How to soundproof car arches inside and out

Content

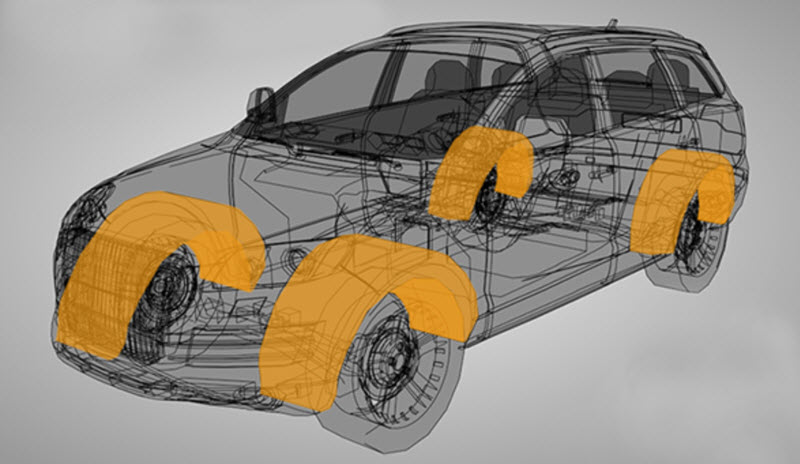

One of the components of comfort when driving a car is the silence in the cabin. Even at short distances, the noise is annoying, and if you stay in such an environment for a long time, it begins to affect safety, the driver gets tired, concentration decreases. One of the main sources of acoustic discomfort are wheel arches.

What is the soundproofing of car arches for?

Modern engines run very quietly even at high load and speed. But this cannot be said about tires, and not everything depends on the perfection of their design.

In a wheel-road combination, the second factor will always be present, no matter how expensive tires are purchased.

Multiple audio sources work:

- the tire tread, which is always embossed, with large gaps to drain water in the rain, especially if the tires are universal, with developed grooves and lugs;

- the roughness of the road surface, it cannot be made absolutely smooth, since this will negatively affect the grip of the car with the road;

- the presence of road dirt, small stones and sand under the wheels;

- in rain, the tread will squeeze out jets of water from the contact zone, flying at high speed, including those hitting the elements of space inside the wheel arches;

- the resonant nature of the design of the arches, there are sheets of metal and plastic of a large area, weakly fixed and creating the same effect as the skin of the drum.

It is the latter phenomenon that can be significantly mitigated in several ways:

- provide acoustic damping of shock waves, extinguishing their energy in a noise-protective viscous material;

- eliminate resonant phenomena in thin panels by increasing their mass and lowering the acoustic quality factor;

- reduce the transfer of energy from external sources to the panels by covering them with shock and wave absorbing material.

The effect of processing the arches will be especially noticeable on budget-class cars, where, for reasons of economy, special measures are hardly used at the manufacturer.

They are limited to installing plastic fender liner lockers and applying a modest layer of anti-gravel coating. Sometimes they don't even do that. We have to fix the problem on our own, increasing the class of the car in terms of the noise level in the cabin.

How to silence the arches in the car

It would be best to place layers of noise insulation on both sides of the fender and mudguard that form the wheel arch. As you can see from the list of causes of noise, this will reduce all factors of sound penetration through niche panels.

Internal

From the side of the road, the path of sound must be blocked at the level of the surfaces of the mudguard, directly facing the reverse side into the body space. But the wing will also require processing, since it also emits sound from the outside, indirectly entering the cabin through the outer panels. That is, the entire surface of the wheel niche should be covered.

There are two ways of coating - applying a liquid layer, which partially hardens after drying or polymerization, but remains in a semi-soft state, as well as pasting with vibration-absorbing sheet material. Both methods can be combined to enhance the effect.

For liquid application, various mastics and other polymer-based or petroleum-based compounds are used, giving a sufficiently thick and durable layer. Experience shows that the best effect is obtained when using composite compounds specially designed for wheel arches.

They include a bitumen-polymer filler interspersed with rubber particles and other porous materials with a gas microstructure.

The presence of a solvent allows you to work with a sprayer and a compressor, then it evaporates, and the composition is firmly held on the surface, while giving the parts additional resistance to corrosion.

The second method consists in pasting the surfaces with sound-absorbing mats made using sandwich technology. This is a combination of a damping soft layer with reinforcing and reflective sheets. Such vibration protection is widely available for sale, has strength and all other necessary properties.

The presence of a factory coating complicates the task. It is not recommended to remove it, but it is not always reasonable to apply a heavy sandwich on it, the adhesion strength to the metal is insufficient. In these cases, the issue is resolved individually by an experienced master.

It is possible to apply liquid mastic to the protected metal, and the locker is pasted over with vibration protection sheets. But its material must provide adhesion of the adhesive layer, which is not always possible.

Some mudguards are made of a porous material that does not hold anything. It may be necessary to replace cheap factory lockers with more durable ones. You will also have to strengthen their fastening in a niche.

Outside

Outside, it is enough to simply paste over the arch with vibration protection panels. For a more complete effect, it is recommended to combine two technologies, anti-noise material with vibration damping.

There is no danger of gravel impacts here, so the strength requirements are less stringent. The outside can also be treated with mastic to protect against moisture and further attenuate the acoustics.

Sequence of work

It is best to carry out the treatment on a new car, until all surfaces are clogged with dirt at the micro level, the adhesion of the factory layers is not broken, and corrosion has not yet begun.

- The space under the arches is freed as much as possible from the fender liner and other plastic shields, for which the car is hung out, the wheels are removed, the hubs are closed from contamination.

- Niches are thoroughly washed, dried and degreased. Any contamination will weaken the adhesion of the protection to the metal.

- In the case of a liquid coating, it is applied by spraying, then dried and painted to protect against moisture.

- More effective protection consists of two layers - vibration isolation and anti-noise sheets. First, the vibration damper is glued according to the instructions for the material. It usually needs to be heated up with an industrial hair dryer for a soft and complete adhesion to the surfaces. Sheets are pre-cut in place.

- Noise protection is applied on top of the vibration isolation, these are lighter sheets. Outside, they can be protected with mastic or anti-gravel.

- Lockers are processed in the same way, first you need to make sure that their material supports gluing using this technology. One layer of universal protection is enough here. Flexible fender liner won't hold heavy ground.

- The fastening of the lockers is reinforced with additional self-tapping screws, the places of their contact with the metal must be protected with a penetrating compound for hidden cavities.

If you are not confident in your abilities, you should contact the experts. The harm caused by an illiterate soundproofing installation is easy to underestimate.

If the coating causes the factory protective layers to peel off, then rapid and not always immediately noticeable corrosion will occur.

Body parts will be irrevocably damaged, and a heavy locker that has come off can initiate an emergency.