How does a torque converter work?

Content

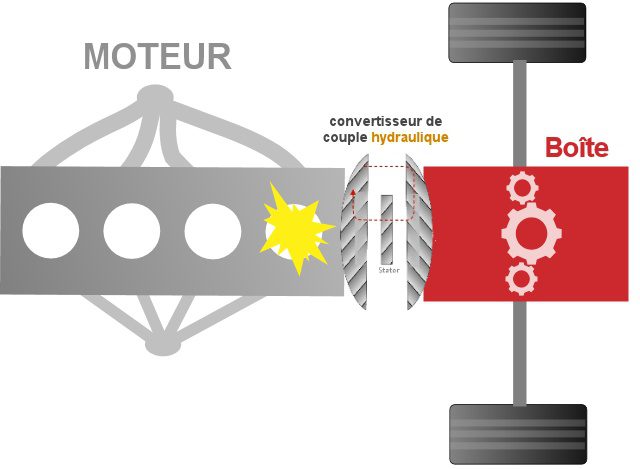

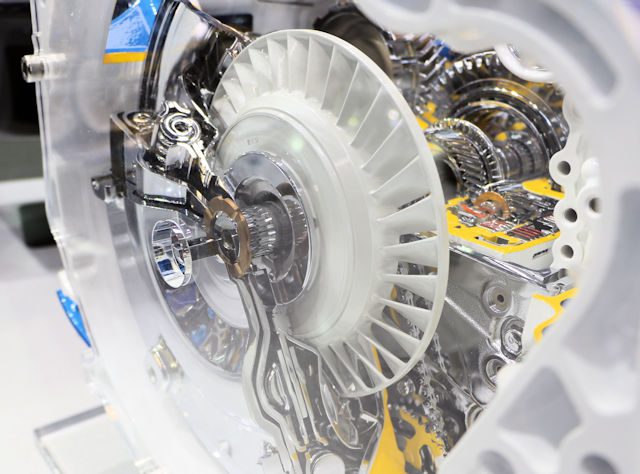

This component, called a torque converter or torque converter, is installed in automatic transmissions as a clutch. Hence, it represents the connection between the engine and the wheels (or rather the gearbox that is inserted between them).

Equips automatic transmissions that can be characterized as conventional (with planetary gears), as opposed to robotic transmissions (single or double clutch, same with parallel gears). CVTs also primarily use a converter, since the car must be able to stop without stopping the engine and therefore stall.

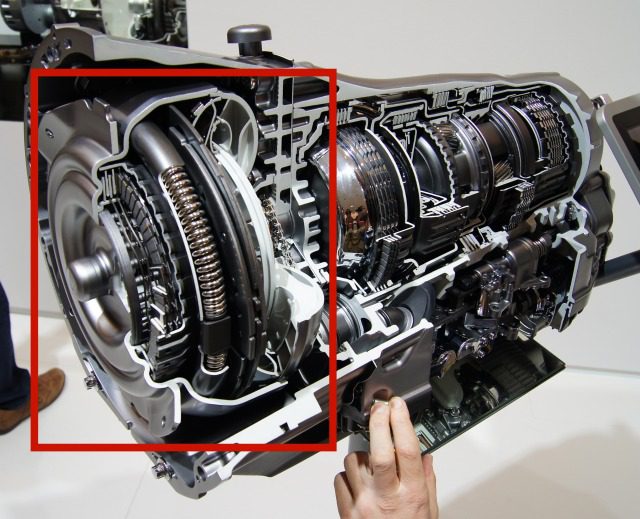

The location and shape of the elements can vary widely from one transducer to the next.

