How to replace the ignition trigger

Content

The ignition trigger fails if the engine is misfiring or has trouble starting. The check engine light may illuminate if the ignition trigger fails.

The ignition system uses several mechanical and electrical components to start and keep the engine running. One of the most overlooked parts of this system is the ignition trigger, crankshaft position sensor, or optical sensor. The purpose of this component is to monitor the position of the crankshaft and the corresponding connecting rods and pistons. This transmits important information through the distributor and on-board computer of most new vehicles to determine the engine's ignition timing.

Ignition triggers are magnetic in nature and "fire" when the block rotates or other metal components rotate around them. They can be found inside under the distributor cap, under the ignition rotor, next to the crankshaft pulley, or as a component of the harmonic balancer found on some vehicles. When the trigger fails to collect data or stops working completely, it can cause a misfire or engine shutdown.

Regardless of the exact location, the ignition trigger depends on proper alignment in order to work efficiently. In fact, most of the time, problems with the ignition trigger result from it either coming loose or with support brackets that keep the ignition trigger secured. For the most part, the ignition trigger should last the lifespan of a vehicle, but like any other mechanical component, they may wear out prematurely.

This part is in several different places depending on the make, model, year, and type of engine it supports. It is recommended that you consult your vehicle's service manual for the exact location and steps to follow to replace the ignition trigger for your specific vehicle. The steps listed below describe the process of diagnosing and replacing the ignition trigger, most common on domestic and foreign vehicles manufactured from 1985 to 2000.

Part 1 of 4: Understanding the Symptoms of Rejection

Like any other part, a faulty or faulty ignition trigger displays several general warning signs. The following are a few typical signs that the ignition trigger is defective and needs to be replaced:

Check Engine light comes on: On most vehicles, the Check Engine light is the default warning that tells the driver that there is a problem somewhere. However, in the event of an ignition trigger, it usually fires because the vehicle's ECM has detected an error code. For OBD-II systems, this error code is usually P-0016, which means there is a problem with the crankshaft position sensor.

Problems starting the engine: If the engine will crank over, but won’t ignite, it may be caused by a malfunction within the ignition system. This may be due to a faulty ignition coil, distributor, relay, spark plug wires, or the spark plugs themselves. However, it’s also common for this issue to be caused by a faulty ignition trigger or crankshaft position sensor.

Engine misfiring: In some cases, the ignition trigger harness that relays information to the ignition coil, distributor, or the ECM comes loose (especially if it’s attached to the engine block). This may cause a misfiring situation to occur while the vehicle is under acceleration or even at idle.

- A warning: Most modern cars that have electronic ignition systems do not have this type of ignition trigger. This requires a different type of ignition system and often has a very complex ignition relay system. As such, the instructions noted below are for older vehicles that have a distributor/coil ignition system. Please refer to the vehicle’s service manual or contact your local ASE certified mechanic for assistance with modern ignition systems.

Part 2 of 4: Ignition Trigger Troubleshooting

The ignition trigger senses the movement of the crankshaft to activate the correct ignition timing when the driver wants to start the car. Ignition timing tells the individual cylinders when to fire, so an accurate measurement of the crankshaft makes this operation possible.

Step 1: Perform a physical inspection of the ignition system.. There are a few ways that you can diagnose this problem manually.

