How a modern engine works

Content

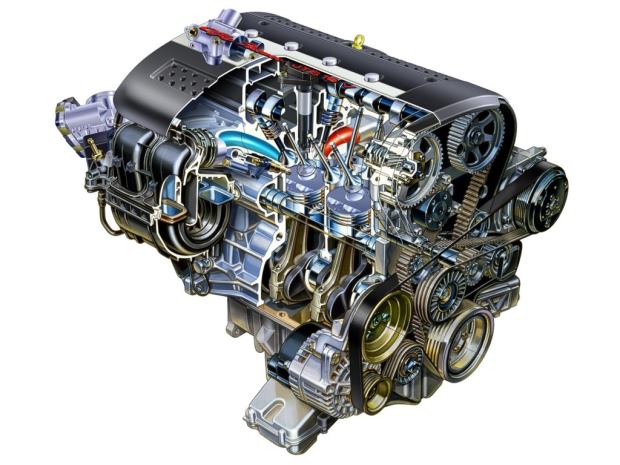

You turn the key in the ignition and the engine starts. You step on the gas and the car moves forward. You take out the key and the engine shuts off. That's how your engine works, right? It's a lot more detailed than most of us realize, with behind-the-scenes going on every second.

The inner workings of your engine

Your car's engine is made up of two main components: the cylinder block and the cylinder head.

The top of the engine is called the cylinder head. It contains valves that open and close to regulate the flow of air/fuel mixture and exhaust gases from the individual cylinders. There must be at least two valves per cylinder: one for intake (release of unburned air-fuel mixture into the cylinder) and one for exhaust (release of spent air-fuel mixture from the engine). Many engines use multiple valves for both intake and exhaust.

The camshaft is attached either through the middle or on top of the cylinder head to control valve operation. The camshaft has projections called lobes that force the valves to open and close precisely.

The camshaft and crankshaft are closely related. They must run at the perfect time for the engine to run at all. They are connected by a chain or timing belt to maintain this timing. The camshaft must complete two complete revolutions for every revolution of the crankshaft. One complete revolution of the crankshaft is equal to two strokes of the piston in its cylinder. The power cycle—the process that actually produces the power you need to move your car—requires four piston strokes. Let's take a closer look at how a piston works inside an engine and the four different stages:

Consumption: To begin a duty cycle, the first thing an engine needs is an air-fuel mixture that enters the cylinder. The intake valve opens in the cylinder head when the piston starts to move down. The fuel-air mixture enters the cylinder at a ratio of approximately 15:1. When the piston reaches the bottom of its stroke, the intake valve closes and seals the cylinder.

compression: The piston moves up in the cylinder, compressing the air/fuel mixture. Piston rings seal the sides of the piston in the cylinder, preventing loss of compression. When the piston reaches the top of this stroke, the contents of the cylinder are under extreme pressure. Normal compression is between 8:1 and 10:1. This means that the mixture in the cylinder is compressed to about a tenth of its original uncompressed volume.

Power supply: When the contents of the cylinder are compressed, the spark plug ignites the air-fuel mixture. There is a controlled explosion that pushes the piston down. It's called power stroke because it's the force that turns the crankshaft.

Exhaust: When the piston is at the bottom of its stroke, the exhaust valve in the cylinder head opens. When the piston moves up again (under the influence of simultaneous power cycles occurring in other cylinders), the burnt gases in the cylinder are pushed up and out of the engine through the exhaust valve. When the piston reaches the top of this stroke, the exhaust valve closes and the cycle begins again.

Consider it: If your engine is idling at 700 RPM or RPM, that means the crankshaft is fully rotating 700 times per minute. Since the duty cycle occurs every second revolution, each cylinder has 350 explosions in its cylinder every minute at idle.

How is the engine lubricated?

Oil is an important fluid in engine operation. There are small passages in the internal components of the engine, called oil passages, through which oil is forced. The oil pump draws engine oil from the oil pan and forces it to circulate through the engine, ensuring smooth operation of densely packed metal engine components. This process does more than just lubricate the components. It prevents friction that causes excess heat, cools internal engine parts, and creates a tight seal between engine parts, such as between cylinder walls and pistons.

How is the fuel-air mixture formed?

Air is sucked into the engine due to the vacuum created during engine operation. As air enters the engine, the fuel injector sprays fuel that mixes with the air at a ratio of approximately 14.7:1. This mixture is sucked into the engine during each intake cycle.

This explains the basic inner workings of a modern engine. Dozens of sensors, modules, and other systems and components work during this process, allowing the engine to run. The vast majority of cars on the road have engines that work the same way. When you consider the precision required to keep hundreds of engine components running smoothly, efficiently and reliably over thousands of miles over many years of service, you begin to appreciate the work of engineers and mechanics to get you where you need to be. go.