How to replace the clutch cable

Content

Clutch cables begin to wear out as the vehicle ages. However, clutch cables often fail due to overuse of the clutch. Many vehicle drivers use the clutch every time the shift lever is moved. Often, other operators operate the clutch using a float method, eliminating the need to depress the clutch pedal.

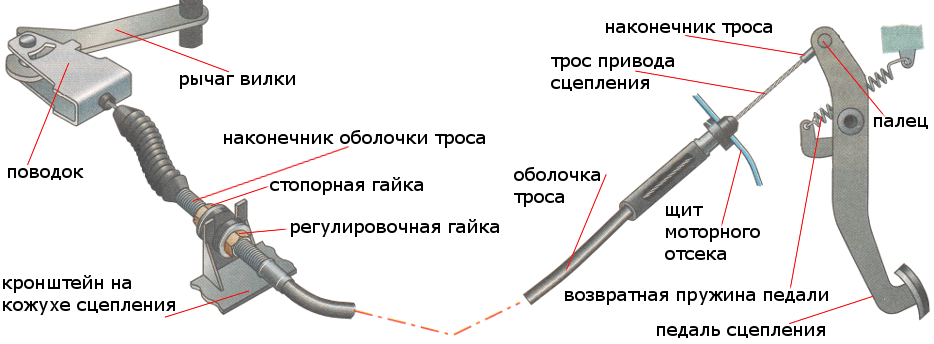

The clutch cable is different in each car depending on where it is located and what it connects to. Most clutch cables are attached to the top of the clutch pedal and then routed to the clutch fork located on the bell housing of the manual transmission. Heavy duty vehicles may have more than one clutch cable connected to the clutch fork. Most new cars use hydraulic clutch systems rather than mechanical systems.

Part 1 of 5. Check the condition of the clutch cable.

Step 1. Try to turn on the transfer.. Step on the clutch pedal and try to shift the car into gear by moving the shift lever to your chosen gear.

Be sure to do this with the engine running and with enough space around the table. If you start to hear a grinding sound when you try to move the shift lever, this is an indication that the clutch cable is not working properly.

- Attention: If you start the vehicle and hear a loud click and notice that the clutch pedal is hitting the floor mats in the cab, stop the engine immediately as the clutch fork is hitting the clutch springs.

Part 2 of 5: Clutch Cable Replacement

Having all the necessary tools and materials in place before starting work will allow you to get the job done more efficiently.

Necessary materials

- Jack

- Jack stands

- Wheel chocks

Step 1: Park your vehicle on a level, firm surface.. Make sure the gearbox is in neutral.

Step 2: Apply the parking brake to the rear wheels of the vehicle.. Install wheel chocks around the rear wheels of the vehicle, which will remain on the ground.

Step 3: open the hood. This will allow you to access the engine.

Step 4: Raise the car. Using a jack recommended for the weight of the vehicle, raise it under the vehicle at the jack points provided for it.

Do this until the wheels are completely off the ground.

Step 5: Install Jacks. The jack stands should be located under the jacking points.

Then lower the car onto the jacks. For most modern cars, the jack stand attachment points are on a weld right under the doors along the bottom of the car.

- A warning: Be sure to follow the vehicle owner's manual for the correct location for the jack.

Part 3 of 5: Clutch Cable Replacement

Necessary materials

- Hex key set

- ball hammer

- socket wrenches

- bit

- reptile

- drift kick

- Set of drills

- Electric drills

- Pliers with needles

- Ratchet with metric and standard sockets

- reverse faucet

- Soft-faced hammer

- Wrench

- Torque bit set

Step 1: Take the Tools. Locate the clutch pedal on the driver's side in the cab of the vehicle.

Step 2: Remove the cotter pin. Using needle nose pliers, you will need to remove the cotter pin holding the slotted anchor pin at the end of the cable.

If your vehicle has a bolt holding the end of the cable, you will need to remove the bolt. In some vehicles, the cable may simply go into a slot on the pedal. If so, you'll need to use needle nose pliers to pull the cable out just enough to get it out of the socket.

Step 3: Remove the brackets. Remove any bracket from the fire wall inside the cab that can secure the cable sheath.

Step 4: Pull the cable. Pull the cable through the firewall into the engine compartment.

Be aware that there will be insulated cable clamps attached along the fender and frame of the vehicle. These insulated clamps may have socket head screws or bolts or hex head bolts holding them.

Sometimes these types of mounting fixtures tend to come off because the wrong tool size is being used. When this happens, you will need to drill or gouge them.

Step 5: Get your tools and vines and get under the car.. Locate the location of the clutch fork on the gearbox housing.

