How to check airbags

Content

Taking into account the fact that the supports (they are also pillows) of the internal combustion engine serve on average 80-100 thousand kilometers, it is not surprising that many car owners are not familiar with the breakdown of these parts. But if the car is no longer new, and increased vibrations have appeared in the engine compartment, then you should think about how to check the internal combustion engine cushions.

We will analyze here all the main points regarding the diagnosis of breakdowns and methods of verification. In brief, information on how pillows are checked is collected in the table, and below we will consider in detail any of their methods. If you are first interested in “what it looks like”, “where it is located” and “why it is needed”, then check out the article about ICE supports.

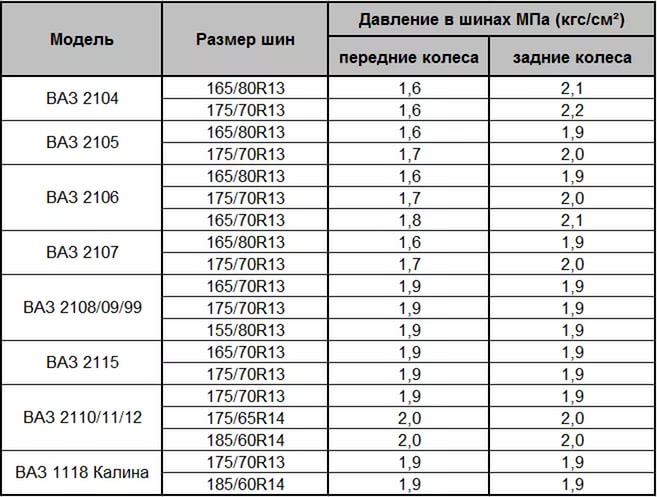

| How can you check | Rubber-metal cushions | Hydraulic supports with mechanical control | Hydraulic supports with electronic vacuum control |

|---|---|---|---|

| External inspection of the engine compartment | ✔ | ✔ | ✔ |

| External inspection from below the car | ✔ | ✔ | ✔ |

| Method for checking the vibration of a car with automatic transmission | ✔ | ||

| Vacuum hose test method | ✔ |

When do you need to check the pillows of the internal combustion engine

How do you understand that you need an internal combustion engine airbag diagnostic? The signs of damage to this part are as follows:

Damaged motor mount

- vibration, possibly strong, that you feel on the steering wheel or car body;

- knocks from the engine compartment, which are audible even at idle;

- transmission shocks while driving (especially on automatic machines);

- bumps under the hood when driving over bumps;

- intensifying vibrations, shocks, knocking when starting off and braking.

therefore if your car “kicks”, “trembles”, “knocks”, especially during the change of engine modes, gear shift, pulling away and braking to a stop, then the problem is probably in the engine cushion.

How to check the engine support

There are several basic methods for checking ICE pillows. Two are universal and are used both for diagnosing traditional rubber-metal ICE bearings and for hydraulic bearings. If you have a Toyota, Ford or another foreign car on which hydraulic supports are installed, then checking the performance of the internal combustion engine pillows can be performed by other methods, including even using a smartphone. Let's consider them all in detail.

Checking the rubber-metal cushions of the internal combustion engine

The first method, which will help determine the breakdown - the simplest, but the least informative. Open the hood, ask the assistant to start the engine, and then slowly move off, driving literally 10 centimeters, then turn on the reverse gear and move back. If the internal combustion engine changes its position as a result of changing the driving modes of the car, or it vibrates too much, most likely the problem is in the pillows. Best of all, this method is suitable for checking the right, it is also the top, engine support - it is clearly visible under the hood. However, several pillows can fail at once or a problem with the lower support, so it's worth moving on to the next option.

It will help to verify the violation of integrity and check the condition of all pillows second method. For him, you will need a pit or overpass, a jack, a support or support, a mount or a strong lever. Then follow the algorithm.

- Raise the front of the car with a jack (if you have a rear engine, then the rear).

- Support the raised machine with props or a support/block.

- Use the released jack to hang the engine and remove its weight from the supports.

- Examine the engine mounts for damage.

Checking the hydraulic cushion with the engine running

Visual inspection of the rubber-metal support

What can you see when examining them? Traces of destruction or damage to the structure, ruptures, cracks, delamination of the rubber layer, delamination of rubber from the metal part. During the inspection, special attention should be paid to the junctions of rubber with metal.

If a visual inspection did not give results, then one procedure should also be carried out. Ask an assistant to take a pry bar or lever and slightly move the engine around each of the pillows. If there is a noticeable play at the attachment point, you just need to tighten the mount of the supports. Or by such actions you will be able to identify the separation of the rubber support from its metal part.

Method for determining the source of vibration

If the inspection does not help, and the vibrations continue, you can use the method described in this video. In order to accurately determine the origin of vibration, because it can come not only from the internal combustion engine, but also from the gearbox, exhaust pipe, or the protection touching the crankcase, service station specialists use a jack with a rubber pad. The device will replace the support, taking the entire load on itself. By alternately hanging the motor at points close to the native supports, they determine where the vibration disappears during such manipulations.

