How the oil pump works, device and malfunctions

Content

The lubrication system of an automobile engine is built on the principle of supplying liquid oil to all friction pairs of parts under pressure. After that, it again flows into the crankcase, from where it is taken for the next cycle of passage along the highways.

The oil pump is responsible for ensuring the circulation of oil and creating the necessary pressure in the system.

Where is the oil pump in a car

Most often, the pump is located in front of the engine, immediately behind the auxiliary drive pulleys, but sometimes below, under the crankshaft, in the upper part of the crankcase. In the first case, it is driven directly from the crankshaft, and in the second case, it is driven by a chain from its sprocket or gear transmission.

An oil intake is attached to the pump, the opening of which with a coarse filter is below the oil level in the crankcase, usually even in a specially made recess.

Varieties

In principle, all pumps are the same, their job is to capture oil in a certain cavity of a large volume, after which this cavity moves while decreasing.

Due to its incompressibility, the pumped liquid will be squeezed out into the outlet line, and the developed pressure will depend on the geometric dimensions, rotation speed, oil consumption and the operation of the control device.

The latter is most often a conventional spring-loaded pressure reducing valve that opens at a given pressure and dumps excess oil back into the crankcase.

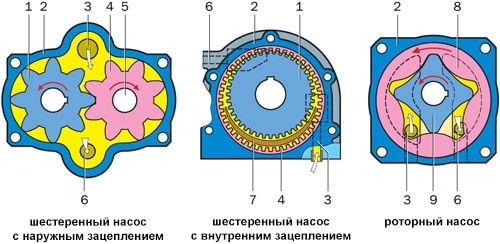

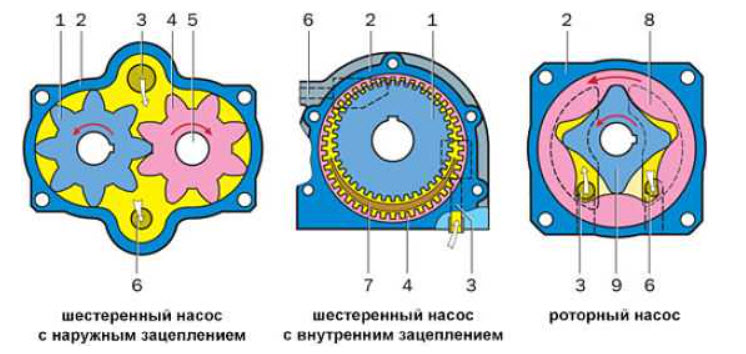

By design, automotive oil pumps can be of several types:

- gearwhen a pair of gears, rotating, moves oil in the cavities between its large teeth and the pump housing, synchronously supplying it from the inlet to the outlet;

- rotary type, here one of the gears with an external tooth is nested in another, with an internal tooth, while the axes of both have an offset, as a result of which the cavities between them change their volume from zero to a maximum in one revolution;

- plunger slide-type pumps are less common, since accuracy and minimum losses are not significant here, and the volume of equipment is larger, the wear resistance of plungers is also lower than that of a simple gear pair.

1 - main gear; 2 - body; 3 - oil supply channel; 4 - driven gear; 5 - axis; 6 - oil supply channel to engine parts; 7 - separating sector; 8 - driven rotor; 9 - main rotor.

The most commonly used pumps are rotary type, they are simple, compact and very reliable. On some machines, they are taken out into a common block with balancer shafts, simplifying the chain drive on the front wall of the engine.

Design and operation

The pump drive can be mechanical or electric. The latter is rarely used, usually it occurs in complex lubrication systems for sports engines with a dry sump, where several such units are installed at once.

