How to check the thrust bearing

Content

When breakdowns appear in the front suspension of a car, one of the first measures that its owner should take is check the thrust bearinglocated between the support and the upper cup of the spring. To do this, you need to grab the “cup” of the rack with your hand (put your hand on the support) and shake the car. Constant sharply changing loads, including shock loads, in combination with abrasive dust particles, contribute to the wear of the components of the support leg bearing and, ultimately, completely disable it. As a result, it begins to play, knock, creak or squeak, and the shock absorber rod will deviate from its axis.

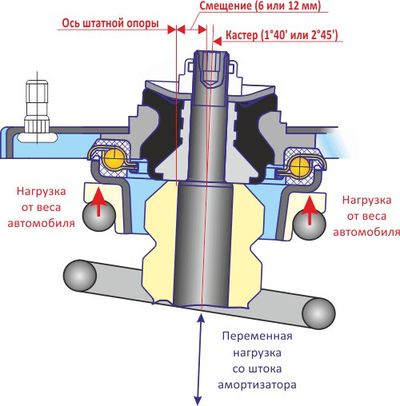

Diagram of the support bearing

Such problems with its operation can lead to more serious consequences in the suspension of the car. Since the wear of the support bearing will lead to a violation of the wheel alignment angles, and consequently, a deterioration in the handling of the car and accelerated tire wear. How to check, and which manufacturer of thrust bearings to prefer when replacing - we will talk about all this in more detail.

Signs of a broken support bearing

The main sign of a breakdown, which should alert the driver, is knocking in the area of the front left or right side members. In fact, other suspension parts can also be sources of knocking and creaking, but you need to start checking with the “support”.

Unpleasant sounds are especially characteristic when driving on rough roads, through pits, on sharp turns, with a significant load on the car. That is, in conditions of critical operation of the suspension. In addition, the driver will probably subjectively feel a decrease in the controllability of the car. The steering does not respond so quickly to its actions, a certain inertia appears. also the car starts to “scour” along the road.

Causes of breakage

The main causes of failure of thrust bearings are dust and water penetrating inside, lack of lubrication there, and also not infrequently, due to a strong blow to the rack. About these and other causes of failure of the thrust bearing in more detail:

- Natural wear of the part. Unfortunately, the quality of domestic roads leaves much to be desired. Therefore, when operating a car, be prepared for the fact that the bearings will be subject to more wear than their manufacturer claims.

- Ingress of sand and dirt into the mechanism... The fact is that the thrust bearing is a type of rolling bearing, and it is not structurally provided for protection against the mentioned harmful factors.

- Sharp driving style and non-compliance with the speed limit. Driving on bad roads at high speed leads to excessive wear not only of the support bearing, but also of other elements of the car's suspension.

- Poor quality parts or defects. This is especially true for bearings of domestic production, namely, for VAZ cars.

Front support device

How to check the thrust bearing

then we will consider the question of how to determine the failure of the support bearing with your own hands by a characteristic feature. Producing this is easy enough. in order to recognize how to knock thrust bearings, there are three methods for checking the “support” at home:

- you need to remove the protective caps and press the upper element of the front strut rod with your fingers. After that, swing the car from side to side by the wing (first in the longitudinal and then in the transverse direction). If the bearing is bad, you will hear the familiar thud you heard when driving the car on rough roads. In this case, the car body will sway, and the rack will either stand still or move with a smaller amplitude.

- Place your hand on the coil of the front shock spring and have someone sit behind the wheel and turn the wheel from side to side. If the bearing is worn out, you will hear a metallic knock and feel a recoil with your hand.

- You can focus on sound. Drive your car on rough roads, including speed bumps. With a significant load on the suspension system (sharp turns, including at high speed, moving bumps and pits, sudden braking), a metallic knock of thrust bearings will be heard from the front wheel arches. You will also feel that the car's handling has deteriorated.

Checking "defensive cars" at VAZs

How the thrust bearings knock

To extend the service life of this bearing, very often, if the design allows it, auto repairmen wash and change the lubricant. If the part is partially or completely out of order, then the support bearing is not repaired, but replaced. In this regard, a logical question arises - which support bearings are better buy and deliver?

Repair of the support bearing Ford Mondeo

Detailed photo instructions on how to independently restore the performance of a Ford Mondeo support bearing. Do-it-yourself repair of the support bearing of the Ford Mondeo shock absorber strut Read more

Shock absorber (car shock absorbers)

The shock absorber ensures safety and comfort when driving by absorbing impacts, jolts, and vibrations of moving suspension elements. Therefore, it is important to eliminate shock absorber problems in a timely manner - to maintain them correctly and replace them in a timely manner. More details

Checking car shock absorbers

This video shows the consequences of faulty shock absorbers, and also describes popular testing methods: swaying, behavior on the road, what to look for during visual diagnostics Read more

How to choose pillow block bearings

Support bearing

So, today in the auto parts market you can find “supports” from different manufacturers. It is best, of course, to buy original spare parts that are recommended by the manufacturer of your car. However, most car owners, as an alternative, buy non-original bearings in order to save money. And then there is a kind of lottery. Some manufacturers (mainly from China) produce quite decent products that can, if not compete with original spare parts, then at least come close to them. But there is a danger of buying a frank marriage. Moreover, the probability of buying a low-quality bearing is much higher. We present for you information about popular brands of thrust bearings, reviews of which we managed to find on the Internet - SNR, SKF, FAG, INA, Koyo. When buying branded products always pay attention to the presence of branded packaging. It, in fact, is an analogue of a passport for a bearing, which is usually issued by domestic manufacturers.

