How to make a spoiler for a car yourself: tips for making and installing

Content

To make a spoiler for a car yourself, you do not need special tools or expensive materials, but when tuning a car with your own hands, it is important to know when to stop. If you go too far with the size of the element, then the car will look ridiculous, and driving such a car will be unsafe due to impaired aerodynamics.

A homemade spoiler on a car is placed on the trunk to press the back of the car to the road, improving grip, acceleration and handling. A hand-made part costs about half the price of a factory one.

Variants of homemade fairings for cars

There are two types of air deflectors mounted on the rear rack, which differ in shape and aerodynamic characteristics:

- The spoiler pressurizes the air flow above the car and cuts it under the bottom, improving the aerodynamics of the car, its acceleration and traction.

- The wing, like the spoiler, serves to increase the downforce of the car, its main difference is the presence of a gap between the part itself and the surface of the car trunk. Due to the free space, the wing is flown by air from both sides and is not able to increase the dynamics of the acceleration of the car.

Homemade spoiler

Materials of manufacture

The main properties for a spoiler are its shape and aerodynamic characteristics, the material of manufacture is not significant. You can make it yourself from the following materials:

- gypsum;

- Particleboard;

- mounting foam;

- foam and fiberglass;

- galvanized iron.

When planning what you can make a spoiler for a car from, it is better to choose the material that is easier for you to work with.

Form

All fairings can be divided into two types:

- factory - created by car manufacturers;

- individual - made to order in a tuning studio or with your own hands.

The aerodynamic characteristics of spoilers are fundamentally important only for sports cars, because they begin to show their properties only at speeds above 180 km / h. Regular drivers often install fairings to give the car smoother lines and a stylish look.

The aerodynamic characteristics of spoilers are fundamentally important only for sports cars, because they begin to show their properties only at speeds above 180 km / h. Regular drivers often install fairings to give the car smoother lines and a stylish look.

Making a spoiler with your own hands

Before you make a fairing, you need to carefully consider its appearance, design and location, as well as roughly calculate the weight - an incorrectly made or installed spoiler can degrade the performance of the car.

Necessary tools and materials

To make a homemade spoiler for a car from foam and iron, you need:

- galvanized iron sheet with a thickness of 1,5 mm or more;

- scissors (ordinary and for metal);

- Painting tape;

- a large piece of cardboard (you can use packaging from household appliances);

- felt-tip pen;

- Styrofoam;

- large stationery knife;

- hacksaw;

- glue;

- tracing paper or plain paper to create a drawing;

- Sander;

- sandpaper;

- fiberglass fabric;

- gelcoat is a ready-made material for the protective coating of composites;

- degreaser;

- polyester resin composition;

- primer;

- auto enamel;

- varnish.