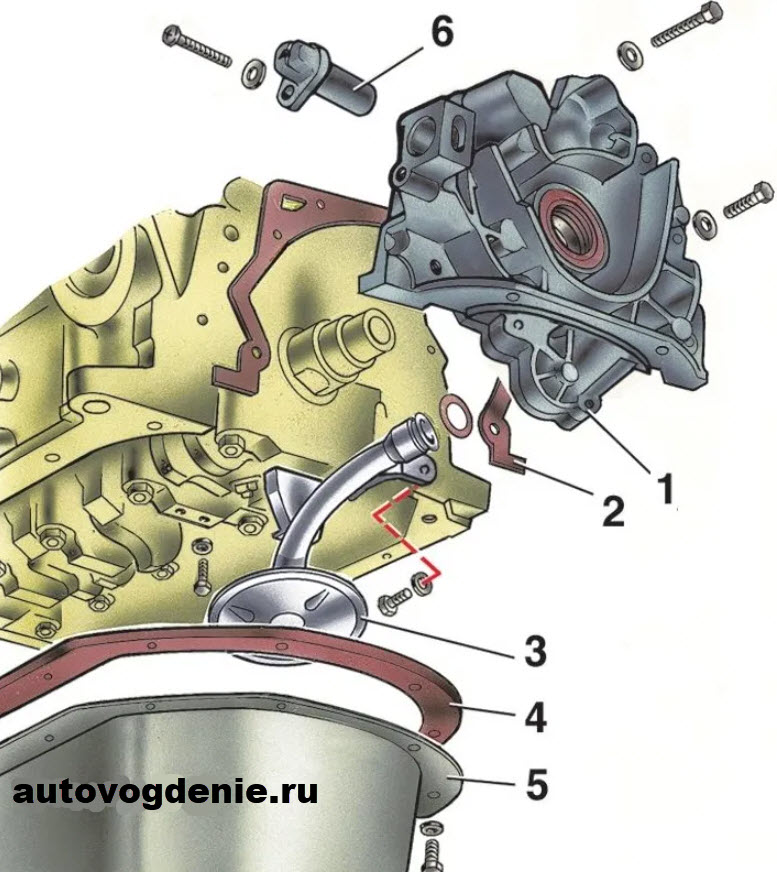

In other cases, the pump is purely mechanical and contains only a few parts:

- a housing, sometimes of a rather complex shape, since it is also an integral part of the crankcase, it contains a part of the oil intake, a seat for the front crankshaft oil seal, a position sensor and some fasteners;

- drive pinion;

- driven gear, driven by the drive;

- pressure reducing valve;

- oil intake with a coarse filter (mesh);

- sealing gaskets between the components of the housing and its attachment to the cylinder block.

1 - pump; 2 - gasket; 3 - oil receiver; 4 - pallet gasket; 5 - crankcase; 6 - crankshaft sensor.

The work uses the principle of continuous oil supply with a capacity determined by the speed of rotation of the crankshaft.

The gear ratio of the drive and the injection geometry are selected in such a way as to provide the minimum required pressure in the worst conditions, that is, with the thinnest hot oil and the maximum allowable flow through worn engine parts.

If the oil pressure still drops, this means that the gaps in the system are out of range, there is not enough performance, the engine needs a major overhaul. The corresponding red signal lights up on the indicator panel.

How to check the oil pump

The only parameter to be checked without dismantling is the oil pressure in the system. For operational control, some machines have a dial indicator and indicate the minimum allowable pressure at idle with hot oil. The control lamp sensor is set to the same threshold, this is an emergency indicator, therefore it has a red color.

The pressure can be measured with an external manometer, the fitting of which is screwed in instead of the sensor. If its readings do not correspond to the norm, then the engine will have to be disassembled in any case, due to general wear or malfunctions in the pump. On some cars, the drive can be cut off, but now this is extremely rare.

The removed pump is disassembled, and its condition is assessed in detail. Most often, wear of the teeth of the rotors and gears, axle play, broken holes in the housing, malfunctions of the pressure reducing valve, even its simple clogging are observed. If wear is noted, the pump assembly is replaced with a new one.

Malfunctions

The main problem in troubleshooting that caused pressure loss will be to separate the wear of the pump and the motor as a whole. There is almost never a loss caused by the pump alone. This can only happen after an illiterate overhaul, when a badly worn pump has not been replaced.

In other cases, the fault lies in the wear of the liners, shafts, turbine, regulators controlled by oil pressure, and defects in the injection lines. The engine is sent for repair, during which the oil pump is also replaced. It can be said that no specific malfunctions are currently observed.

An exception may be in the destruction of the drive and clogging of the valve and coarse screen. But it can be considered a breakdown of the pump only conditionally.

Prevention of malfunctions is to keep the lubrication system clean. The oil must be changed twice as often as the instructions provide, do not use cheap grades and counterfeit products, and in engines with an unknown past, prophylactically remove the oil pan and clean it of dirt and deposits by washing the oil receiver strainer.