How an automatic transmission works

Content

An automatic transmission allows a car's engine to operate within a narrow range of speeds, just like a manual transmission. As the engine reaches higher degrees of torque (torque is the amount of rotational power of the engine),…

An automatic transmission allows a car's engine to operate within a narrow range of speeds, just like a manual transmission. As the engine reaches higher levels of torque (torque is the engine's rotational power), the gears in the transmission allow the engine to take full advantage of the torque it generates while maintaining an appropriate speed.

How important is a transmission to a car's performance? Without a transmission, vehicles only have one gear, it takes forever to reach higher speeds, and the engine wears out quickly due to the high RPMs it constantly produces.

Principle of automatic transmission

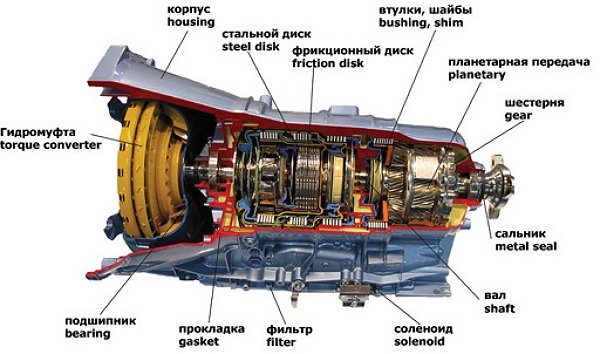

The principle of operation of an automatic transmission is based on the use of sensors to determine the appropriate gear ratio, which largely depends on the desired vehicle speed. The transmission connects to the engine in the bell housing, where a torque converter converts the engine's torque into driving force, and in some cases even amplifies that power. The transmission's torque converter does this by transferring that power to the driveshaft via the planetary gear and clutch discs, which then allow the car's drive wheels to rotate to propel it forward, with different gear ratios required for different speeds. Depending on the brand and model, these are rear-wheel drive, front-wheel drive and all-wheel drive vehicles.

If the vehicle only had one or two gears, reaching higher speeds would be a problem because the engine only spins at a certain RPM depending on the gear. This means lower revs for lower gears and therefore lower speed. If the top gear was second, it would take the vehicle forever to accelerate to lower rpm, gradually revving up as the vehicle picked up speed. Engine stress also becomes a problem when running at higher rpm for longer periods of time.

Using certain gears that work in conjunction with each other, the car gradually picks up speed as it shifts to higher gears. When the car shifts into higher gears, the rpm decreases, which reduces the load on the engine. The various gears are represented by gear ratio (which is the ratio of gears in both size and number of teeth). The smaller gears spin faster than the larger gears, and each gear position (first through six in some cases) uses different gears of different sizes and numbers of teeth to achieve smooth acceleration.

A transmission cooler is essential when transporting heavy loads because a heavy load puts additional stress on the engine, causing it to run hotter and burning transmission fluid. The transmission cooler is located inside the radiator where it removes heat from the transmission fluid. Fluid travels through tubes in the cooler to coolant in the radiator so the transmission stays cool and can handle higher loads.

What does a torque converter do

The torque converter multiplies and transmits the torque generated by the vehicle's engine and transmits it through gears in the transmission to the drive wheels at the end of the drive shaft. Some torque converters also act as a locking mechanism, linking the engine and transmission when running at the same speeds. This helps prevent transmission slippage resulting in loss of efficiency.

The torque converter can take one of two forms. The first, the fluid coupling, uses at least a two-piece drive to transfer torque from the transmission to the drive shaft, but does not increase torque. A hydraulic clutch, used as an alternative to a mechanical clutch, transfers engine torque to the wheels via a driveshaft. The other, the torque converter, uses at least three elements in total, and sometimes more, to increase the torque output from the transmission. The converter uses a series of vanes and a reactor or stator vanes to increase torque, resulting in more power. The stator or static vanes serve to redirect the transmission fluid before it reaches the pump, greatly improving the efficiency of the converter.

The inner workings of the planetary gear

Knowing how the parts of an automatic transmission work together can really put it all into perspective. If you look inside an automatic transmission, in addition to various belts, plates and a gear pump, the planetary gear is the main component. This gear consists of sun gear, planetary gear, planetary carrier and ring gear. A planetary gear roughly the size of a cantaloupe creates the various gear ratios needed by the transmission to achieve the necessary speeds to move forward while driving, as well as engage reverse.