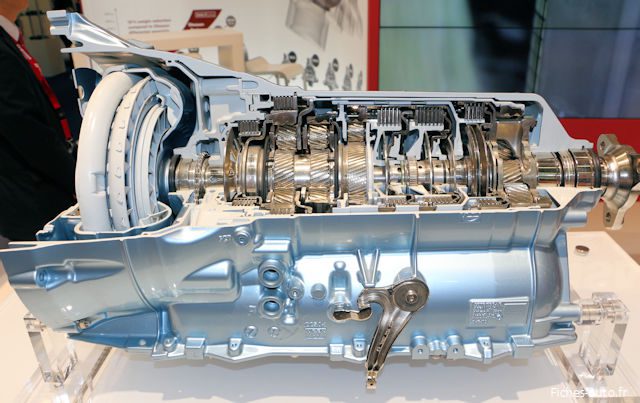

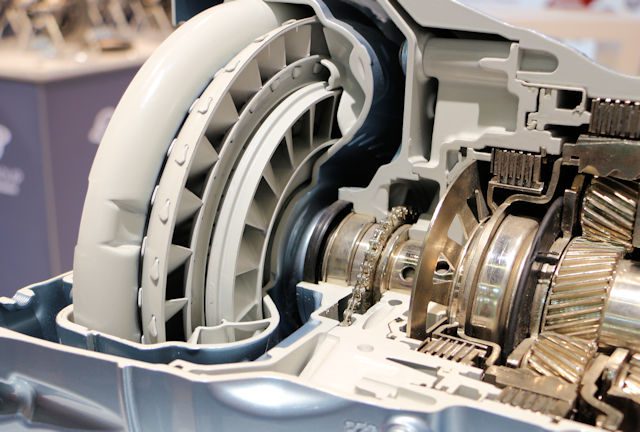

Here is a Mercedes' 9-speed longitudinal gearbox. The converter is on the left in red, and the gears and clutches of the gearbox on the right.

The basic principle

If a conventional clutch allows you to associate / correlate the rotation of the engine shaft with the rotation of the gearbox (and therefore the wheels) using the friction of the disk (clutch) against the flywheel, in the case of torque, the converter is the oil that will take care of this ... There is no more physical friction between two elements.

