How to replace a fiberglass handle?

Content

The fiberglass handle is held in place with epoxy or similar resin, rather than the metal wedges commonly used to secure wooden sledgehammer handles. You can also use epoxy for wooden handles.

The fiberglass handle is held in place with epoxy or similar resin, rather than the metal wedges commonly used to secure wooden sledgehammer handles. You can also use epoxy for wooden handles.Removing an old fiberglass handle

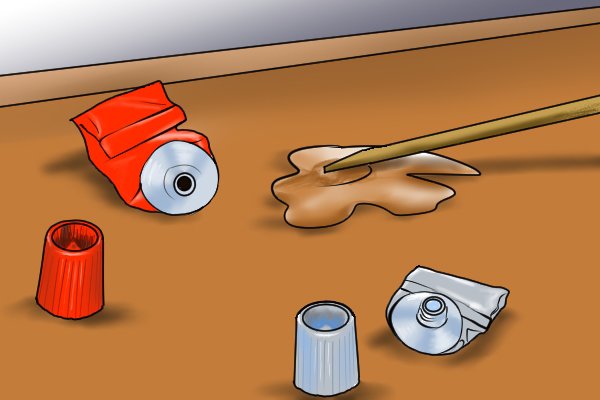

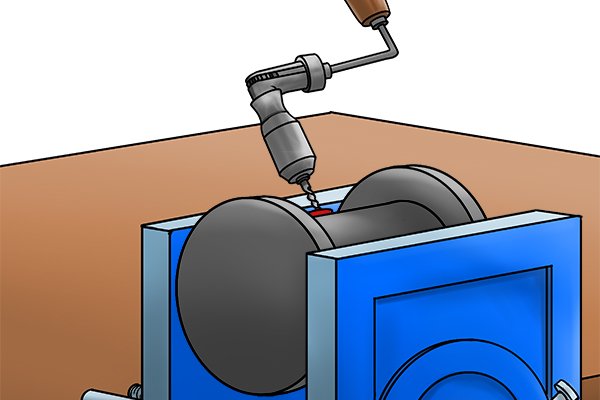

Step 1 - Secure in a vise

Secure the hammer head in a vise to protect the head. Use a hand saw with fine teeth to cut off the old handle as close to the head as possible without damaging it.

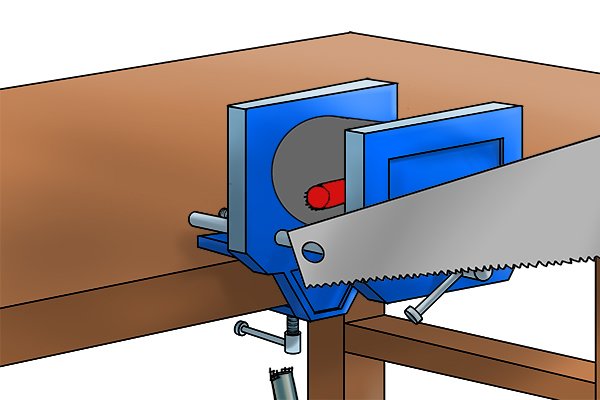

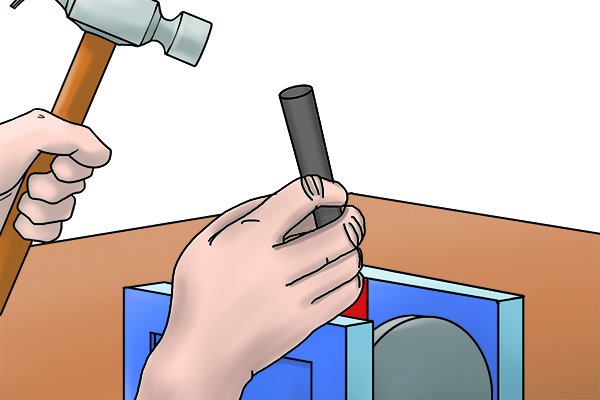

Step 2 - Remove the Remaining Handle

Using a hammer and a punch or a large bolt, remove the remnants of the handle from the eyelet of the head. It should loosen after a few hammer blows.

Step 3 - Loosen Stuck Parts

To loosen a stuck part, use a drill with a 6 mm (¼ inch) drill bit and drill through the wood. You may need to drill a few holes to remove the hard part. Use a hammer and punch to knock out the remaining handle and cut off any fiberglass shards.

