How to replace the air fuel ratio sensor

Content

The air-fuel ratio sensor is faulty in the vehicle if the check engine light comes on. Poor engine performance occurs due to a failed oxygen sensor.

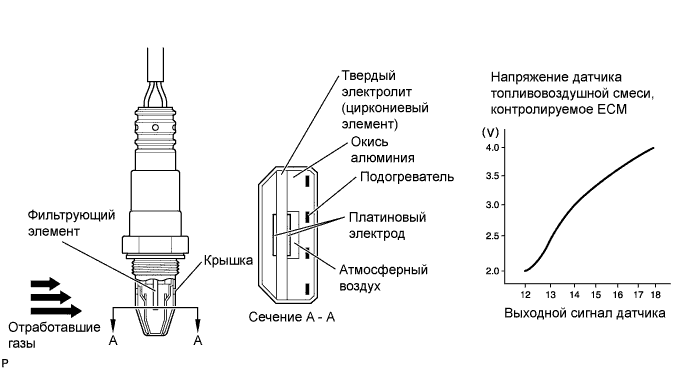

Air-fuel ratio sensors, commonly known as oxygen sensors, tend to fail in the vehicle's handling system. When this sensor fails, the engine does not run optimally and can pollute the environment.

Usually the engine light will come on, informing the operator that something is not working properly. The indicator light associated with the air fuel ratio sensor will turn amber.

Part 1 of 7: Fault Indicator Light Identification

When the engine light comes on, the first thing to do is scan the car's computer for codes. During the scan, various codes may appear, indicating that something inside the engine has caused the air-fuel ratio sensor to fail.

The following are the codes associated with the air fuel ratio sensor:

P0030, P0031, P0032, P0036, P0037, P0038, P0042, P0043, P0044, P0051, P0052, P0053, P0054, P0055, P0056, P0057, P0058, P0059, P0060, P0061, P0062, P0063, P0064, P0131, P0132.

Codes P0030 to P0064 will indicate that the air fuel ratio sensor heater is shorted or open. For codes P0131 and P0132, the air fuel ratio sensor has either a defective heater or a thermal shock crash.

If you have scanned the vehicle's computer and found codes other than those listed, perform diagnostics and troubleshooting before replacing the air fuel ratio sensor.

Part 2 of 7: Preparing to Replace the Air Fuel Ratio Sensor

Having all the necessary tools and materials in place before starting work will allow you to get the job done more efficiently.

Necessary materials

- Jack

- Jack stands

- Wheel chocks

Step 1: Park your vehicle on a level, firm surface.. Make sure the transmission is in park (for automatic transmission) or 1st gear (for manual transmission).

- Attention: Only for vehicles with AWD or RWD transmission.

Step 2: Install wheel chocks around the rear wheels.. Apply the parking brake to block the rear wheels from moving.

Step 3: Install a nine volt battery in the cigarette lighter.. This will keep your computer running and save the current settings in the car.

If you don't have a nine volt battery, that's fine.

Step 4: Open the car hood to disconnect the battery.. Remove the ground cable from the negative battery terminal by disconnecting power to the air-fuel ratio sensor.

- AttentionA: If you have a hybrid vehicle, use the owner's manual only to disconnect the small battery. Close the car hood.

Step 5: Raise the car. Jack up the vehicle at the indicated points until the wheels are completely off the ground.

Step 6: Install Jacks. Place jack stands under the jacks, and then lower the vehicle onto the stands.

For most modern cars, the jack points are on a weld right under the doors along the bottom of the car.

- FunctionsA: It is best to follow the vehicle owner's manual for the correct jacking location.

Part 3 of 7: Removing the air fuel ratio sensor

Necessary materials

- Air fuel ratio (oxygen) sensor socket

- socket wrenches

- Switch

- Clasp remove

- portable flashlight

- Ratchet with metric and standard sockets

- Thread Pitch Sensor

Wrench

Attention: The handheld flashlight is only for gauges with icing, and the clasp is only for cars with engine guards.

Step 1: Get the Tools and Creepers. Go under the car and locate the air-fuel ratio sensor.

When locating, determine if you need to remove the exhaust or component to gain access to the sensor using the socket.

If you need to remove the exhaust pipe to get to the sensor, locate the nearest mounting bolts to the front of the sensor.

Remove butt connectors with upstream sensor and downstream sensor. Remove the bolts from the exhaust pipe and lower the exhaust pipe to access the sensor.

- Attention: Be aware that the bolts may break due to rust and severe seizing.

