How are pump injectors in diesel engines arranged?

Content

- Pump nozzles - design and design solutions

- Pump nozzles - principle of operation

- Injection pumps - principle of operation and advantages

- How does an injection pump engine work? Solution Disadvantages

- Are pump injectors durable in a car?

- Pump injectors and engine head design

- Pump injection - regeneration of damaged fuel supply elements

- Injector pump or injection pump - which engine to choose

- Chip tuning of the engine and pump injector - is it worth it?

As the name suggests, pump injectors are a combination of a pump and an injector. Of course, this is a big simplification and does not tell everything about this decision, but it is very close to the truth. Each injector has its own high pressure fuel assembly. This solution has its advantages, but there are also serious disadvantages. How do pump injectors work and how to regenerate them? Look for answers in our text!

Pump nozzles - design and design solutions

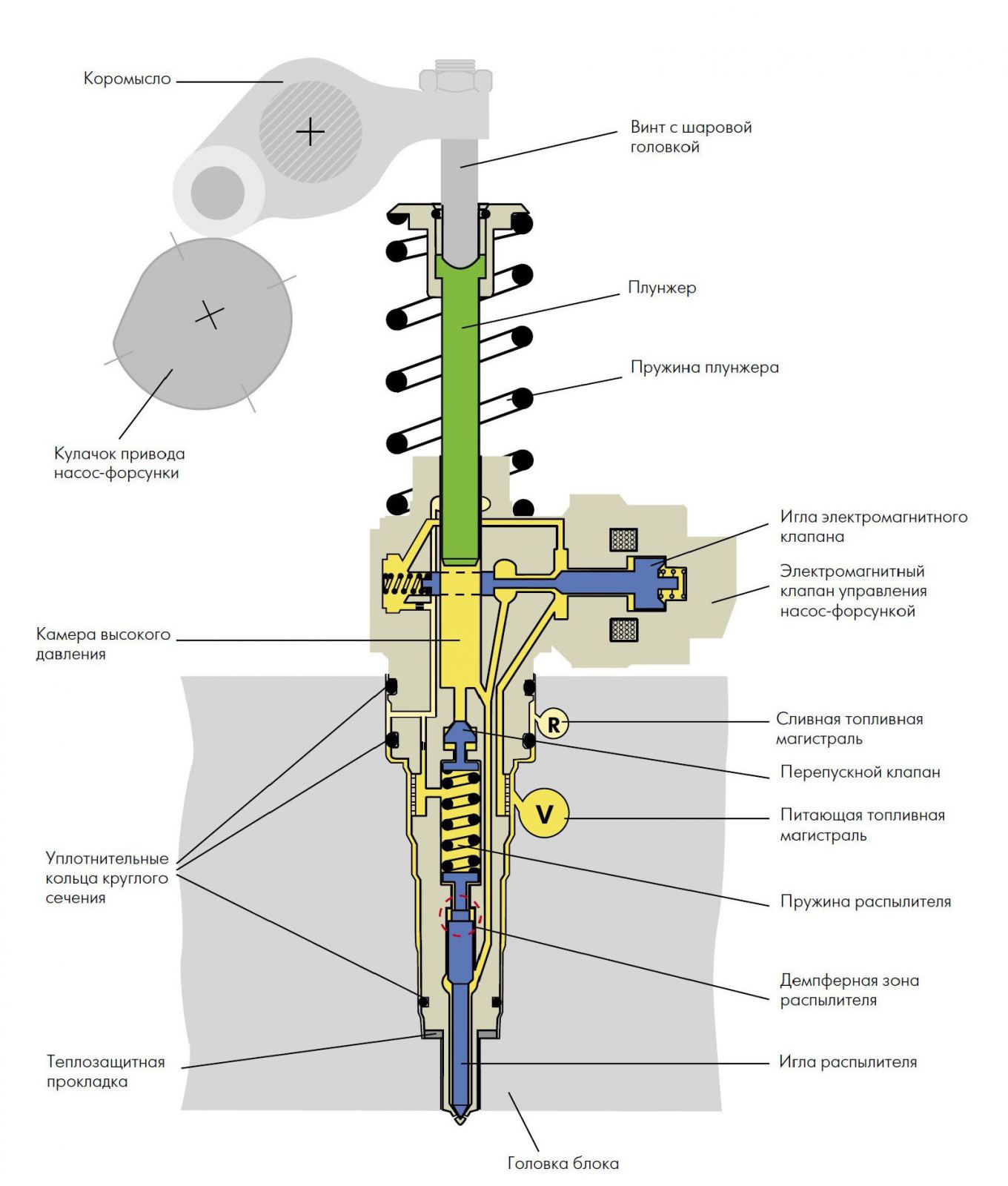

This device is a key power element in diesel engines. It consists of a nozzle combined with a cylinder. The latter is responsible for increasing the pressure of the fuel present in it. Pump injectors are simply injectors with an additional pump section that works on the same principle as in a high pressure pump. Each nozzle has its own section. In addition, the team is equipped with:

