What is the best material to use for a subwoofer?

Content

When creating your subwoofer and for its high-quality and loud sound, you should take into account a large number of important nuances. For example, what speaker did you purchase for the subwoofer, how correct is your box, is there enough amplifier power, is there enough power for the amplifier, etc.

In this article, we will touch on one of the many questions that will help you get closer to louder and better bass. Namely, we will answer the question, from what material is it best to make a box for a subwoofer?

Why doesn't a subwoofer play without a box?

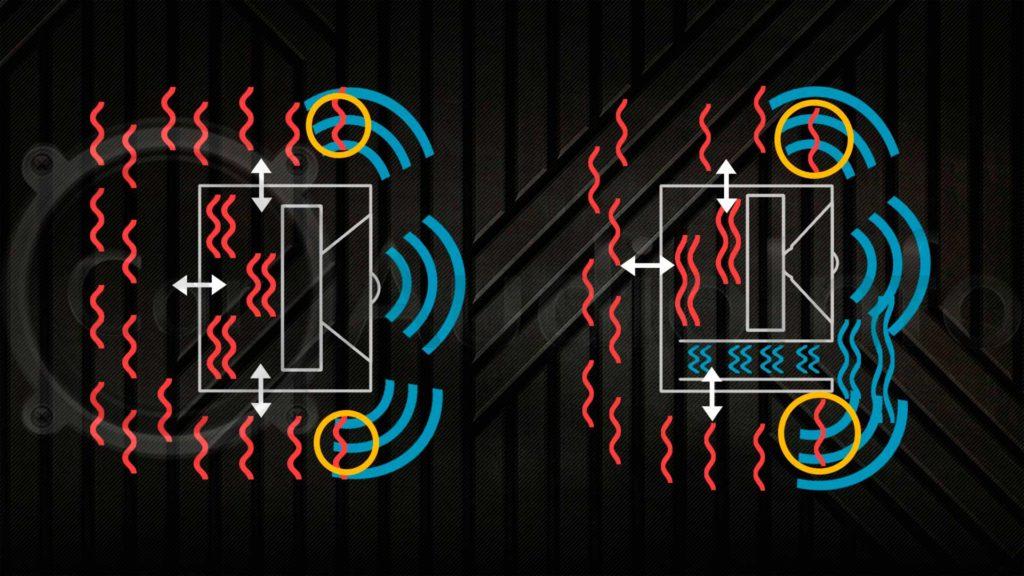

If we remove the speakers from the box of a working subwoofer, we will find that the bass that it reproduced with high quality will disappear. That is, a subwoofer without a box (acoustic design) does not play! Why is this happening? The subwoofer creates sound vibrations in both directions, i.e. forward and backward. If there is no screen between these sides, the sound vibrations cancel each other out. But if we put the subwoofer speakers in a closed box, we can separate the front and back of the subwoofer and get high-quality sound. By the way, in a phase inverter, the box works on a slightly different principle, it reproduces sound in one direction, which increases the volume compared to Z / Z by about 2 times.

How subwoofer boxes work

You say, why do we need this dregs with frequencies, waves and boxes? The answer is simple, we want to clearly and simply demonstrate to you how the material from which the box is made affects the quality of the final result.

What happens if the box is made of poor quality material

Now let's imagine that you made a box from your grandmother's wardrobe, that is, you used chipboard material, which is only 15 mm thick. After that, a medium-power subwoofer was made from it. What will be the result?

Due to insufficient wall thickness, the rigidity of the box is underestimated. When sound is played, the walls of the box begin to vibrate, i.e. the entire box turns into a radiator, the sound waves that the box resonates, in turn, dampen the waves that the speaker emits from the front side.

Remember, we said that a subwoofer speaker without a box simply cannot reproduce bass. So a low-rigid box will create only partial shielding, which will not be able to completely keep the interpenetration of sound waves emitted by the subwoofer speakers. As a result, the level of output power is reduced and the sound is distorted.

What should be a subwoofer box

The answer is simple. The main requirement that a subwoofer box must meet is its rigidity and strength. The stiffer the walls, the less vibration that the subwoofer creates during operation. Of course, in theory, a box made of ceramic plate or cast from lead with 15 cm walls would be considered ideal, but of course, this can be considered nonsense, since such subwoofers will have not only expensive production, but also huge weight.

Types and comparison of materials for a subwoofer.

Consider the real options for materials for the manufacture of a subwoofer and try to give a small conclusion on each of them.

