How are modern cars driven?

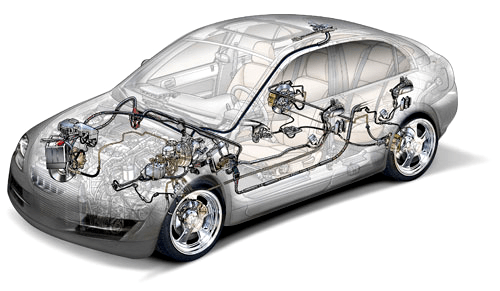

Most people who have been inside a car are familiar with the steering wheel and what it is used for. Most people who have been out of a car are familiar with front wheels and the fact that they can turn to face left or right. Few people actually know how the steering wheel and front wheels are connected, and even fewer people are aware of the precise engineering required to make a modern car handle so predictably and consistently. So what makes it all work?

Top down

Modern vehicles use a steering system called rack and pinion steering.

The steering wheel is in front of the driver's seat and is responsible for giving the driver feedback on what the wheels are doing, and also allows the driver to control which direction the wheels are pointing by turning the wheel. They come in many shapes and sizes, and some include airbags and controls for other vehicle systems.

A shaft, properly named the steering shaft, runs from the steering wheel through the car's firewall. Many new cars have steering shafts that break in the event of an accident, preventing serious injury to the driver.

At this point, in a vehicle with hydraulic power steering, the steering shaft enters directly into the rotary valve. The rotary valve opens and closes as it rotates to allow pressurized hydraulic fluid to assist the steering shaft in turning the pinion gear. This greatly facilitates handling, especially at low speeds and when stopped.

- Hydraulic power steering uses a hydraulic pump driven by a belt connected to the vehicle's engine. The pump pressurizes the hydraulic fluid and the hydraulic lines run from the pump to a rotary valve at the base of the steering shaft. Many drivers prefer this type of power steering, both for its practicality and for the feedback it gives the driver. For this reason, most sports cars have used hydraulic power steering or not at all for decades. However, recent advances in electric power steering have ushered in a new era of electric power steering sports cars.

If the vehicle has an electric motor installed along the steering shaft instead, the vehicle is equipped with electric power steering. This system provides great flexibility in choosing where to install the electric motor, making it ideal for retrofitting older vehicles. This system also does not require a hydraulic pump.

- Electric power steering uses an electric motor to help turn either the steering shaft or the pinion gear directly. A sensor along the steering shaft determines how hard the driver is turning the steering wheel and sometimes also determines how much force was applied to turn the steering wheel (known as speed sensitivity). The car's computer then processes this data and applies the appropriate force to the electric motor to help the driver steer the car in the blink of an eye. While this system is cleaner and requires less maintenance than a hydraulic system, many drivers say the electric power steering feels too out of the way and can help too much in many cases. However, electric power steering systems improve with each model year, so this reputation is changing.

If there is nothing at the end of the steering shaft other than the drive gear, then the car does not have power steering. The gear is located above the steering rack.

- The steering rack is a long metal bar that runs parallel to the front axle. The teeth, arranged in a straight line along the top of the rack, align perfectly with the drive gear teeth. The gear rotates and moves the steering rack horizontally left and right between the front wheels. This assembly is responsible for converting the rotational energy of the steering wheel into left and right movement, useful for moving the two wheels in parallel. The size of the pinion gear relative to the steering rack determines how many revolutions of the steering wheel it takes to turn the car a certain amount. Smaller gear means lighter spin of the wheel, but more revs to get the wheels to turn all the way.

Tie rods sit at both ends of the steering rack

- Ties are long, thin connecting pieces that only need to be very strong when pressed or pulled. A force at a different angle could easily bend the rod.

The tie rods connect to the steering knuckle on both sides, and the steering knuckles control the wheels to turn left and right in tandem.

The thing to keep in mind about the steering system is that it's not the only system in the car that needs to be driven precisely at speed. The suspension system also makes quite a lot of movement, which means that a turning car going over a bumpy surface is better off being able to move the front wheels side to side and up and down at the same time. This is where ball joints come in. This joint looks like a ball joint on the human skeleton. This component provides free movement, allowing very dynamic steering and suspension systems to work in tandem.

Maintenance and other concerns

With so many movements to control under a lot of force, the steering system can really take a hit. The parts are designed to support the weight of a car turning sharply at top speed. When something eventually fails and goes wrong, it's usually due to long wear and tear. Strong impacts or collisions can also break components more noticeably. A broken tie rod can cause one wheel to turn and the other to stay straight, which is a very bad scenario. A worn ball joint can squeak and make steering a little clunky. Whenever a problem occurs, be sure to have it checked immediately to ensure vehicle safety and drivability.