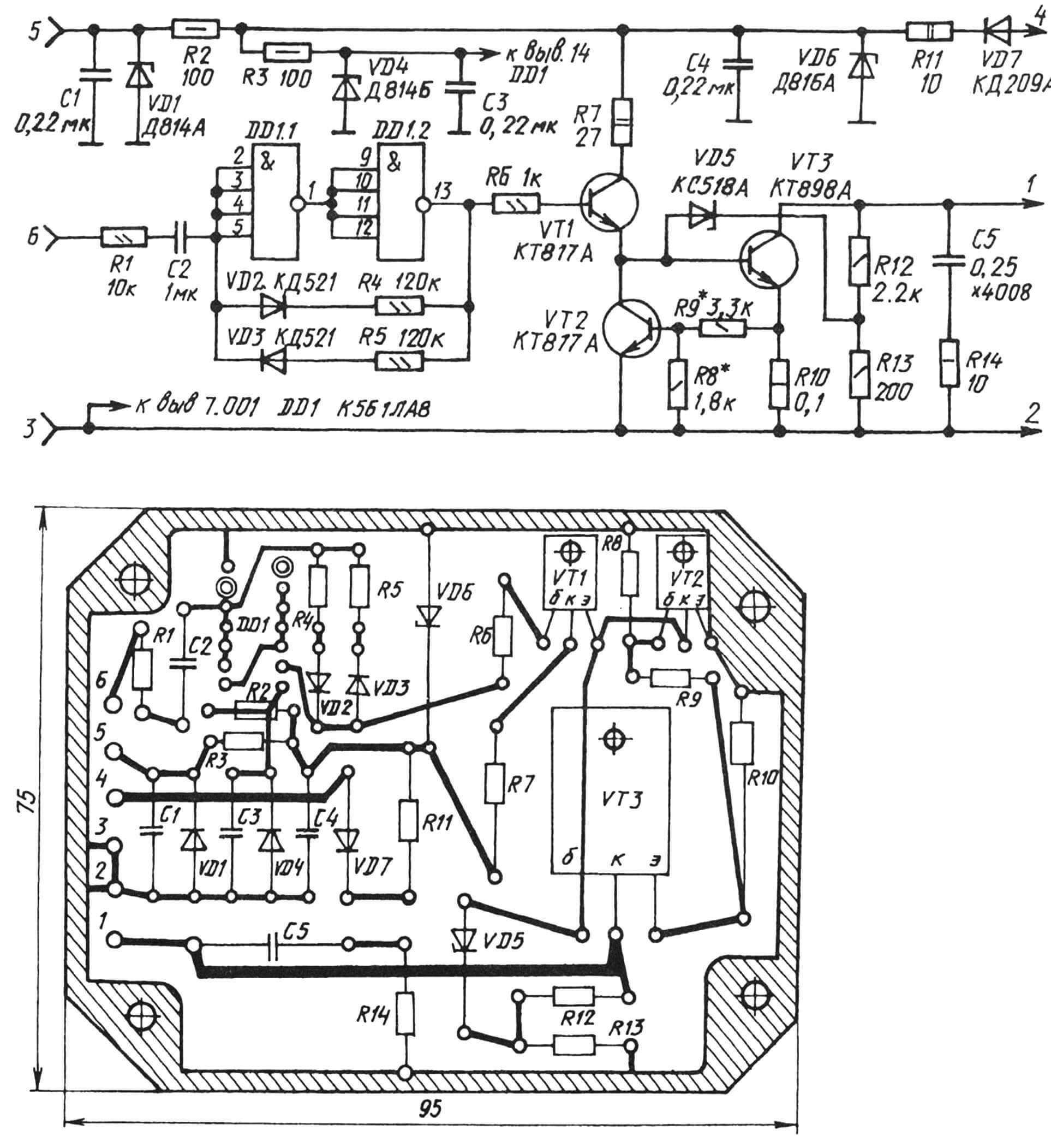

In most cases, the problems associated with a bad ignition trigger are caused by damaged wires or connectors that relay the information from component to component within the ignition system. The best way to save time, money, and resources replacing parts that aren’t damaged is to start by tracing the wires and connectors that comprise the ignition system. Be sure to use a diagram as a guide.

Look for damaged electrical wires (including burns, chafing, or split wires), loose electrical connections (ground wire harnesses or fasteners), or loose brackets holding components.

Step 2: Download OBD-II Error Codes. If the vehicle has OBD-II monitors, then usually an error with the crankshaft position sensor or ignition trigger will display a generic code of P-0016.

Using a digital scanner, connect to the reader port and download any error codes, especially if the check engine light is on. If you find this error code, it is most likely due to a faulty ignition trigger and it needs to be replaced.

