How to Tighten a Brake Caliper Bolt in 5 Steps

Content

The main reason for failure of the brake system is the failure of the brake caliper bolts. The problem is that in most cases it is due to the human factor. While replacing brake pads is a fairly straightforward task, the problem comes when mechanics don't take the time to properly tighten the brake caliper bolts. To help you avoid potentially catastrophic damage to your vehicle or an accident that will harm you or others, here is a simple guide on how to tighten a brake caliper bolt in 5 steps.

Step 1: Properly Remove the Brake Caliper Bolts

Like any fastener, brake caliper bolts work best when removed and installed correctly. Due to their location and tendency to corrode from debris, brake caliper bolts can become rusted and are quite difficult to remove. So, to reduce the chance of damage, proper bolt removal is an important first step. Here are 3 basic tips, but always refer to your service manual for the manufacturer's recommended actions as not all brake calipers are made from the same materials.

Use a high quality penetrating fluid to absorb rust on the bolt.

Let the bolt soak for at least five minutes before attempting to remove it.

Be sure to remove it in the correct direction. Note. Although we are all taught that the preferred method is left-handed-right tightening, some brake caliper bolts are reverse threaded. It is very important to refer to your vehicle service manual here.

Step 2. Inspect the bolt and bolt holes on the spindle.

Once you have removed the caliper bolts and removed all the parts of the brake system that need to be replaced, the next step before installing new components is to check the condition of the caliper bolt and the bolt holes located on the spindle. There is a very easy way to check the status of each of them. If you unscrew the bolt, and it is rusty, throw it away and replace it with a new one. However, if you can clean the bolt with a mild steel brush or sandpaper, it can be reused. The key is to see how well it fits into the bolt hole located on the spindle.

The bolt must turn easily into the spindle and must have zero play as you insert it into the bolt hole. If you notice play, the bolt needs to be replaced, but you also need to move on to the next important step.

Step 3: Use a thread cleaner or thread cutter to re-thread the bolt hole.

If your bolt and bolt hole fail the clearance test described above, you will need to re-tap or clean the internal threads of the bolt holes prior to installation. To do this, you will need a thread cleaner, commonly called a thread cutter, that matches your spindle threads exactly. One helpful tip: Take a brand new brake caliper bolt for your car, cut off three small sections vertically on the bolt, and hand-tighten it slowly as it slides into the bolt hole. Slowly remove this tapping tool and recheck the bolt hole you just cleaned with a new bolt.

There must be zero play, and the bolt should be easy to insert and easy to remove before tightening. If your cleaning job does not help, stop immediately and replace the spindle.

Step 4: Install all new brake system components.

Once you have verified that the brake caliper bolts and axle bolt hole are in good condition, follow your vehicle's service manual and properly install all replacement parts in the exact installation procedure and order. When it comes time to install the brake calipers, make sure you follow these 2 important steps:

Make sure the new threads have a thread blocker applied. Most replacement brake caliper bolts (especially original equipment components) already have a thin layer of threadlocker applied. If this is not the case, use a large amount of high quality threadlocker before installation.

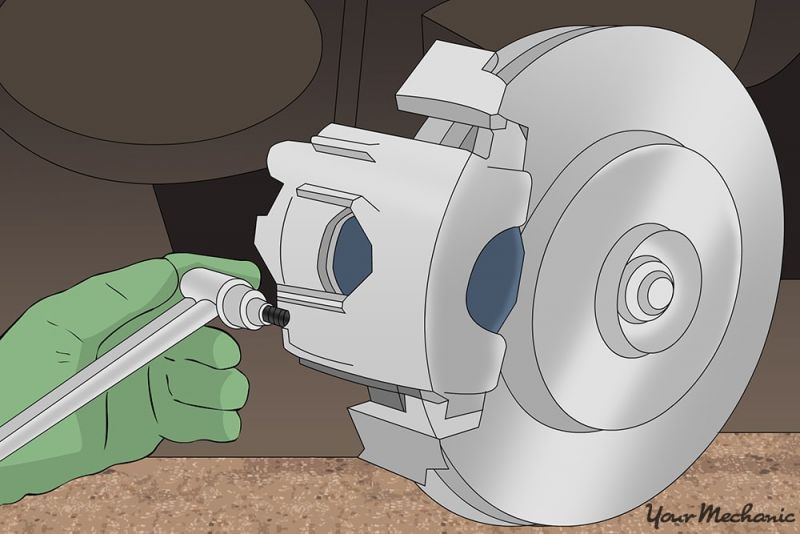

Slowly insert the brake caliper bolt into the spindle. Do not use pneumatic tools for this work. This will most likely cause the bolt to twist and overtighten.

Step 5: Use the recommended torque to tighten the brake caliper bolts.

This is where most amateur mechanics make the critical mistake of doing an internet search or asking on a public forum for the correct torque to tighten brake caliper bolts. Because all brake calipers are unique to each manufacturer and are often made from different materials, there is no universal torque setting for brake calipers. Always refer to your vehicle's service manual and look for the correct procedures for using a torque wrench on brake calipers. If you don't want to invest in a service manual, a phone call to your local dealer's service department can help.

More than a million brake pads are replaced daily by skilled mechanics in the US. Even they make mistakes when it comes to installing brake caliper bolts. The points listed above will not help you 100% avoid potential problems, but they will greatly reduce the likelihood of a failure. As always, make sure you are completely satisfied with the performance of this job, or seek advice or assistance from a professional mechanic.