SNR - support and other bearings are produced under this brand in France (some production facilities are located in China). The products are of high quality and are used by various car manufacturers in Europe (such as Mercedes, Audi, Volkswagen, Opel, etc.) as an original.

| Positive reviews | Negative feedback |

| SNR bearings are of very high quality, if they are properly looked after, they will give you twice as much of their life as specified by the manufacturer. These bearings have very good carburizing of the working surface, if it is not overheated and lubricated, it becomes indestructible. | Unfortunately, after six months, it failed me - it began to buzz noticeably. Prior to this, the car drove for 8 years on factory bearings, until after falling into the pit, the right one flew. I operated the new bearing from May to October on a wheel with a cast balanced disc, then I changed the shoes to a new balanced forging with winter tires, and in February the buzz began. I didn’t get into the pits, I didn’t exceed the speed, the disk and tires are in order, and this SNR was ordered to be urgently changed during maintenance. |

| I have installed SNR bearings many times and have never had any problems. They get into place without problems, the mileage is excellent. The margin of safety is clearly decent, since even if the bearing fails, it also leaves quite a lot of time to find a new one and replace it. Noise prompts, but goes. | Like many car enthusiasts, I often have to deal with the problem of spare parts. Of course, I want to buy something that is not expensive and of high quality, but as often happens, these two factors are not comparable. What can not be said about the SNR bearing. A relatively inexpensive bearing, and with proper operation, it can even last its entire life, but it’s better not to risk it, of course - you left as much as it should be, take it off and put on a new one. |

SKF Is an international engineering company from Sweden, the world's largest manufacturer of bearings and other automotive parts. Its products belong to the top price segment and are of high quality.

| Positive reviews | Negative feedback |

| In general, these bearings are time-tested, quite suitable for installation. Unless, of course, you are satisfied with the standard support, and in general the car's suspension. The only negative is not everywhere and not always you can buy. | Everyone here praises GFR, but I will say: a bearing without lubrication or slightly lubricated does not find much and GFR makes good money on it. They have poor quality. |

| SKF is a proven, reliable brand. I changed the bearing, I took it from this manufacturer, it serves flawlessly ... | - |

FAG is a manufacturer of bearings and other spare parts for mechanical engineering. Products are distinguished by reliability, quality, and belong to an expensive price segment.

| Positive reviews | Negative feedback |

| Bearings fully meet their price. Yes, they are expensive, but they last a very long time. Even on our dead roads. | No negative reviews found. |

| These are on my Mercedes M-class. Changed under warranty. No problem. | - |

INA Group (INA - Schaeffler KG, Herzogenaurach, Germany) is a privately held German bearing company. It was founded in 1946. In 2002, INA acquired FAG and became the world's second largest bearing manufacturer.

| Positive reviews | Negative feedback |

| I took a chance and bought. I will not lie. The first 10 thousand occasionally listened to the bearing. But it worked smoothly and did not make any extraneous sounds. Another replacement came and I was pleasantly surprised that the bearing did not let me down on the road and went 100 thousand kilometers. | There have been a lot of complaints about Ina's products lately. I also had an Ina thrust bearing from the factory on Toyota, but when replacing it, I put another one. |

| With its quality, this company has established itself as an excellent and reliable manufacturer. It feels like the bearing is made of quality materials. During operation, I did not find any complaints at all. Usually after installation I forgot about it for a very long time. | I put it on my Peugeot, drove 50 thousand and the bearing rattled. It seems to be okay, but there is no more trust in this company, it is better to take such things from an authorized dealer. |

Koyo is a leading Japanese manufacturer of ball and roller bearings, lip seals, machine steering mechanisms and other equipment.

| Positive reviews | Negative feedback |

| I took myself to replace the old, killed original. From myself I will say that it is quite a good analogue for the money. Been running for 2 years now with no problems. Of the substitutes, as for me, this is the best option, since I heard somewhere that the original spare parts are supplied by this particular company, so it seemed to me that the choice is obvious. How he will behave in the future is unknown, but I hope that everything will be fine. | No negative reviews found. |

| Hello motorists and everyone)) I found a knock in my car, ran diagnostics and realized that I needed to change the thrust bearing before it flew. I wanted to order an original KFC, but it cost a lot, so I changed my mind) I bought a Koyo front wheel bearing. Ordered from Moscow. | - |

The choice of one or another manufacturer should be based, first of all, on whether the bearing is suitable for your car. In addition, try not to buy cheap Chinese fakes. It is better to buy a branded part once that will last you a long time than to overpay for cheap stuff and suffer with its replacement.

Hack and predictor Aviator

Partial or complete failure of the support bearing not a critical failure. However, we still strongly recommend that you carry out their diagnostics every 15 ... 20 thousand kilometers, regardless of the presence of signs of its breakdown. So you, firstly, save on expensive repairs of other suspension elements, such as shock absorbers, tires (treads), springs, connecting and steering rods, tie rod ends.

And secondly, do not let go down level of control of your car. The fact is that worn bearings have a bad effect on axle geometry and wheel angle settings. Consequently, with rectilinear movement, you have to constantly “tax”. Because of this, the wear of the shock absorber mount increases by approximately 20%.