Part 2 of 3: Replacing the Ignition Trigger

Necessary materials

- Boxed end wrench or ratchet sets (metric or standard)

- flashlight

- Flat and Philips screwdrivers

- New engine cover gaskets

- Ignition Trigger and Wiring Harness Replacement

- Safety glasses

Wrench

Attention: Depending on the specific vehicle, you may not need new engine cover gaskets. Below are the general steps for replacing the ignition trigger (crankshaft position sensor) on most domestic and foreign vehicles with traditional distributor and coil ignition systems. Vehicles with electronic ignition modules should be serviced by a professional. Be sure to consult your service manual for any additional steps you’ll need to take.

Step 1: Disconnect the car battery. Locate the vehicle's battery and disconnect the positive and negative battery cables before continuing.

You will be working with electrical components, so you will need to turn off all power sources before starting this project.

Step 2: Remove the engine cover. To access this part, you will have to remove the engine cover and possibly other components.

These can be air filters, air filter lines, inlet auxiliary hoses, or coolant lines. As always, check your service manual to find out exactly what you need to remove to gain access to the crankshaft position sensor or ignition trigger.

Step 3: Locate Ignition Trigger Connections. Most of the time the ignition trigger is located on the side of the engine connected to the engine block with a series of screws or small bolts.

There is a connector that goes from the trigger to the distributor. In some cases, this harness is attached to a latch on the outside of the distributor or inside the distributor, as shown. If the harness is connected outside the distributor to another electrical harness fitting, simply remove the harness from that fitting and set it aside.

If the harness is attached to the inside of the distributor, you will have to remove the distributor cap, rotor, and then remove the attached harness, which is usually held on with two small screws.

Step 4: Find the ignition trigger. The trigger itself is connected to the engine block in most cases.

It will be metallic and most likely silver. Other common locations for this component include an ignition trigger within a distributor, an ignition trigger integrated with a harmonic balancer, and an electronic ignition trigger within an ECM.

Step 5: Remove the engine cover. On many vehicles, the ignition trigger is located under the engine cover next to the timing chain.

If your vehicle is one of these, you’ll have to remove the engine cover, which might require you to remove a water pump, an alternator, or an AC compressor first.

Step 6: Remove the ignition trigger. You will need to remove the two screws or bolts that secure it to the engine block.

Step 7: Clean the joint where the ignition trigger was installed.. When you remove the ignition trigger, you will see that the connection underneath is probably dirty.

Using a clean rag, simply remove any debris under or near this connection to ensure your new ignition trigger is clean.

Step 8: Install the New Ignition Trigger into the Block. Do this with the same screws or bolts and tighten the bolts to the manufacturer's recommended torque.

Step 9: Attach wiring harness to the ignition trigger. On many ignition triggers it will be hard wired into the unit, so you can skip this step if so.

Step 10: Replace the engine cover. If this applies to your vehicle, use a new gasket.

Step 11: Connect the wiring harness to the distributor.. Also, reattach any components that needed to be removed in order to access this part.

Step 12: Refill radiator with new coolant. Do this if you needed to drain and remove the coolant lines earlier.

Step 13: Connect the Battery Terminals. Make sure they are installed the way you originally found them.

Step 14 Erase Error Codes with a Scanner. On newer vehicles with an engine control unit and a standard ignition system, the check engine light on the instrument panel will come on if the engine control unit has detected a problem.

If these error codes are not cleared before you test fire the engine, it is possible that the ECM will not allow you to start the vehicle. Make sure to clear any error codes before you test the repair with a digital scanner.

Part 3 of 3: Test driving a car

Required material

- Indicator light

Step 1: Start the car as usual. The best way to start the engine is to make sure the hood is open.

Step 2: Listen for unusual sounds. This might include clanking sounds or clicking noises. If a part was left untightened or loose, it may cause the a clanking noise.

Sometimes mechanics do not properly route the wiring harness from the ignition trigger to the distributor and can interfere with the serpentine belt if it is not properly secured. Listen for this sound when you start the car.

Step 3: Check the time. After starting the engine, check the time of your car with the time indicator.

Check your vehicle's service manual for the exact time settings and adjust if necessary.

It is always best to consult your service manual and review their recommendations in full before undertaking this type of work. If you have read these instructions and are still not 100% sure about performing this repair, have one of your local ASE certified AvtoTachki mechanics perform the ignition trigger replacement for you.