excess”. And the pressure of the coolant is distributed through all channels, and not just in one particular one (to the seat).

Checking the lid with improvised means

Checking the operation of the bypass valve is quite simple. To do this, you need to disconnect any small pipe of the cooling system on the internal combustion engine, for example, heating the damper or manifold. then you need to use a compressor with a pressure gauge (in order to know the exact supply pressure), you need to supply air to the system. The pressure value at which the valve operates will be easily determined by the hissing and gurgling coming from the elements of the cooling system. Please note that at the end of the procedure, the pressure cannot be abruptly released. This threatens that when the lid is opened, the antifreeze may splash out under pressure. Under normal conditions, the atmospheric valve is designed to prevent this.

From the expansion tank, the liquid enters the radiator through the check valve. It retains pressure from the radiator side, but quietly opens if there is a complete vacuum there. It is checked in two stages:

- You need to try to lift the valve patch with your finger. Ideally, it should move with minimal effort (no mechanical resistance).

- On a cold internal combustion engine, when there is no excess pressure in the radiator, you need to install a plug in its seat. then disconnect the tube going to the expansion tank of the cooling system and through try to "inflate" the radiator. The valve is designed for low pressure, so you will probably be able to blow a small amount of excess air into the radiator. This can be checked by unscrewing the radiator cap again. In this case, a characteristic hissing sound of air emanating from it should be heard. Instead of a mouth, a compressor with a pressure gauge can also be used. However, care must be taken to ensure that the pressure does not grow sharply.

Cover Gasket Check

Together with the valves, it is worth checking the tightness of the upper gasket of the radiator cap. Even when air whistles out when the lid is opened, this only indicates that the valve is working. However, through a leaky gasket, antifreeze can gradually evaporate, due to which its level in the system drops. At the same time, the reverse process also appears, when, instead of picking up antifreeze from the expansion tank, air from the atmosphere enters the system. This is how an air lock is formed (“airing” the system).

You can check the plug in parallel with checking the check valve. In its original position, it must be installed in its place on the radiator. To check, you need to “inflate” the radiator through the tube coming from the expansion tank (however, the pressure should be small, about 1,1 bar), and close the tube. You can just listen to the hiss of the outgoing air. However, it is better to produce a soapy solution (foam), and coat the cork around the perimeter (in the area of \uXNUMXb\uXNUMXbthe gasket) with it. If air comes out from under it, it means that the gasket is leaky and needs to be replaced.

Radiator cap tester

Many car owners who are faced with a depressurization of the cooling system are interested in the question of how to check the performance of the radiator cap using special testers. Such a factory device costs more than 15 thousand rubles (as of the beginning of 2019), so it will be available only for car services and car repairmen on an ongoing basis. Ordinary car owners can produce a similar device from the following components:

- A bad radiator from any old car. Its general condition is unimportant, the main thing is that in order for it to have a whole upper tank. Especially the part where the cork is attached.

- Sandpaper and "cold welding".

- Nipple from the machine chamber.

- Compressor with accurate pressure gauge.

Omitting the details of the manufacture of the device, we can say that it is a cut off upper radiator tank, on which all the cells were drowned out so that air would not escape through them, as well as side walls with a similar purpose. The nipple of the machine chamber, to which the compressor is connected, is hermetically attached to one of the side walls. then the test cover is installed in its seat, and pressure is applied with the help of a compressor. According to the readings of the pressure gauge, one can judge its tightness, as well as the performance of the valves built into it. The advantage of this device is its low cost. Disadvantages - the complexity of manufacturing and non-universality. That is, if the cover differs in diameter or thread, then a similar device must be made for it, but from another unusable radiator.

With a radiator cap tester, you can check their operating pressure range. It will be different for different engines. namely:

- Gasoline engine. The opening pressure value of the main valve is 83…110 kPa. The opening pressure value of the vacuum valve is -7 kPa.

- Diesel engine. The opening pressure value of the main valve is 107,9±14,7 kPa. The closing pressure of the vacuum valve is 83,4 kPa.

The given values are averages, but it is quite possible to be guided by them. You can find exact information about the operating pressures of the main and vacuum valves in the manual or on specialized resources on the Internet. In the event that the tested cap shows a pressure value that differs greatly from that given, it means that it is faulty and, therefore, requires repair or replacement.

Radiator cap repair

Repairing the radiator cap is often impossible. More precisely, the result will most likely be negative. So, you can independently try to replace the rubber gaskets on the lid, clean the rust on its body, and repaint it. However, if the spring in the design is weakened or one of the valves (or two at once) fails, then their repair is hardly possible, since the body itself is in most cases non-separable. Accordingly, the best solution in this case would be to purchase a new radiator cap.

Which radiator cap to put on

Many motorists who have started checking and replacing the said cover are interested in the question of what are the best radiator covers? Before answering this question, you need to immediately pay attention to the fact that the new cover must have the same performance characteristics as the one being replaced. namely, have the same diameter, thread pitch, size of the internal valve, and most importantly - must be designed for the same pressure.

Usually, for most modern passenger cars, covers are sold that are designed to operate in the pressure range of 0,9 ... 1,1 Bar. However, before buying, you need to further clarify this information, since sometimes there are exceptions. Accordingly, it is necessary to make a choice of a new cover with similar characteristics.

Please note that you can also find so-called tuned radiator caps on sale, designed to work at elevated pressures, namely up to 1,3 bar. This is done in order to also increase the boiling point of antifreeze more and thereby increase the efficiency of the car's internal combustion engine. Such covers can be used on sports cars, the engines of which are designed to operate at high power, but for a short period of time.

For ordinary cars used in the urban cycle, such covers are categorically not suitable. When they are installed, a number of negative factors appear. Among them:

- The work of the elements of the cooling system "for wear". This leads to a decrease in their total resource and the risk of premature failure. And if a pipe or clamp bursts from excessive pressure, this is half the trouble, but this situation can end much worse, for example, if a radiator or expansion tank bursts. This already threatens costly repairs.

- Reduced antifreeze resource. Any coolant has a certain operating temperature range. Going beyond it reduces the performance of antifreeze and significantly reduces the time of its use. Therefore, when using tuned covers, you will have to change antifreeze more often.

so, it's best not to experiment, and follow your vehicle's manufacturer's recommendations. As for specific brands of radiator caps, there are quite a lot of them, and they are different for different cars (for European, American, Asian cars). It is best to buy original spare parts. Their article numbers can be found in the documentation or on special resources on the Internet.

Hack and predictor Aviator

Remember that a serviceable radiator cap is the key to the normal operation of the internal combustion engine of any car with a closed cooling system. Therefore, it is worth checking its condition not only when it failed (or problems began in the operation of the cooling system), but also periodically. This is especially true for older machines, and/or machines that use water or diluted antifreeze in the cooling system. These compounds eventually damage the cover material, and it fails. And the breakdown of its individual parts threatens to reduce the boiling point of the coolant and overheat the internal combustion engine.

it is necessary to select a new cover according to previously known parameters. This applies both to its geometric dimensions (lid diameter, gasket diameter, spring force) and the pressure for which it is designed. This information can be found in the manual or simply buy a radiator cap similar to the one installed before.