How to repair the power steering pump yourself

Content

- liquid level diagnostics and air lock pumping

- Signs of power steering failure and their possible causes

- Reducing the level of the working fluid:

- Extraneous sounds, whistling while turning the steering wheel with the engine running:

- At idle or at low speed, significant force is required to turn the steering wheel:

- When the drive belt is removed, longitudinal or transverse play of the pump shaft is felt:

- Vibrations or shocks when turning the steering wheel while driving:

- Power steering pump requires special attention

- Preparation for pump repair

- Pump disassembly, troubleshooting

- Leakage due to damaged hoses, seals or gaskets.

- the drive belt is loose or worn;

- worn bearings or pump shaft;

- clogged valves;

- frozen liquid.

- faulty power steering pump;

- clogged hydraulic system;

- low fluid level.

- pump bearing needs to be replaced.

- the drive belt is loose or worn;

- faulty power steering pump;

- faulty control valve;

- low fluid level;

- air in the system.

- Most often, the bearing fails, so be sure to stock up on a new one. It usually has an outer diameter of 35 mm and is marked 6202, although other options are possible.

- Two rubber o-rings, an oil seal, a gasket and two copper washers. All this can be replaced with a repair kit for the power steering pump, which can be found in the car shop.

- Thinner white spirit or WD-40.

- Cleaning cloth.

- Sandpaper from P1000 to P2000. It can take quite a lot if there is a need for grinding.

- A large syringe and a container for pumping oil from the tank.

- wrenches and heads for 12, 14, 16 and 24;

- circlip puller;

- a hammer;

- screwdrivers;

- superfiles;

- electric drill and drill bit 12 mm or larger.

Power steering (GUR) is part of the steering mechanism and is available on almost every modern car. The power steering allows you to significantly reduce the physical effort required to turn the steering wheel, and also improves the maneuverability and stability of the car on the road. If the hydraulic system fails, steering control is retained but becomes tighter.

The system as a whole is quite reliable and rarely causes trouble for car owners. It is only necessary to monitor the oil level in the storage tank and, in case of a noticeable decrease, diagnose the tightness of the system, find and eliminate leaks, especially at the points where the pipes are connected to the fittings.

Regular replacement of dirty and exhausted working fluid will significantly extend the life of the hydraulic booster. This should be done at least once every two years.

You should also pay attention to the condition of the pump drive belt. It happens that it is required to adjust or tighten it, and in case of wear, replace it. To tighten or remove the belt, you usually need to loosen the fixing bolt and move the pump housing in the desired direction.

liquid level diagnostics and air lock pumping

The liquid level changes with temperature. To warm it up to about 80 ° C, at idle speed of the internal combustion engine, turn the steering wheel a set of times from one extreme position to another. This will also help remove air pockets from the hydraulic system.

Do not hold the steering wheel in the extreme position for more than five seconds, so that the liquid does not boil and damage the pump or other power steering components. then stop the internal combustion engine and diagnose the level of the working fluid.

If there is air left in the system, it will compress when the engine is running. This will cause the liquid level to drop. Therefore, once again diagnose the level in the tank with the engine running to make sure there is no difference.

Add liquid if necessary.

This simple procedure in many cases will solve problems with the power steering. Otherwise, additional diagnostics will be required.

Signs of power steering failure and their possible causes

Reducing the level of the working fluid:

Extraneous sounds, whistling while turning the steering wheel with the engine running:

At idle or at low speed, significant force is required to turn the steering wheel:

When the drive belt is removed, longitudinal or transverse play of the pump shaft is felt:

Vibrations or shocks when turning the steering wheel while driving:

Vibrations or shocks can also be caused by reasons not related to the power steering - incorrect wheel balancing, suspension or steering failures. Accurate diagnostics of power steering is possible only on a special hydraulic stand.

Power steering pump requires special attention

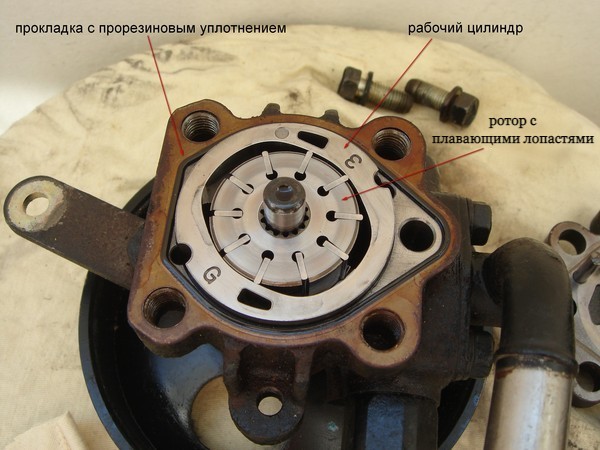

The most critical and vulnerable element of the power steering is the pump, which is driven by the car engine and pumps the working fluid in a closed circuit. Usually it is a vane type pump, which is distinguished by quality and high performance.

The hydraulic pressure it creates can reach 150 bar. The pump rotor is rotated by a belt drive from the crankshaft. During operation, the pump is subjected to significant loads. It is he who most often becomes a source of problems in the operation of the steering mechanism and requires repair or replacement.

Pump failure can be caused by overheating, contamination of the hydraulic system, insufficient amount of working fluid or its non-compliance with requirements.

If you continue to drive with a faulty hydraulic steering pump, this can eventually lead to failure of other components of the power steering. Therefore, it is not worth delaying repair or replacement.

