How drum brakes work

Content

Some vehicles use a braking system that is partially composed of drum brakes. They are so called because they use friction applied to metal drums attached to the wheels to slow down and stop the car. While disc brakes provide better braking performance and have become more common on modern vehicles, drum brakes are still used in certain applications. Drum brakes are sometimes found on the rear wheels of entry-level cars for cost savings, as well as in classic cars.

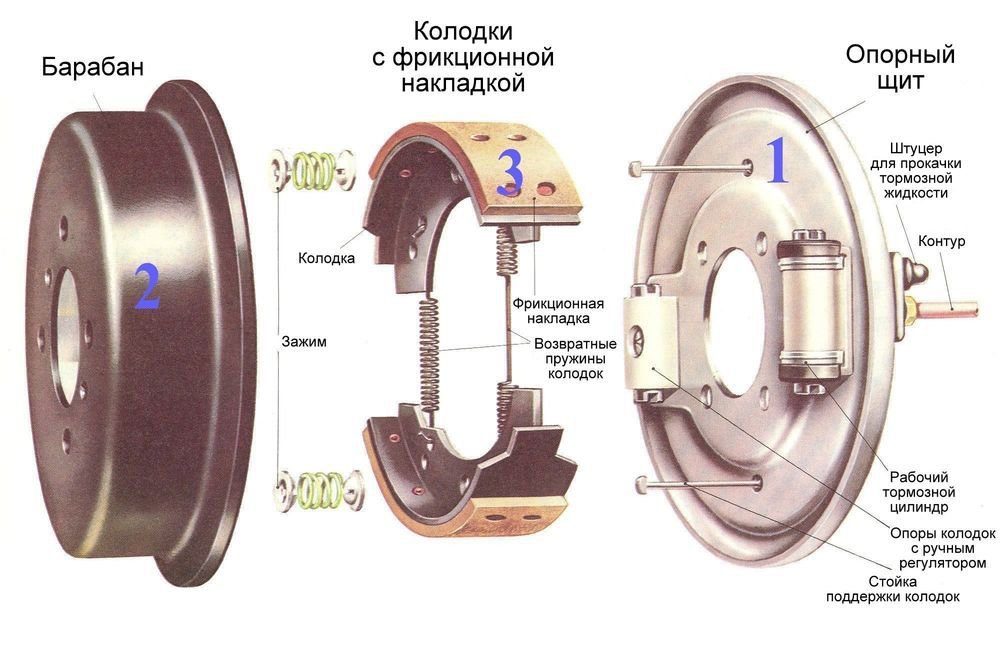

Parts that make up a drum brake system

Substrate: Provides a solid base for other drum brake components. Attaches to axle hub.

brake drum: Bolted to the wheel hub and rotates with the wheel. Often made of cast iron and resistant to heat and wear. This is what you see when you look at an assembled drum brake, and is the component that brake force is applied to to slow or stop the vehicle.

wheel cylinder: Contains two pistons, one at each end of the cylinder, to actuate the brake pads. The cylinder applies pressure to the pistons, which press the brake pads against the drum, slowing or stopping the vehicle. One cylinder is needed per wheel.

Brake shoe: Pressed into the drum to create the friction needed to slow or stop the vehicle. Attaches to a support, but can slide when pressure is applied from the wheel cylinder. It has a lining attached to it, consisting of organic or metallic compounds. The liner is what actually makes contact with the drum and wears out with use. Each brake contains two pads. The primary pad is closer to the front of the car, and the secondary pad is closer to the back. Brake pads may be interchangeable depending on the type and brand.

Automatic regulator: keeps the brake pads at a constant distance from the drum, even when the lining wears out.

Return springs: Pulls the brake pads away from the drum when the driver releases the brake pedal.

How drum brakes work

Brakes should respond instantly. When the driver presses the pedal, a piston inside the brake master cylinder pressurizes the hydraulic fluid into the brake lines, which then pressurizes the wheel cylinder and pushes the pads into the drum. The harder the driver presses on the pedal, the more pressure will be inside the brake lines and the more the pads will press on the drum. The distance the pads travel is small, and the return springs must pull them away from the drum as soon as the rider releases the pedal.

Emergency drum brakes

Some cars have disc brakes on all four wheels but still use a small drum brake located inside the wheel hub assembly as an emergency (or parking) brake. When the emergency brake is applied, a lever attached to the cable pushes the pads apart. This provides direct control, rather than through a wheel cylinder or brake hydraulics, allowing the car to stop even if the conventional brakes fail.

Drum brake wear

The brake drum and pads should be the only components of the drum brake system that need to be replaced. Shoe lining wears out with use and generally new shoes need to be installed every 35,000 miles, although this depends on your particular vehicle and driving style. Brake drums can last over 100,000 miles, but they usually need to be replaced in pairs. Otherwise, the wheel cylinder, auto adjuster, and return springs should last the lifetime of your vehicle, although mechanical problems or damage from debris or an accident is possible. However, it's best to check your brake fluid every 24,000 to 36,000 miles and immediately if you suspect a leak.

Symptoms of drum brake problems

There are several signs that alert the driver to problems with drum brakes.

Noise from the brakes: Since the lining of a shoe wears out with use, excessive or unusual noises may indicate that the lining is omitted or missing. A technician can check why your brakes are noisy, but changing the brake pads often fixes the problem.

Jitter or Pedal PulsationA: If the brake pedal pulsates or shakes when you press it, your drums are most likely warped. Brake drums must be perfectly round, and deformation can occur due to overuse or overheating. Typically, replacing the drums will fix the problem and restore normal braking.

Spongy or low brake pedal: The brake pedal should feel good, and the braking force should match how hard you press the pedal. If the pedal feels spongy or lower than normal, this is often a sign of contaminated brake fluid or a leak in the system. The presence of air or water in the fluid reduces its effectiveness, and leakage is a serious problem. Have a mechanic flush the fluid or check the system for leaks to restore full braking power. A bad wheel cylinder can also be the cause of a soft or low brake pedal.

Brakes are arguably the most important safety system in a car, so keep an eye out for any unusual symptoms that may indicate a part in your drum brake system needs to be replaced.