How to check ICE pillows on a VAZ

If we talk about the most popular VAZ cars, for example, model 2170 (Priora), then all the pillows in it are ordinary, rubber-metal. Even modern Lada Vesta does not use hydrosupports. Therefore, for “vases”, only the external inspection of the airbags described above is relevant, but only if standard supports are installed, and not upgraded ones, since there are alternative options from third-party manufacturers, or airbags that are suitable from other cars. For example, on Vesta, as a replacement for the original right cushion (article 8450030109), a hydraulic support from BMW 3 in the body of E46 is used (article 2495601).

The characteristic features of the “dead” VAZ ICE pillows are:

- too strong and sharp jerks of the motor;

- steering wheel twitches at high speeds;

- knocks out gears while driving.

How to check the right, rear, front, left engine airbags

Depending on the design of the car, the pillows in it can be installed in different places. For example, in VAZ 2110-2112 cars, an upper support (known as a “guitar”), side right and side left, as well as rear pillows are used. Most Mazda vehicles have right, left and rear mounts. Many other cars (for example, Renault) have - right, front and rear.

Most often, it is the right pillow that is installed in the upper part of the car, which is why it can also be called the top one. Therefore, the first verification method, without a pit, is best suited specifically for the right (upper) support. The second method is for the front and rear pads that hold the ICE underneath.

Note separately the peculiarity that in different car models not all pillows can be of the same type. It often happens that the supports are hydraulic in the upper part, and rubber-metal in the lower part. In expensive cars, all supports are hydraulic (they can also be called gel). You can check them using the methods that will be described below.

How to check ICE airbags video

Checking and replacing the right pillow ICE Logan

Checking and replacing engine bearings on VAZ 2113, 2114, 2115

Checking the hydraulic cushion of the internal combustion engine

Swing and vibrate method The internal combustion engine at startup is also relevant for checking hydraulic (gel) cushions, but it is also worth inspecting their body for hydraulic fluid leaks. You need to look both at the top of the support, where there are technological holes, and at the bottom, where it can wear out. This applies to any hydraulic cushions - both with mechanical control and with electronic vacuum.

Failed hydraulic cushions are much easier to identify than conventional ones. It will not be possible not to notice the shaking of the internal combustion engine, knocks, vibration on the body at startup, driving over bumps and passing a speed bump, or recoil on the gearshift knob. it is also easier to detect play in the vertical and horizontal direction when loosening a jacked-up internal combustion engine with a mount.

The easiest method, with which you can check the serviceability of the upper right hydraulic cushion - by setting the car on the handbrake, give it a lot of gas. Deviations of the internal combustion engine and the stroke in the support can be noticed by any driver.

Checking the hydraulic bearings of the internal combustion engine

Next way suitable for vehicles with hydraulic engine mounts on vehicles with automatic transmission. It will require a smartphone with an installed vibration measurement program (for example, Accelerometer Analyzer or Mvibe). First turn on the drive mode. Then look on the screen to see if the vibration level has increased. Then do the same in reverse gear. Determine in which mode the internal combustion engine vibrates more than usual. Then ask the assistant to sit behind the wheel, while you yourself look at the internal combustion engine. Let it turn on the mode in which the vibrations have intensified. Pay attention to which side the motor sags at this moment - it is this pillow that is damaged.

also one test method suitable for vehicles exclusively with hydraulic mounts that use electronic-vacuum control of the cushions. To do this, you need to start the internal combustion engine, and it is better to open the oil filler cap, so the knocks of the internal combustion engine are heard more clearly. Then you need to find the vacuum hoses that go to each of the pillows. The right one is usually accessed from above by simply opening the hood (as in this video). We remove the pillow hose, clamp it with a finger - if the knock disappears, then there is a gap in the pillow and there is a depressurization, so it knocks.

What can happen if you do not change faulty supports

What will happen if you do not pay attention to possible breakdowns of the internal combustion engine pillows? At first, when vibration and knocking are imperceptible, nothing critical will happen. But with the destruction of the ICE pillows, the power unit will begin to transmit vibrations to the chassis parts and they will begin to fail much faster, which could be under the same operating conditions. also, the motor can beat against the elements of the engine compartment and damage various pipes, hoses, wires and other parts. And the state of the internal combustion engine itself can suffer due to constant blows that are not extinguished by anything.

How to extend the life of ICE pillows

ICE pillows work most of all at the moments of the strongest vibrations of the motor. This is primarily starting off, accelerating and braking. Accordingly, a driving mode with a soft start and fewer sudden accelerations and stops prolongs the life of the internal combustion engine mounts.

Of course, these parts last longer on good roads, but it is very difficult for us to influence this factor. As well as for launches in sub-zero temperatures, when the rubber hardens and tolerates vibrations worse. But in general, we can say that a neat and calm ride can extend the life of many parts, including the ICE cushions.