How to replace the clutch cable adjuster

Content

Clutch cables tend to stretch, causing the clutch to not engage properly. As the clutch cables wear, so does the adjuster. Some clutch cables have a built-in adjuster attached to the clutch cable housing. The other clutch cables are attached to the external adjuster.

Clutch cable adjusters, which are located on or outside of the clutch cable, are commonly found on pickup trucks, XNUMXxXNUMXs, diesel pickup trucks, diesel trucks, and motorhomes.

Clutch cable adjusters located on the clutch cable are commonly found on foreign and domestic vehicles, vans and small to medium sized SUVs.

Part 1 of 5: Checking the Condition of the Clutch Cable Adjuster

With the engine running and a large area around the vehicle, depress the clutch pedal and attempt to shift the vehicle into gear by moving the shift lever to the gear of your choice. If you start to hear a grinding sound when you try to move the shift lever, this indicates that the clutch cable adjuster is out of adjustment or damaged.

- Attention: If you start the vehicle and hear a loud click and notice that the clutch pedal is hitting the floor mats in the cab, stop the engine immediately as the clutch fork is hitting the clutch springs.

Part 2 of 5: Getting Started

Necessary materials

- Jack

- Jack stands

- Wheel chocks

Step 1: Park your vehicle on a level, firm surface.. Make sure the gearbox is in neutral.

Step 2: Apply the parking brake to the rear wheels of the vehicle.. Install wheel chocks around the rear wheels of the vehicle, which will remain on the ground.

Step 3: open the hood. This will allow you to access the engine compartment.

Step 4: Raise the car. Using a floor jack suitable for the weight of the vehicle, raise it at the indicated jack points until the wheels are completely off the ground.

Step 5: Install Jacks. The jack stands should be located under the jacking points.

Then lower the car onto the jacks. For most modern cars, the jack stand attachment points are on a weld right under the doors along the bottom of the car.

- Attention: It is best to follow the vehicle owner's manual to determine the correct location for the jack.

Part 3 of 5: Removing the External Clutch Cable Adjuster

Necessary materials

- socket wrenches

- reptile

- Pliers with needles

- Ratchet with metric and standard sockets

- Wrench

Step 1: Locate the clutch pedal adjuster.. Locate the clutch pedal adjuster in the cab of the vehicle on the driver's side.

Step 2: Remove the cotter pin. Using needle nose pliers, you will need to remove the cotter pin holding the slotted anchor pin at the end of the clutch cable.

Remove the cable from the regulator.

Step 3: Remove the regulator lock nut and remove the mounting nut.. Remove the clutch cable adjuster.

If you have an inline adjuster attached to the clutch cable housing, you will need to replace the clutch cable.

- Attention: You will need to remove the clutch cable to replace the integrated clutch cable adjuster.

Step 4: Install the mounting nut. Torque to the specifications supplied with the external regulator.

If instructions for installing an external regulator were not provided, finger-tighten the nut, then tighten the mounting nut an additional 1/4 turn.

Step 5: Install the lock nut by hand tightening. Tighten the lock nut 1/4 turn to apply the holding force.

Step 6: Install the slotted anchor pin into the regulator.. Using needle nose pliers, install a new cotter pin into the slotted anchor pin and attach the end of the clutch cable to the external adjuster.

Step 7: Rotate the clutch cable to tension the cable.. Consult your vehicle's service manual to ensure that the clutch bearing clearance is correct.

For most vehicles, the clutch pedal clearance is 1/4" to 1/2" from the pedal pad to the floor. If the vehicle is equipped with a constant contact release bearing, there will be no play on the brake pedal.

Step 8: Raise the car. Using a floor jack, raise the vehicle at the indicated lifting points.

Step 9: Remove Jack Stands. Be sure to keep them away from the vehicle.

Step 10: Lower the car so that all four wheels are on the ground.. Pull out the jack and set it aside.

Step 11: Remove the wheel chocks. Remove them from the rear wheels and set aside.

Part 4 of 5: Checking the Assembled Clutch Cable Adjuster

Step 1: Make sure the transmission is in neutral.. Turn on the ignition key and start the engine.

Step 2: Press the clutch pedal. Move the gear selector to the option of your choice.

The switch should easily enter the selected gear. Turn off the engine when you are done with the test.

Part 5 of 5: Test driving a car

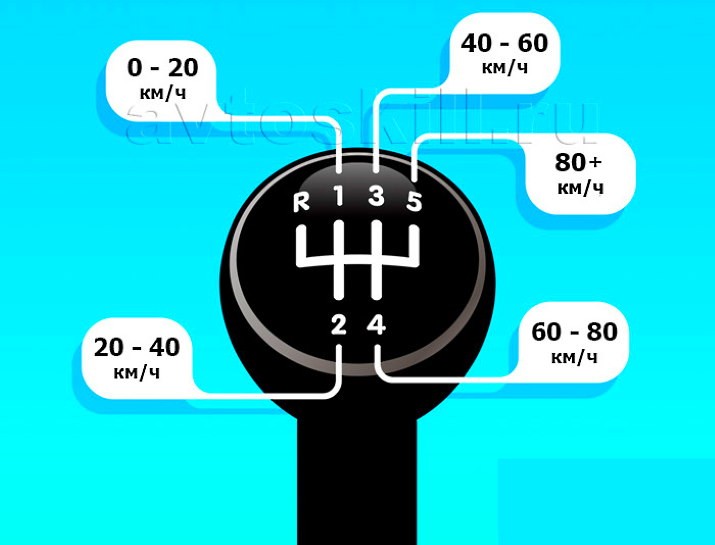

Step 1: Drive the car around the block. During the test drive, shift gears alternately from first to higher gear.

Step 2: Press the clutch pedal down. Do this when shifting from the selected gear to neutral.

Step 3: Press the clutch pedal down. Do this when moving from neutral to another gear selection.

This process is called double clutching. This ensures that the transmission draws little to no power from the engine when the clutch is properly disengaged. This process is designed to prevent clutch damage and transmission damage.

If you don't hear any grinding noise, and shifting from one gear to another feels smooth, then the clutch cable adjuster is set correctly.

If the clutch grinding sound returns, or if the clutch pedal feels too loose or too tight, you may need to tighten or loosen the clutch cable adjuster to correct the tension. If the clutch cable adjuster has been replaced but you hear a grinding sound on start up, this could be further diagnosis of the transmission clutch release bearing and fork, or a possible transmission failure. If the problem persists, you should seek the assistance of one of our certified mechanics who can inspect the clutch and transmission and diagnose the problem.