In some vehicles, exhaust can interfere with the clutch fork.

If the exhaust pipe is making it difficult to reach the cable-to-bracket bolts near the clutch fork, you will need to lower or remove the exhaust pipe. Locate the nearest vehicle exhaust system mounting points.

- Attention: Be aware that the bolts may break due to rust and severe seizing. If the exhaust bolts break, you will need to drill and knock out the bolts.

Step 6: Remove the clutch cable mounting bolts from the clutch fork bracket.. Some brackets may be mounted on the gearbox housing.

Other brackets may be mounted on the rear of the engine, depending on whether the vehicle is front wheel drive or rear wheel drive.

There may be a built-in adjuster with threaded nuts on both sides, allowing the cable to move forward or backward while adjusting the cable. You will need to loosen the adjuster to make it easier to release the cable.

- A warning: I do not remember the regulator settings, because the old cable is stretched.

Step 7: Pass the end of the cable through. Make sure it goes through the slot on the clutch fork.

Step 8: After removing the cable, inspect the condition of the clutch fork.. Lubricate the grease fittings located on the clutch fork and bell housing.

Step 9: Insert the end of the cable into the slot of the clutch fork.. Attach the cable to the bracket next to the clutch fork.

- Attention: If the cable has a threaded adjuster, make sure the adjuster is fully loosened and many threads are visible.

Step 10: Run the Cable Through the Engine Bay. Wrap the insulated mounting clips around the cable housing and attach it where they came off.

Step 11: Run the Cable Through the Engine Bay Firewall. This will allow the cable to enter the cab of the car.

Step 12: Attach the end of the cable to the clutch pedal.. Install an anchor pin to hold the cable in place.

Use a new cotter pin to secure the anchor pin in place.

- A warning: Do not use the old cotter pin due to hardening and fatigue. An old cotter pin may break prematurely.

Step 13: Get under the car and tighten the adjusting nuts on the cable.. Depress the clutch pedal and measure the pedal from the shoe to the floor.

The clutch pedal should move if properly adjusted. Typically, the gap between the clutch pedal is 1/4 to 1/2 inch from the pedal pad to the floor. The recommendation is to look at the owner's manual for the correct clutch pedal clearance.

Step 14: Get under the car and tighten the lock nut against the adjusting nut.. This keeps the adjusting nut from any movement.

Step 15. Check the clutch pedal for the presence of a regulator.. The regulator will have a threaded end and be separated from the cable.

Attaches to the pedal and cable. Turn the adjuster clockwise to tension the cable. Turn the adjuster counterclockwise to loosen the cable.

Step 16: Tighten the lock nut on the back of the regulator.. This keeps the regulator from any movement.

Typically this type of clutch pedal adjuster is found on large vehicles such as pickup trucks, motorhomes, and XNUMXWD vehicles.

- Attention: Some vehicles have a constant contact clutch release bearing and do not require clutch pedal movement.

Step 17: Gather all the tools and your creeper.. Set them aside.

Step 18: Raise the car. Jack up the vehicle at the indicated points until the wheels are completely off the ground.

Step 19: Remove Jack Stands.

Step 20: Lower the car so that all four wheels are on the ground.. Pull out the jack and set it aside.

Step 21: Remove the wheel chocks. Set them aside.

Part 4 of 5: Checking the Assembled Clutch Cable

Step 1: Make sure the transmission is in neutral.. Turn on the ignition key and start the engine.

Step 2: Press the clutch pedal. Move the gear selector to the option of your choice.

The switch should easily enter the selected gear. Turn off the engine when you are done with the test.

Part 5 of 5: Test driving a car

Step 1: Drive the car around the block.

- Attention: During the test drive, shift gears from first to higher gear one at a time.

Step 2: Press the clutch pedal down. Do this when shifting from the selected gear to neutral.

Step 3: Press the clutch pedal down. Do this when moving from neutral to another gear selection.

This process is called double clutching. This ensures that the transmission draws little to no power from the engine when the clutch is properly disengaged. This process is designed to prevent clutch damage and transmission damage.

If you don't hear any grinding noise, and shifting from one gear to another feels smooth, then the clutch cable is locked correctly.

If the clutch rattle returns or the clutch pedal feels too loose or too tight, you may need to adjust the cable to lock in tension. If the clutch cable has been replaced but you hear a grinding sound on start up, this could be further diagnosis of the transmission clutch release bearing and fork, or a possible transmission failure. If the problem persists, you should seek the assistance of one of our certified mechanics who can inspect the clutch and transmission and diagnose the problem.