You can contact a car service, or you can save a decent amount of money and try to repair the pump yourself. It does not require sophisticated equipment or special qualifications. It is enough to have the desire, time and some experience in performing mechanical work, as well as attention and accuracy.

Preparation for pump repair

For self-disassembly and repair of the power steering pump, you will need certain tools, spare parts and materials.

Required Tools:

To avoid mistakes during reassembly, prepare a workspace with numbered pieces of paper. it is worth having a workbench with a vise.

Pump disassembly, troubleshooting

There may be some differences in the design of the pump for machines of different brands, but the basic steps for disassembly and repair are similar. First you need to pump out the oil from the system with a syringe. then disconnect the tubes and plug the outlet holes with a rag so that dirt does not get inside.

To remove the pump, you need to unscrew the bolt that secures it to the bracket, and the bolt of the drive belt tension adjustment system. Before dismantling, the removed pump must be washed with a solvent. Remove the back cover.

To do this, depending on the design, you need to unscrew 4 bolts or remove the retaining ring by knocking it out with a pin (you can use a nail) through the hole on the side. further, tapping the body with a hammer, we achieve that the spring inside squeezes out the cover. To facilitate removal, you can spray around the contour with WD-40 lubricant.

We carefully take out the insides, remembering the location of the parts and laying them out in order. We take out the rotor with plates. Remove the sealing rubber ring by prying it with a screwdriver. Pull out the working cylinder (stator).

On its top side there are marks (letter and number) for correct installation.

Below is another plate, a spring and an oil seal.

After disassembly, we wash all the parts with white spirit and carefully inspect.

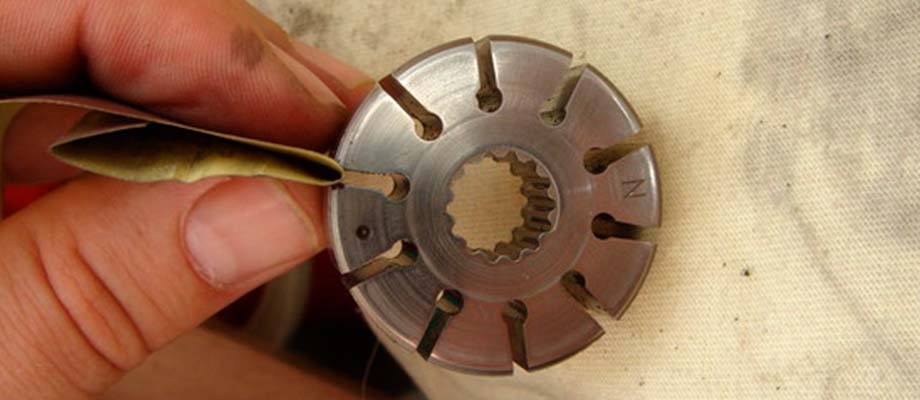

We pay attention to the state of the grooves of the rotor drum, their edges must be even, sharp and free of burrs and other defects that may interfere with the free movement of the blades.

Otherwise, irregularities must be eliminated with a needle file and sandpaper. You should also carefully function the plates themselves (blades). Avoid overzealousness and do not overdo it.

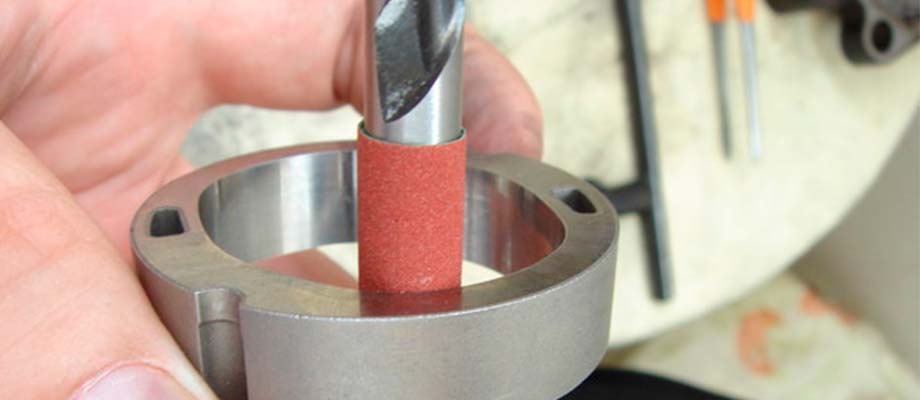

The inner elliptical surface of the working cylinder must be smooth. Often it is the defects of the ellipse that are the cause of the poor performance of the pump. If there are grooves or gouges from the blows of the blades, they will have to be sanded.

The process of manual grinding is quite long and laborious. It can be made easier if you use an electric drill. We wrap sandpaper on a drill with a diameter of 12 mm or a little more and clamp it in the drill chuck. We grind, changing the skin as it wears out and gradually moving from coarse to finer.

To get to the bearing, you will have to knock out the shaft by tapping it with a hammer.

If the bearing is to be replaced, remove the retaining ring with a puller. then you need to press the bearing off the shaft and install a new one.

Along the way, it is worth replacing the oil seal, as well as all the o-rings and washers.

We collect everything in the reverse order. When installing the plates in the grooves of the drum, make sure that their rounded side is facing out.

After repairing the pump, it is strongly recommended to completely replace the working fluid.

It may take some time to grind the blades and stator. In this case, the pump may hum a little.