How to change a belt in a car

Content

When your engine is running, it creates power that is used for more than just acceleration. Engine power includes a belt at the front of the engine that can power additional systems such as: A/C Compressor…

When your engine is running, it creates power that is used for more than just acceleration. Engine power includes a belt on the front of the engine that can power additional systems such as:

- Air conditioning compressor

- Air pump

- Generator

- Power steering pump

- Water pump

Some vehicles have more than one belt to power additional components, while others have alternate means of powering systems. Each car model is unique in that this drive belt works.

Motor drive belts are made of reinforced rubber. Rubber is used to make belts because:

- The rubber is flexible even in cold weather.

- Rubber is inexpensive to manufacture.

- Rubber does not slip.

If the belt were made entirely of rubber, it would stretch or break under light load. It is reinforced with fibers to keep its shape and strengthen it to prevent stretching. The fibers can be cotton threads or even Kevlar threads, which give enough strength so that the belt does not lose its shape and does not stretch.

Since the belts are made of rubber, they are subject to wear and tear and the weather. When your engine is running, the belt runs over the pulleys several hundred times a minute. The rubber can heat up and wear off the belt slowly. It can also dry out and crack from heat or lack of use and eventually crack.

If your belt breaks, you may experience driving problems such as no power steering, no power brakes, the battery will not charge, or the engine may overheat. You should replace your engine drive belt at the first sign of excessive wear, cracking, or wear. Slight cracking is considered normal wear on the side of the rib and the crack should not extend to the bottom of the rib, or is considered excessive and should be replaced.

Part 1 of 4: Choosing a New V-ribbed Belt

It is imperative that your new belt is the same size and style as the belt on your vehicle. If this is not the case, you will not be able to drive your vehicle until you purchase the proper belt.

Step 1: Check the parts lists at an auto parts store.. There will be a book in the belt department that lists the correct belts for almost all modern cars.

- Find the right belt on the shelf and buy it. Be aware of additional belts for your vehicle's various accessories.

Step 2: Contact a Parts Specialist. Ask the employee at the parts counter to find the right belt for your car. Confirm model, year and options if requested. Engine size and any other parameters may be required to select the correct belt.

Step 3: Check the belt. If you can't find a listing for your belt, check the belt itself. Sometimes a belt can have legible part numbers or belt IDs even after years of use. Match this number with the number at the auto parts store.

Step 4: Physically fit the belt. If none of the other options work, remove the belt and take it to an auto parts store. Match it physically with the new belt by trial and error.

Make sure it has the same number of ribs, the same width, and the same length. The length of the new belt may only be slightly shorter than the worn belt due to the fact that the old belt can stretch.

Ask a parts specialist for help if you are not sure about the process.

Part 2 of 4. Remove poly V-belt.