Spoiler drawing

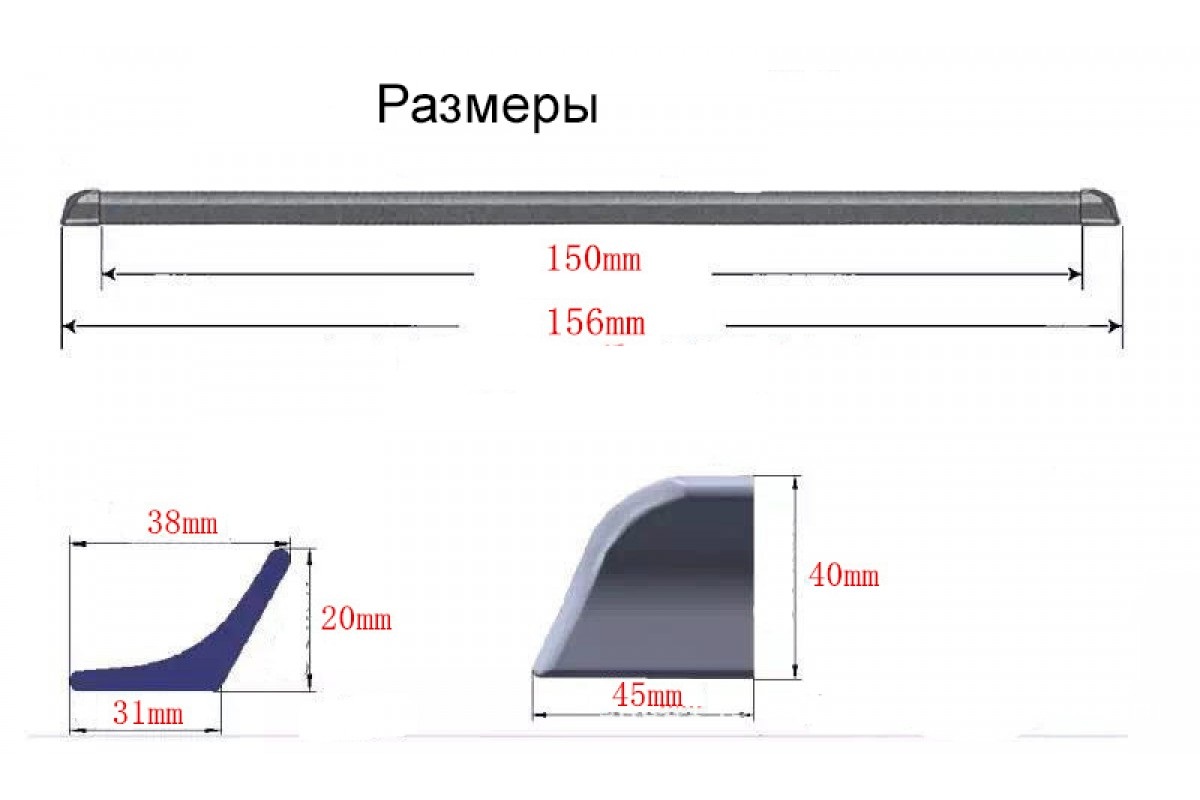

The first step in creating a spoiler is to create a blueprint. The design of the part must be verified to the millimeter so as not to spoil the aerodynamics of the car.

Spoiler drawing

To make a template:

- Measure the width of the rear trunk of the car.

- They are precisely determined with the size, height and shape of the fairing (you can see photos of well-tuned cars of a similar brand).

- They make a drawing of a spoiler on a car, taking into account the dimensions of the car and the place where the part is attached.

- Transfer the drawing to cardboard and cut it out.

- They try on the workpiece on the machine. If the appearance and characteristics of the resulting element are completely satisfied, then go directly to the manufacturing process.

Manufacturing process

Further manufacturing steps:

- Attach a cardboard template to a sheet of iron and circle.

- A sample is taken and parts are cut out with metal scissors.

- Styrofoam increases the volume on the spoiler: cut out individual elements of the fairing with a clerical knife and glue them to the metal part.

- They try on an iron blank on the trunk and check its level and symmetry.

- If necessary, correct the shape of the future fairing with a clerical knife or build up even small pieces of foam.

- Cover the foam with a gel coat.

- Paste the workpiece with several layers of fiberglass cloth, making sure that there are no air bubbles between them. Each subsequent layer should be stronger and denser than the bottom.

- Cover the surface of the reinforced workpiece with polyester resin and leave to dry.

- Grind and prime the resulting part.

- After drying, the primers are applied to the spoiler with automotive enamel and varnish.