The different types of gears work together, acting as input or output for the specific gear ratio required at any given time. In some cases, the gears are useless in a certain ratio and therefore remain stationary, with bands inside the transmission holding them out of the way until they are needed. Another type of gear train, the composite planetary gear, includes two sets of sun and planetary gears, albeit only one ring gear. The purpose of this type of gear train is to provide torque in a smaller space, or to increase the overall power of the vehicle, such as in a heavy duty truck.

The study of gears

While the engine is running, the transmission responds to whatever gear the driver is currently in. In Park or Neutral, the transmission does not engage because vehicles do not require torque when the vehicle is not in motion. Most vehicles have different drive gears that are useful when moving forward, from first to fourth gear.

Performance cars tend to have even more gears, up to six, depending on the make and model. The lower the gear, the lower the speed. Some vehicles, especially medium and heavy trucks, use overdrive to help maintain higher speeds and also provide better fuel economy.

Finally, cars use reverse gear to drive in reverse. In reverse gear, one of the smaller gears engages with the larger planetary gear, rather than vice versa when moving forward.

How the gearbox uses clutches and bands

In addition, the automatic transmission uses clutches and belts to help it reach the various gear ratios needed, including overdrive. The clutches come into action when the parts of the planetary gears are connected to each other, and the bands help to keep the gears stationary so that they do not rotate unnecessarily. The bands, driven by hydraulic pistons inside the transmission, fix parts of the gear train. The hydraulic cylinders and pistons also actuate the clutches, forcing them to engage the gears required for a given gear ratio and speed.

The clutch discs are inside the clutch drum in the transmission and alternate with steel discs in between. Clutch discs in the form of discs bite into steel plates due to the use of a special coating. Instead of damaging the plates, the discs gradually compress them, slowly applying force that is then transferred to the vehicle's drive wheels.

Clutch discs and steel plates are a common area where slippage occurs. Eventually, this slippage causes metal chips to enter the rest of the transmission and eventually cause the transmission to fail. A mechanic will check the transmission if the car is having problems with transmission slippage.

Hydraulic pumps, valves and regulator

But where does the "real" power come from in an automatic transmission? The real power lies in the hydraulics built into the transmission housing, including the pump, various valves and the regulator. The pump draws transmission fluid from a sump located at the bottom of the transmission and delivers it to the hydraulic system to actuate the clutches and bands contained therein. In addition, the inner gear of the pump is connected to the outer casing of the torque converter. This allows it to spin at the same speed as the car's engine. The outer gear of the pump rotates in accordance with the inner gear, allowing the pump to draw liquid from the sump on one side and feed it to the hydraulic system on the other side.

The governor adjusts the transmission by telling it the speed of the vehicle. The regulator, which contains a spring-loaded valve, opens more the faster the vehicle is moving. This allows the transmission hydraulics to pass more fluid at higher speeds. An automatic transmission uses one of two types of devices, a manual valve or a vacuum modulator, to determine how hard the engine is running, increasing pressure as needed and disabling certain gears depending on the ratio being used.

With proper maintenance of the transmission, vehicle owners can expect it to last the lifetime of the vehicle. A very robust system, an automatic transmission uses many different parts, including a torque converter, planetary gears, and a clutch drum, to provide power to the vehicle's drive wheels, keeping it at the desired speed.

If you have problems with the automatic transmission, have a mechanic help maintain the fluid level, inspect it for damage, and repair or replace it if necessary.

Common Problems and Symptoms of Automatic Transmission Problems

Some of the more common problems associated with a faulty transmission include:

- Lack of response or hesitation when shifting into gear. This usually indicates slippage inside the gearbox.

- The gearbox makes various strange noises, clanks and hums. Have a mechanic check your car when it makes these noises to determine what the problem is.

- A fluid leak indicates a more serious problem and the mechanic should fix the problem as soon as possible. Transmission fluid does not burn out like engine oil. Having the fluid level checked regularly by a mechanic can help resolve a potential problem before it occurs.

- A burning smell, especially from the transmission area, may indicate a very low fluid level. Transmission fluid protects gears and transmission parts from overheating.

- The Check Engine light may also indicate a problem with the automatic transmission. Have a mechanic run diagnostics to find the exact problem.