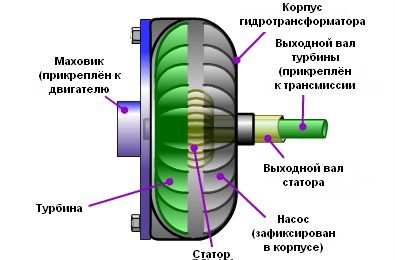

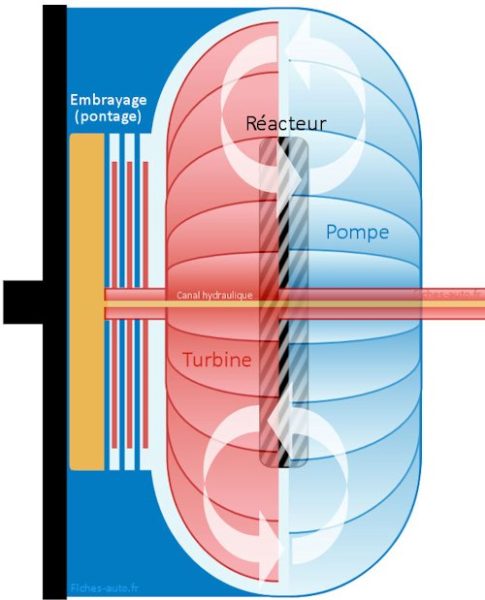

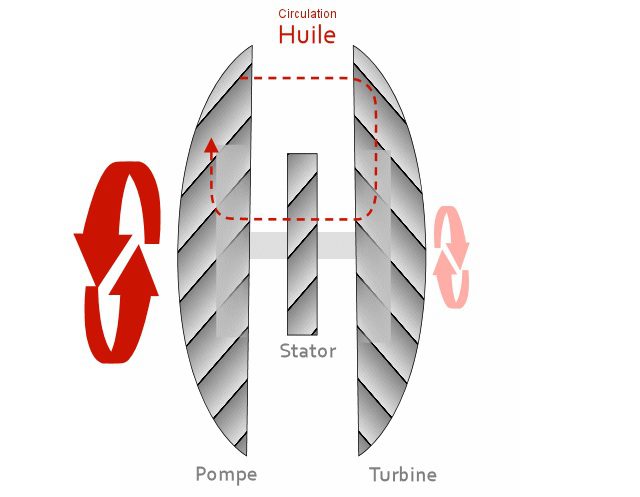

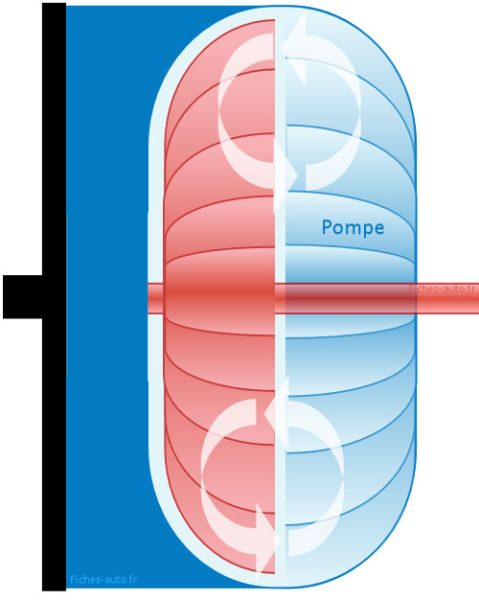

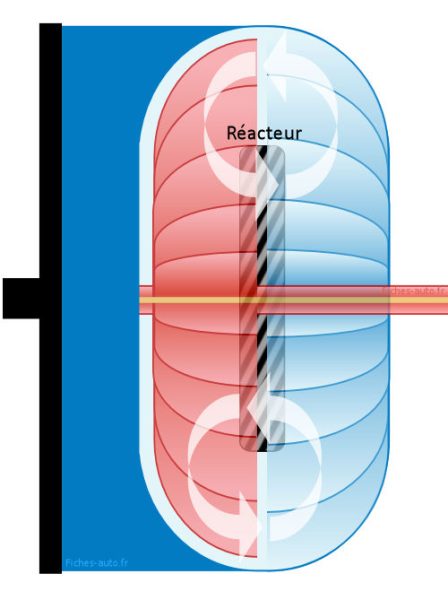

The red arrow shows the path traveled by the oil. It moves from one turbine to another in a closed cycle. The stator in the middle ensures optimum unit performance. The pump is driven by the engine, and the turbine is driven by the oil flow, itself driven by the pump, the circuit is closed. If we were to draw an analogy, we could compare a system with two fans installed face to face. By rotating one of the two, the generated wind will rotate the other in the opposite direction. The only difference is that the transducer does not move air, but oil.

To achieve this, the system uses hydraulic current as if it were wind (for your curiosity, know that the equations for liquids and gases are the same, both assimilate to liquids) and therefore work pretty close to that of a fan. ... Thus, instead of ventilating the air, we will ventilate the oil and restore the energy (hydrokinetic force) of the flow generated to rotate another "propeller". Because the system described here is filled with oil.

What about a hydrotransformer?

The hydraulic converter (thanks to the stator) allows more torque at the input to the gearbox than at the output of the engine.

Indeed, the transmitting pump (motor) spins faster than the receiving turbine (s) most of the time, which then results in the turbine benefiting from the higher torque (the power whose speed has been reduced provides higher torque). I invite you to read this article to familiarize yourself with the relationship between power and torque.

This phenomenon is all the more important because there is a difference in the rotational speed between the pump and the turbine. For example (numbers are taken at random), if the torque is 160 Nm at the crankshaft output at 2000 rpm, there could be 200 Nm at the gearbox input (hence the name "torque converter"). This is due to a kind of increase in oil pressure in the converter circuit (the stator causes a plug, see video at the bottom of the page). On the other hand, the torques are (almost) the same when the pump and turbine reach the same speed.

In short, all this suggests that the torque converter will provide more torque to the gearbox than the engine can provide (this is only when there is a significant delta between the turbine and pump rotations). A hollow engine will appear more powerful at low revs when coupled to the BVA (hence thanks to the converter, not the gearbox).

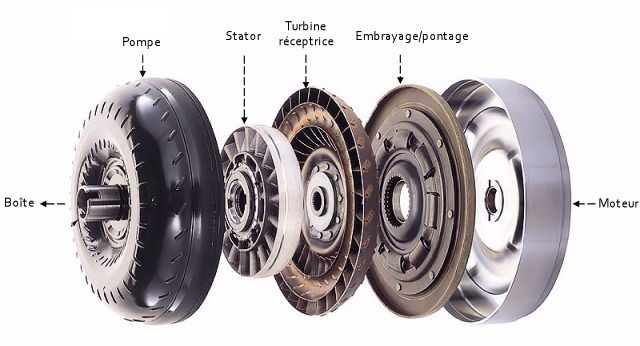

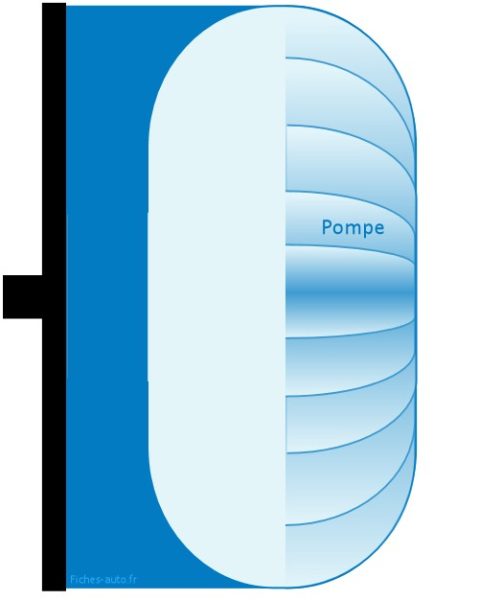

Pump and turbine

The engine shaft (crankshaft) is connected to a propeller (via a flywheel) called a pump. The latter mixes the oil thanks to the power of the engine, therefore it is called a pump (without the power of the engine that drives it, it becomes a simple turbine ...).