- high and low pressure lines;

- dosing shut-off valve;

- spire;

- springs;

- suffocation;

- bypass valve.

Pump nozzles - principle of operation

In traditional engines with high pressure fuel pumps, the rotational movement of the gear wheel is transmitted to the core of the injection apparatus. This is expressed in the work of individual elements. Thus, fuel pressure is created, which in compressed form enters the nozzles. Unit injectors work differently because the movement that provides the energy to operate them comes from the camshaft lobes. Here is the working principle:

- a quick jump of the cams causes the piston to move in the fuel section and create the desired pressure;

- the force of the spring tension is exceeded and the nozzle needle is raised;

- fuel injection starts.

Injection pumps - principle of operation and advantages

The undoubted advantage of using unit injectors is the very high pressure of the atomized diesel fuel. In some cases, it reaches 2400 bar, which can compete with the current Common Rail system. Pump injectors also reduce the presence of other moving parts of the engine, which reduces the cost of its maintenance (at least in theory).

How does an injection pump engine work? Solution Disadvantages

Here we turn to the disadvantages of this solution, because the diesel works very hard and loud. The pressure in the pump section rises briefly and quickly, which causes noise. In addition, unit injectors cannot perform more than two injection phases. This makes it difficult to mute the operation of the drive device. Such units do not meet stringent emission standards, so new diesel engines are equipped with common rail systems.

Are pump injectors durable in a car?

It must be admitted that the design is considered by professionals to be very effective and quite durable. If the driver takes care of refueling with high-quality fuel and regular replacement of the fuel filter, a mileage of 250-300 thousand kilometers without regeneration is quite real. There is another key issue, i.e. change the oil to the one recommended by the manufacturer. The pump injectors are driven by a camshaft that has more cams than other models. Filling with a different type of oil can lead to failure of the elements responsible for transferring energy to the piston of the fuel section.

Pump injectors and engine head design

Here another difficulty arises. In the power unit, long power lines and the entire high-pressure fuel pump with its drive have been eliminated. The complex design of the engine head does not help, which forces the driver to properly control the vehicle. It is especially important to take care of regular oil change intervals. One of the sores is knocking out the nests into which the injection pump is soldered. Then you will have to start the socket bushings or replace the whole head.

Pump injection - regeneration of damaged fuel supply elements

How is the work going? At the beginning, the specialist inspects the device and disassembles it. Precise cleaning and diagnostic equipment allows him to determine the degree of wear of components. Based on this and after clarifying the costs with the customer (usually it should be), it is necessary to determine the scope of the repair. In critical situations, when regeneration is not possible, it is necessary to replace the unit injectors with new or regenerated ones.

Injector pump or injection pump - which engine to choose

A properly running engine equipped with unit injectors is not a malfunction. However, the market is dominated by Common Rail solutions, and the technology we describe will gradually die out. If you are comfortable with a heavier engine operation, you can choose the option with unit injectors. They certainly have fewer components that can be damaged. In units with high-pressure fuel pumps, there are definitely more of them, but it forgives a little more negligence, for example, in the matter of pouring oil.

Chip tuning of the engine and pump injector - is it worth it?

As with any modern diesel, a significant increase in power can be achieved by simply changing the engine map. Professionally performed chip tuning does not affect the operation of the unit injectors. There will be no constructive contraindications to its implementation. The second question is, of course, the quality of the components themselves at the time of the changes. Usually, as power increases, the level of operation of the engine also increases, which can adversely affect its service life.

Pump injection is a technological solution, which, however, does not meet emission standards and will fade into the background. Is it worth it to buy a car that is equipped with it? This is strongly influenced by the condition of the engine and the unit injectors themselves. Weigh all the pros and cons we have outlined and make a wise decision.