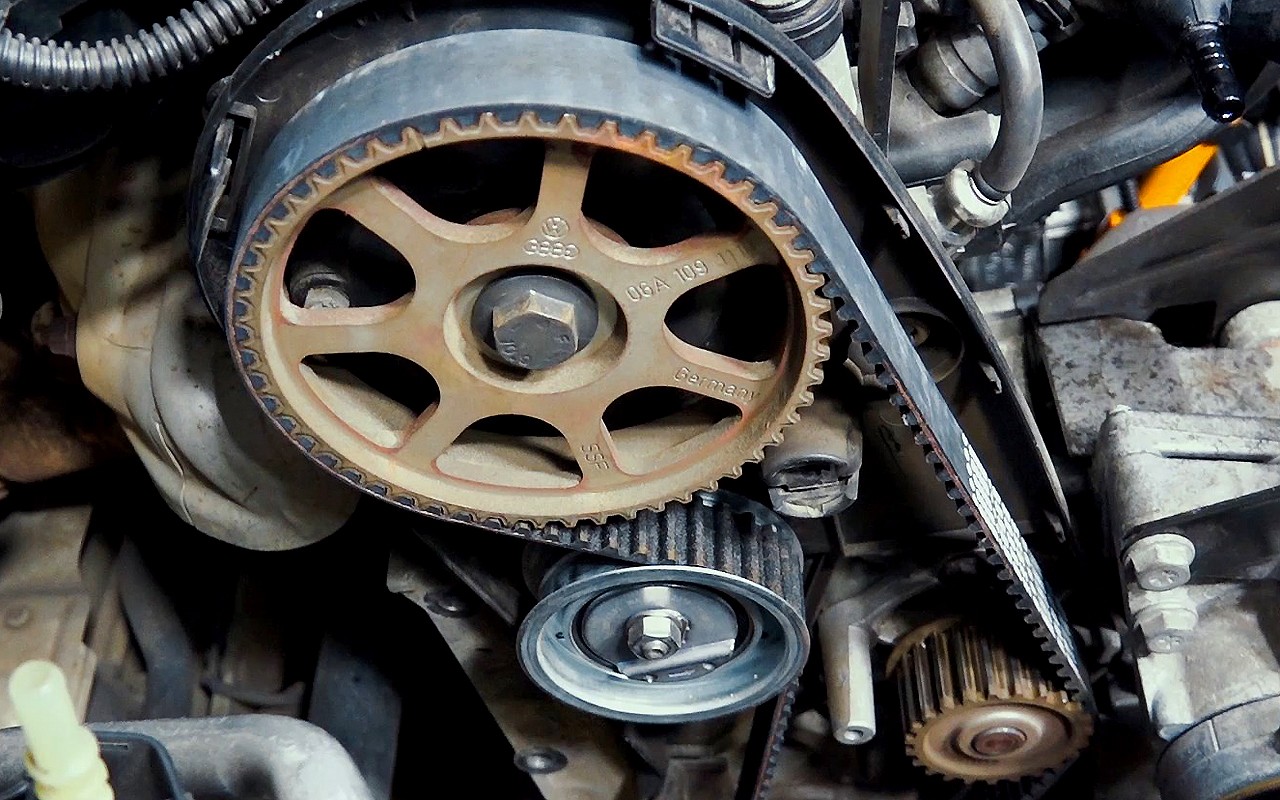

Almost all modern vehicles use a single belt that powers all of the engine's accessories. It's routed in a slightly complex fashion and held in place with tension. The serpentine belt is a flat reinforced rubber belt with several small grooves on one side and a smooth back. The grooves line up with the lugs on some of the engine pulleys, and the back of the belt runs over the smooth surfaces of the intermediate pulleys and tensioners. Some engines use a belt with grooves on the inside and outside of the belt.

Necessary materials

- belt

- Eye protection

- Gloves

- pen and paper

Ratchet and socket set (⅜”)

A warning: Always wear gloves and goggles when working under the hood of your vehicle.

Step 1: Determine the seat belt. Check under the hood for a label that shows the correct position of the engine belt.

If there is no belt routing label, draw the pulleys and belt routing with pen and paper.

A warning: It is extremely important that your new belt is installed exactly the same as the old belt, otherwise you may seriously damage the engine or other components.

Step 2: Loosen the belt tension. There are several different types of V-ribbed belt tensioners. Most newer vehicles use a spring loaded tensioner while others use a screw type adjustable tensioner.

Step 3: Use a ratchet to relieve tension. If your tensioner is spring loaded, use a ratchet to loosen the tension.

You may need to put the head on the ratchet to fit it onto the tensioner pulley bolt. Another style calls for only the ⅜” or 1/2″ square drive on the ratchet to fit into the hole on the tensioner.

Pry in the opposite direction of the belt to loosen the tension. Be careful not to pinch your fingers in the belt when removing the belt.

Step 4: Pick a Socket. If the tensioner is adjusted with a screw adjuster, align the correct seat with the adjusting bolt and install it on the ratchet.

Step 5: Loosen the tensioner adjusting bolt.. Turn the ratchet counterclockwise until the belt is loose and you can pull it off the pulleys by hand.

Step 6: remove the old belt. While holding the tensioner by the ratchet with one hand, remove the belt from one or more pulleys with your free hand.

Step 7: Loosen the tensioner. Slowly and in a controlled manner release the tensioner pulley back to its original position using a ratchet if your tensioner is spring loaded. If you release the tensioner too quickly or slip and it slams shut to stop, the tensioner may be damaged and will need to be replaced.

Part 3 of 4: Inspect the Pulleys

Step 1: Remove the old belt from the remaining pulleys.. Compare its length and width with the new belt you are about to install to make sure it is correct.

- The width of the belt and the number of ribs must be exact, and the length must be very close. The old belt may have stretched a little during use, so it may be slightly longer than the new one by an inch or less.

Step 2. Inspect the condition of the pulleys.. Locate the missing pieces of metal pulleys, check them for kinks, and spin each pulley to make sure they don't make noise or bind.

Make sure the pulleys are aligned. Look to one side to see if any of the pulleys are noticeably further back or forward.

If they do not rotate smoothly or are not aligned, you will need to fix the problem before installing a new belt. A damaged pulley or a seized component will quickly rip or destroy a new belt.

Part 4 of 4. Install the new V-ribbed belt.

Step 1: Install the new belt loosely. Slide the new belt over as many pulleys as possible. If possible, install a belt on each pulley except for the tensioner.

- Make sure that the smooth back side of the belt only contacts the smooth pulleys and the grooved side only contacts the toothed pulleys.

Step 2: Press on the tensioner. Push the tensioner with a ratchet if the tensioner is spring loaded.

- Pull it back as far as you can. It will most likely need to be tightened a little further than the old belt, as the new one is stiffer and hasn't stretched.

Step 3: Slip the belt onto the tensioner with your free hand..

- If you were unable to fully route the belt prior to this step, do so by releasing the tensioner pressure.

Step 4: Slowly release pressure on the tensioner.. Keep your hands free in case the strap slips or comes back in your direction.

- Check all pulleys to make sure the belt is properly engaged with all ribs.

Step 5: Tighten Adjustable Tensioner. If your tensioner has a screw adjuster, tighten it with a ratchet until the belt is tight between all the pulleys.

Step 6: Check Belt Deflection. Press down on the longest section of the belt between the pulleys to make sure it is tight. You should be able to control the deflection by about half an inch.

- If you have more than half an inch to an inch of deflection, the belt tensioner is weak and needs to be replaced. Do this before starting the engine. If you have an adjustable tensioner, adjust the belt even further until the sag is half an inch.

Step 7: Start the engine and watch the belt turn.. Watch the belt for a minute or two to make sure there is no squealing, grinding or smoke coming from the belt.

If there is any irregularity, immediately turn off the engine and check the belt gasket. If the belt direction is correct, you may have another mechanical problem that you should check with a certified mechanic such as AvtoTachki.

Recheck the belt tension after starting the engine for a couple of minutes to ensure that the initial belt tension does not require readjustment.

If you don't have the time or don't want a professional to do this repair for you, consider having a certified mobile mechanic like AvtoTachki help you change the drive belt.