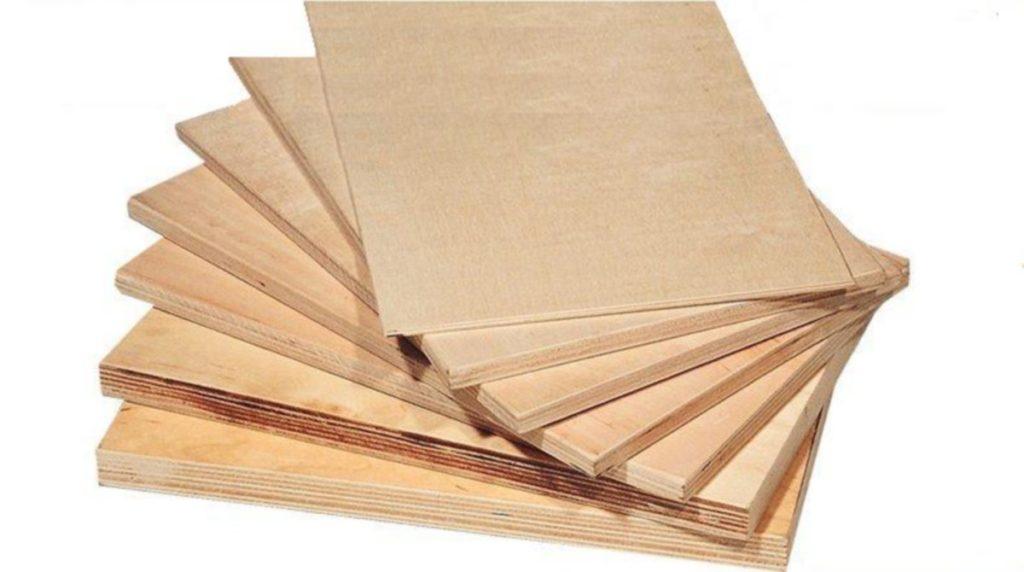

Plywood

Better moisture resistant. In our opinion, this is one of the most worthy materials for the manufacture of acoustic equipment.

But there are also a couple of downsides;

- This is the most expensive material.

- It is problematic to find plywood with a thickness of more than 18 mm.

- With a large area of \uXNUMXb\uXNUMXbthe walls, it starts to “ring” (additional stiffeners or spacers are needed)

MDF

Now gaining great popularity. It is a kind of gap between plywood and chipboard. Its main plus is the lower price than plywood (about the same as chipboard) good rigidity (but not up to plywood). Easy to saw. Moisture resistance is higher than that of chipboard.

- It is problematic, but possible to find a thickness of more than 18 mm.

Particleboard

Cheap, common material. There is in every furniture company, in the same companies you can order sawing. This box will cost you 2-3 times cheaper than plywood. Flaws:

- Very little rigidity of the material (an example about a grandmother's closet above).

- Not moisture resistant. It absorbs moisture well and crumbles. It is especially dangerous if water gets into your trunk.

How to increase the rigidity of the box?

- First, the simplest and most obvious. This is the thickness of the material, the thicker the material, the greater the stiffness. We advise you to use materials of at least 18 mm in the manufacture of a subwoofer, this is the golden mean. If your subwoofer has a power of more than 1500w RMS, then it will not be superfluous to choose a material thickness of 20 mm or more. If you are having difficulty finding thick-walled materials, you can use the following recommendations.

- An option that will add rigidity to your box is to make a double front wall. That is, the front part in which the speaker is installed. This part of the subwoofer is most exposed to stress during its operation. Therefore, having a material width of 18 mm, making the front wall double, we get 36 mm. This step will significantly add rigidity to the box. You should also do this provided that your subwoofer has an RMS (rated power) of more than 1500w. If you have a subwoofer for less power, for example, 700w, the front wall can also be made double. There is a sense in this, although the effect of such will not be very large.

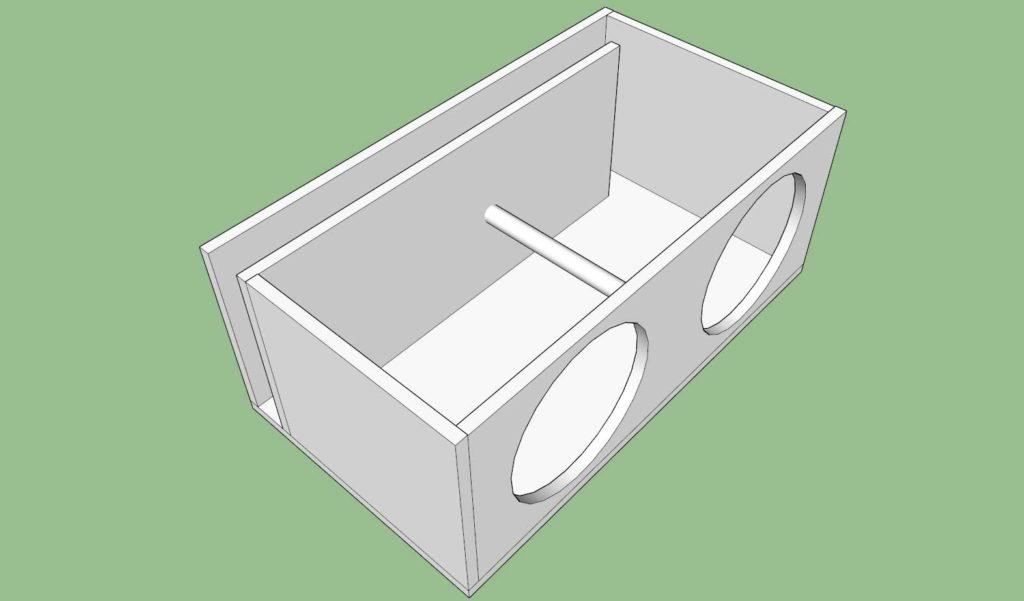

- Another tip, use spacers inside the subwoofer to add extra rigidity. This works especially well when the subwoofer has a large volume. Let's say you have two 12-inch subwoofers (speakers) in your box. In the middle, the rigidity of the box will be the smallest due to the large area. In this case, it will not hurt you to strengthen the structure and install a spacer in this place.

That's all we wanted to tell you about subwoofer materials. If this article helped you, rate it on a five-point scale below.

Do you want to try to calculate the box yourself? To do this, our article “Learning to count a box for a subwoofer” will help you.

Conclusion

We have put a lot of effort into creating this article, trying to write it in a simple and understandable language. But it is up to you to decide if we did it or not. If you still have questions, create a topic on the "Forum", we and our friendly community will discuss all the details and find the best answer to it.

And finally, do you want to help the project? Subscribe to our Facebook community.