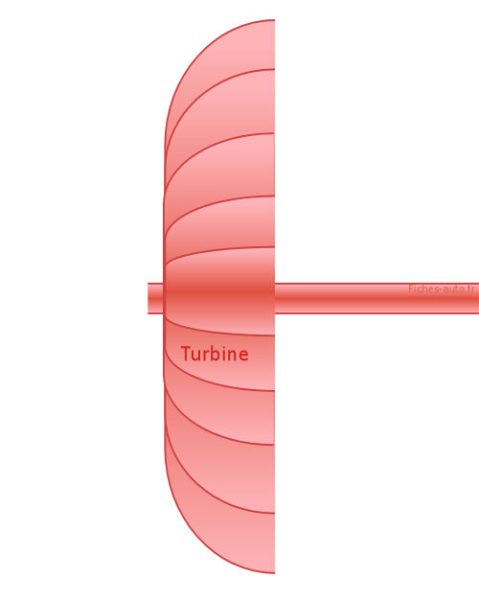

This pump pumps oil in the same direction as another turbine of a rather similar shape, but with inverted blades. This second turbine, connected to the gearbox, starts to rotate thanks to the force created by the oil flow: therefore, torque is transmitted between the engine and the gearbox (which itself is connected to the wheels via propeller shafts) using only oil. ! It works like a wind turbine: the wind is represented by the pump (turbine connected to the engine), and the wind turbine is the receiving turbine.

Thus, the sensation of slipping between gears (or when the vehicle is moving from rest) corresponds to the transfer of force through the fluid. Knowing that the faster the pump spins, the more the receiving turbine accelerates until it reaches the same speed as the pump.

The pump is connected to the motor

When I stop, there is a creep effect (automatic slow motion itself in Drive) because the pump continues to run (engine runs) and therefore transfers power to the receiving turbine. For the same reason, new cars have a Hold button, which allows you to cancel the rampage using the brakes (everything is controlled by a computer that brakes the wheels. When you are standing, it releases the brakes as soon as it receives a request from the accelerator pedal).

Keep in mind, however, that the torque converter allows the engine to stop without stopping because the pump can still continue to run even if the receiving turbine is stopped, then hydraulics "slip" occurs.

The turbine is connected to the gearbox

Also note that the pump is connected to a chain that drives the transmission oil pump, which then lubricates many of the gears that make up it.

stator

Also called a reactor, it is he who will act as a torque converter. Without the latter pair, pump + turbine qualifies only as a hydraulic coupling.

In fact, it is a smaller turbine than the other two, which is located exactly between the other two ... Its role is to reorient the oil flow to achieve the desired effect, so the circuit through which the oil flows is different. As a result, the torque transmitted to the input of the gearbox can be even higher than that of the engine. Indeed, this allows for a plugging effect that compresses the oil at a certain stage in the chain, which increases the flow force within the torque converter. But this effect depends on the speed of rotation of the turbine and pump.

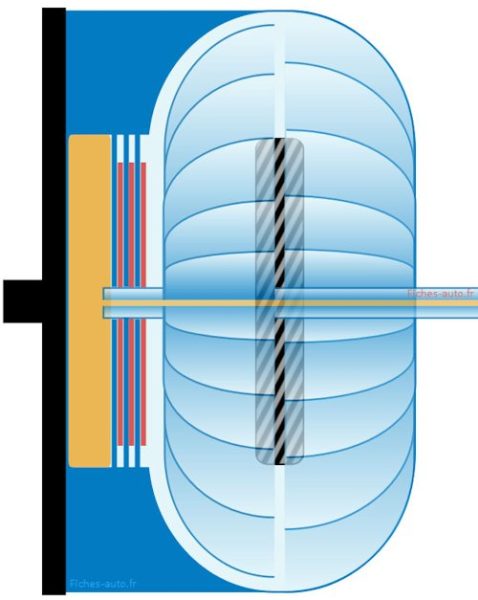

Axle / clutch

However, if the connection between the gearbox and the engine was carried out only by oil, the efficiency of everything would be low. Since there is a loss of energy between the two turbines due to slippage (the turbine never reaches the same speed as the pump), which therefore causes more consumption (if this were not a problem in the 70s in the USA, a completely different thing today).