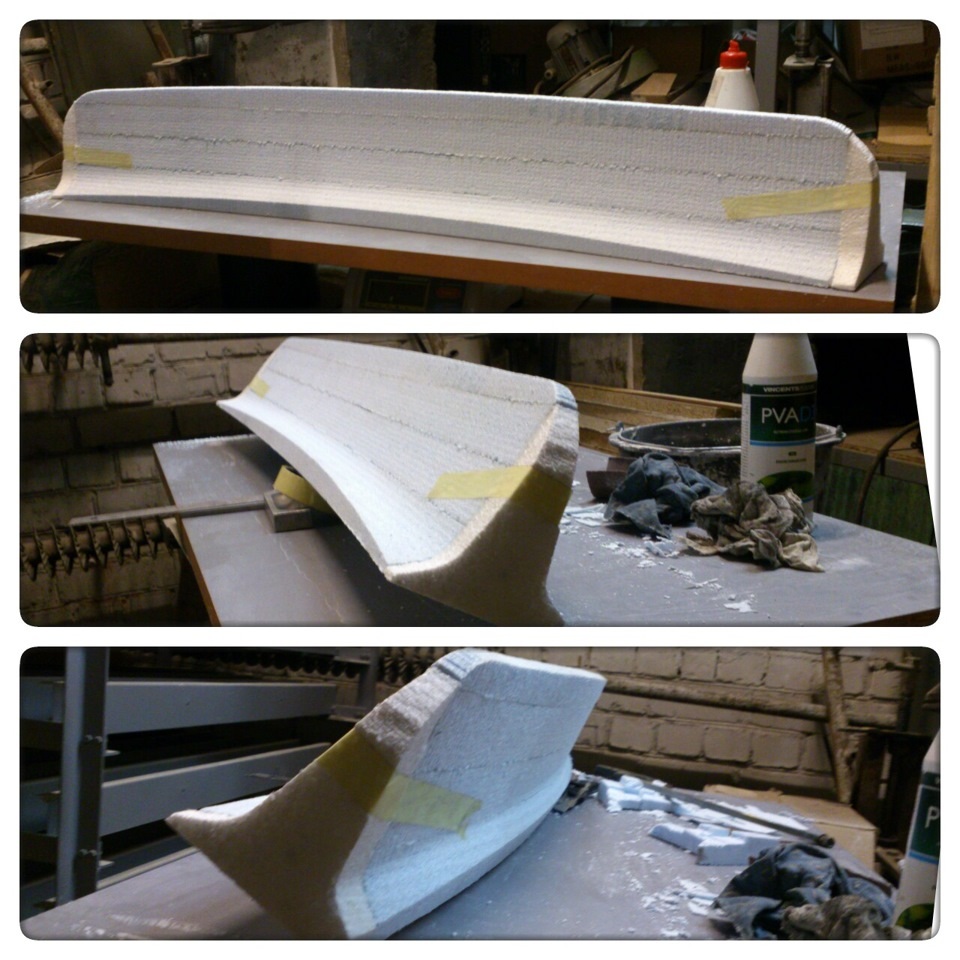

Spoiler making

Car mount

A homemade spoiler on a car can be attached in different ways:

On double sided tape

The easiest way, but also the least reliable, it is also not suitable for installing large or heavy fairings. Description of works:

- In order for the part to “grab” well, work on its fastening is carried out at a temperature above + 10-15 degrees. If it is colder outside, drive the car into a heated box or garage and let it warm up for several hours before and after installation.

- Thoroughly wash, degrease and dry the rear trunk of the car, paying special attention to the attachment points of the new element. Additionally, you can treat the surface with an adhesion activator.

- The protective tape is peeled off gradually, over several centimeters, periodically checking the accuracy of the spoiler installation on the body and ironing the stuck part. The most reliable contact of double-sided tape is the first. If the part has been peeled off several times, then it will no longer be possible to firmly install it, it is best to replace the adhesive tape or stick the fairing with a sealant.

- Fix the installed spoiler on the trunk with masking tape and leave to dry for a day (in extreme cases - for a couple of hours).

At pressure washers, workers should be warned that some parts of the vehicle are covered with double-sided tape.

For sealant

When used properly, caulk is stronger than tape. To install a spoiler with it, you need:

- Accurately mark the part attachment area on the body with a water-soluble marker.

- Degrease, wash and dry the surface.

- Depending on the type of sealant, it may be necessary to additionally apply the base.

- Apply a thin layer of sealant on the trunk or on the part to be glued (it makes no sense to smear both surfaces).

- Attach the spoiler to the desired place, without pressing down, and check the accuracy and symmetry of its location, carefully adjusting it if necessary.

- Push the fairing with a dry cloth.

- It is best to remove excess sealant with two types of cloth napkins: wet, and after it - impregnated with a degreaser.

Spoiler mounting on sealant

For self-tapping screws

The strongest and most reliable mount, but requiring a violation of the integrity of the rear trunk. Step-by-step instruction:

- First, protect the paintwork in the work area with masking tape.

- Transfer the attachment points to the trunk. To do this, you need to attach a sheet of thin paper to the junctions of the spoiler, mark the fasteners on it and transfer the marks to the car using the resulting template.

- Try on the part to check and drill holes.

- Treat the holes with an anti-corrosion agent.

- For better coupling of the fairing with the body, you can additionally use glue, silicone or pieces of double-sided tape.

- Attach the part to the car.

- Clean the surface from the remnants of adhesive tape.

The most popular types of spoilers

All spoilers can be divided into two types:

- decorative - small pads on the rear contour of the trunk, they have little effect on the dynamics, but give the car a more elegant silhouette;

- functional - high sport-style spoilers that really change the airflow pressure at high speed and the downforce of the car.

The spoiler does not have to be done entirely by hand. If you like the store parts, but do not fit the width of the trunk, you can buy a ready-made one, saw it and build it up with an insert (or cut it) to the desired size.

To make a spoiler for a car yourself, you do not need special tools or expensive materials, but when tuning a car with your own hands, it is important to know when to stop. If you go too far with the size of the element, then the car will look ridiculous, and driving such a car will be unsafe due to impaired aerodynamics.