If the exhaust pipe runs around the drive shaft (front drive shaft for XNUMXWD vehicles or rear drive shaft for XNUMXWD vehicles), the drive shaft must be removed before lowering the exhaust pipe.

Remove the mounting bolts from the drive shaft and insert this part of the drive shaft into the sliding fork. If your vehicle's driveshaft has a center support bearing, you will also need to remove the bearing to lower the driveshaft.

If the vehicle is equipped with an engine guard, you will need to remove the guard to get to the exhaust pipe. Use a fastener remover to remove the plastic fasteners holding the engine guard. Lower the engine cover and place it out of the sun.

Step 2: Disconnect the harness from the air fuel ratio sensor.. Use the breaker and air fuel ratio sensor socket and remove the sensor from the exhaust pipe.

Some air fuel ratio sensors can get stuck on the exhaust pipe and be nearly impossible to remove. At this time, you will need a small portable flashlight.

After you use the burner, use the breaker and air fuel ratio sensor socket to remove the sensor from the exhaust pipe.

Attention: Use a portable flashlight to make sure that there are no flammable substances or fuel lines near the exhaust pipe. Use a portable torch and heat the area around the sensor mounting surface.

A warning: Be careful when you place your hands, as the surface of the exhaust pipe will glow red and be very hot.

Step 3: Clean the vehicle's wiring harness with an electrical contact cleaner.. After spraying onto the contacts, wipe off any remaining debris with a lint-free cloth.

Take the new sensor out of the box and clean the contacts with an electrical contact cleaner to make sure there is no debris on the contacts.

Part 4 of 7: Install the new air fuel ratio sensor

Step 1: Screw the sensor into the exhaust pipe.. Tighten the sensor by hand until it stops.

Torque the transducer according to the specifications on the label on the bag or box in which the transducer is shipped.

If for some reason there is no slippage and you do not know the specifications, you can tighten the sensor 1/2 turn with 12 metric threads and 3/4 turn with 18 metric threads. If you do not know the thread size of your sensor, you can use a gauge thread pitch and measure the thread pitch.

Step 2: Connect the air fuel ratio sensor butt connector to the vehicle's wiring harness.. If there is a lock, make sure the lock is in place.

If you had to reinstall your exhaust pipe, make sure you use new exhaust bolts. Old bolts will be brittle and weak and will break after a while.

Connect the exhaust pipe and tighten the bolts to specification. If you don't know the specifications, finger-tighten the bolts 1/2 turn. You may need to tighten the bolts an additional 1/4 turn after the exhaust is hot.

If you had to reinstall the driveshaft, make sure you tighten the bolts to factory settings. If the bolts are tightened to the yield point, they must be replaced.

Reinstall the engine cover and use the new plastic tabs to prevent the engine cover from falling off.

- Attention: After installation, lubricate the sliding fork and universal joint (if equipped with an oil can)

Part 5 of 7: Lowering the car

Step 1: Raise the car. Jack up the vehicle at the indicated points until the wheels are completely off the ground.

Step 2: Remove Jack Stands. Keep them away from the car.

Step 3: Lower the car so that all four wheels are on the ground.. Pull out the jack and set it aside.

Step 4: Remove the wheel chocks. Set it aside.

Part 6 of 7: Connecting the Battery

Step 1: Open the car hood. Reconnect the ground cable to the negative battery post.

Remove the nine volt fuse from the cigarette lighter.

Step 2: Tighten the battery clamp. Make sure the connection is good.

Part 7 of 7: Engine check

Step 1: Start and run the engine. Release the parking brake.

Move the vehicle to a well ventilated area and allow the engine to warm up to operating temperature.

Attention: Be aware that the engine light may still be on.

Attention: If you did not have a XNUMX-volt energy-saving device, the engine indicator will be off.

Step 2: Stop the engine. Let the engine cool down for 10 minutes and restart.

You will need to complete this step nine more times if the engine light is off. This cycles through your vehicle's computer.

Step 3: Test drive the car. Drive your car for about a block for about a mile or two to make sure there are no leaks in your exhaust system.

It will take some time to verify that the engine light is no longer on. You will have to drive your car 50 to 100 miles to see if the check engine light comes on again.

If the engine light comes back on after 50 to 100 miles, then there is another problem with the car. You will need to check the codes again and see if there are signs of unexpected problems.

The air fuel ratio sensor may need additional testing and diagnostics. There may be another underlying problem such as a fuel system issue or even a timing issue. If the problem persists, you should seek the help of one of AvtoTachki's certified technicians to carry out an inspection.