Once this is removed, clean the eye of the head and remove all debris.

Installing a new fiberglass paver bit handle

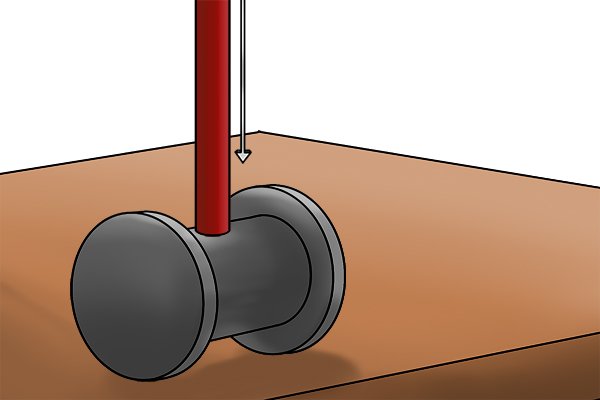

Step 4 - Insert the handle

Make sure the paver hammer head eye is clean. Epoxy will not adhere to greasy or rusty surfaces. Insert the pen shaft into the head until the top is flush with the head. You may need to file the handle to fit.

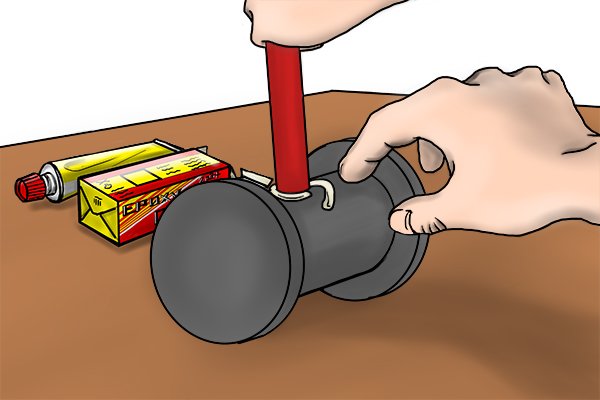

Step 5 - Seal the Handle

Seal the gap between the handle and the head with putty or caulk to prevent the epoxy from escaping. The putty or sealing cord should be pressed straight against the head to form a tight seal.

Sealing cord is a strip of putty-like material used primarily to seal drafts in windows.

Sealing cord is a strip of putty-like material used primarily to seal drafts in windows.It is usually sold in long rope-like rolls that can be cut to the desired length.

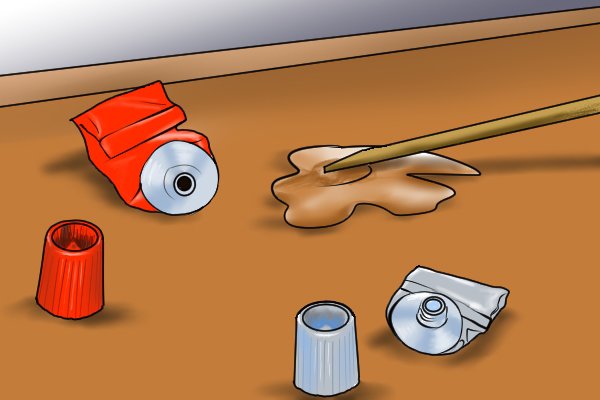

Step 6 - Mix the Epoxy

Check the instructions that came with the epoxy for proper mixing as this can vary from package to package. Gently mix the contents to avoid the formation of air bubbles, carefully ensuring a uniform consistency and color. If it is not mixed properly, the epoxy may not cure properly.

Temperature affects the curing process of epoxy, so read the manufacturer's recommendations carefully.

Step 7 - Apply Epoxy

Apply epoxy between the top of the new handle and the jackhammer head. Make sure the handle stays properly aligned at all times.

If epoxy leaks from under the o-ring, reseal by pressing the caulk firmly into any gaps.

Wipe off any excess epoxy by keeping the hammer upright to prevent leakage. Leave the epoxy to fully cure (or harden) for up to a week before using the hammer again.

Wipe off any excess epoxy by keeping the hammer upright to prevent leakage. Leave the epoxy to fully cure (or harden) for up to a week before using the hammer again.Don't forget practice makes perfect and be proud of your skill!