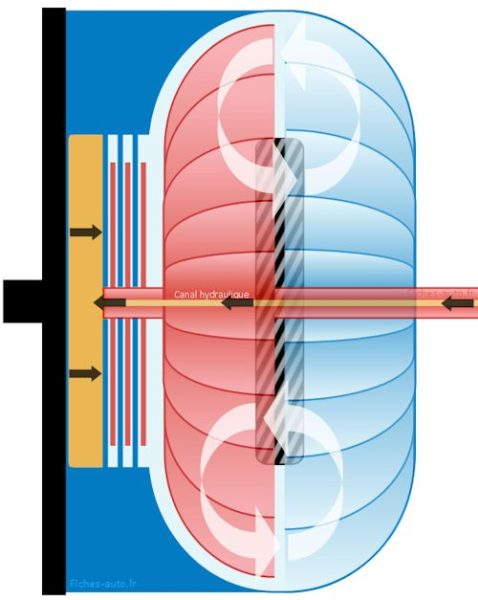

To overcome this, there is a clutch (simple and dry, or wet multi-disc, the principle is the same) that solidifies when the pump rotates at almost the same speed as the receiving turbine (this is called a bypass clutch). ). Thus, it allows for a secure mooring (but also with minimal flexibility to avoid breakage, as on any clutch, thanks to the springs that you can also see on the 9-speed gearbox pictured at the start of the season. ”Article). Thanks to this, we can obtain an even more powerful engine brake.

Bypass clutch

Here we are in the phase of clamping the multi-disc with hydraulic pressure that pushes the discs against each other.

After the jumper is made, the turbine and pump become one and the same oil mixing between the two parts no longer occurs. The converter has become static and acts like a banal driveshaft ...

How does a torque converter work in an automatic transmission? Electric Vehicle & Hybrid Vehicle Repair⚡

Benefits?

A torque converter is known to last longer than a conventional friction clutch (however, wet multi-plate clutches are almost as durable as converters) while maintaining the rest of the mechanics (the entire traction chain).

Indeed, the smooth operation (by the way, very pleasant) suddenly retains the elements (whether at the level of the engine or chassis), while a manual or robotic gearbox brightens the whole thing a little. On a mileage of more than 100 km, the difference is really felt in the durability of the parts. In short, a good time to buy a used one. Not to mention, the system is protected from anyone who cannot change gears. Because with a manual transmission, it is enough for the owner to change gears incorrectly for more than 000 km to harm the mechanics, which is not the case with this type of hydraulic clutch (which is not controlled by the driver).

In addition, there is no wear clutch (the bypass experiences very little sliding stress, and when it is multi-disc, it is never released). This also provides good savings, even if it is also necessary to consider draining the converter from time to time (oil is usually used with the rest of the gearbox) (ideally every 60, but also 000).

Finally, the fact that torque conversion exists makes it easy to reduce reporting without seriously impacting approval. This is why there were many BVAs a few years ago.

Disadvantages?

The only drawback, as far as I know, has to do with the very sporty driving pleasure. There is really too much buffer between the motor and the rest of the traction chain.

That's why at Mercedes we gladly replaced the multi-disc converter on the 63 AMG (see Speedshift MCT). Much easier and without slipping (with good blocking, of course, it depends on the driving modes), it allows you to limit the inertia of the engine. Acceleration response times are also shorter.

We can also point out the fact that slightly older BVAs slip a little due to the gradual tightening of the multi-discs (there is a special multi-disc clutch in each report that allows planetary gears to be locked). The roller really has no connection with the torque converter (it does not slip until the moment of departure, that is, approximately from 0 to 3 km / h).

All comments and reactions

Dernier comment posted:

tomorrow (Date: 2021, 06:27:23)

Hello

could you please give me some examples of a reliable diesel car with

torque converter transmission (5- or 6-speed, no

4 speeds) with a budget of about 2500, please

merci

Il I. 1 reaction (s) to this comment:

- Administrator SITE ADMINISTRATOR (2021-06-29 11:32:05): Good old Golf 4 Tiptronic mated to 1.9 TDI 100 hp

(Your post will be visible under the comment after verification)

Comments continued (51 Ã 178) >> нажмите здесь

Write a comment

Which body do you like best?