How to choose the number of sandpaper for grinding cars

Content

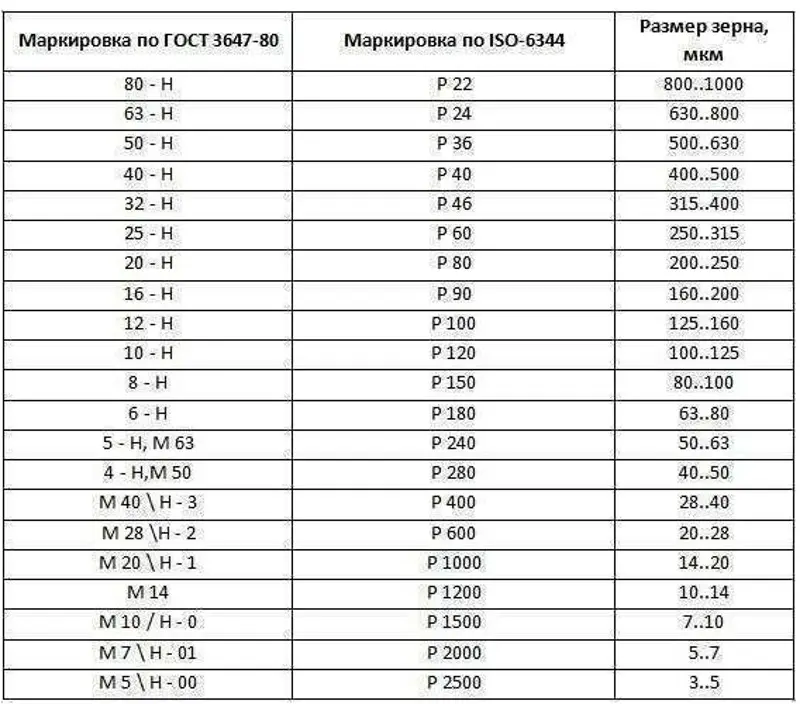

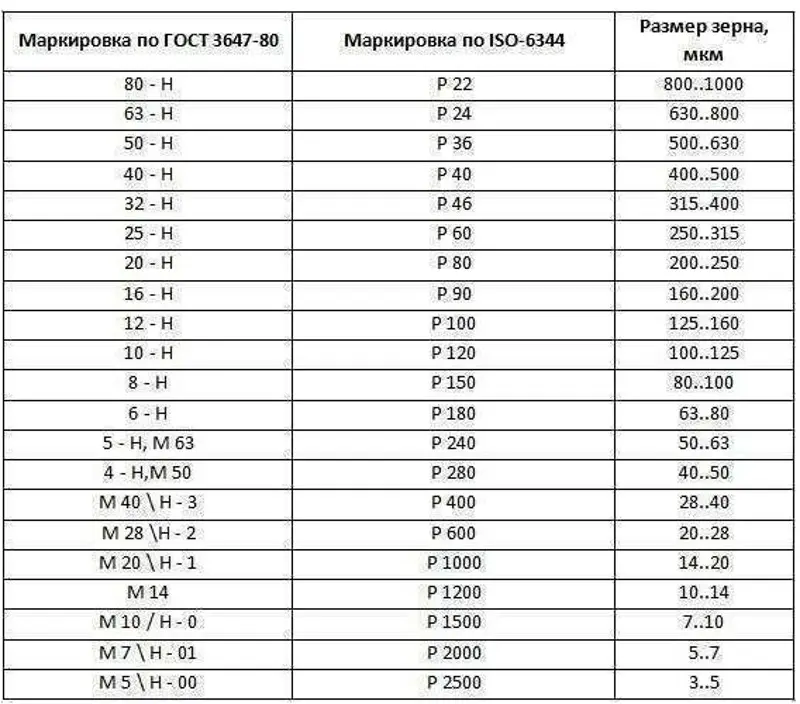

The reverse side of rolls, sheets or special grinding wheels is marked. It complies with Russian GOSTs of 1980 and 2005 (letter designation "M" or "H") and ISO international standardization standards (letter "P" in the marking).

Drivers who service their cars on their own are not even afraid of painting the body. A complex procedure, however, requires great knowledge, for example, what numbers of sandpaper are needed for painting, grinding, polishing a car. The topic is worth exploring.

Types of abrasive skins

Sandpaper (sandpaper) is a grinding material for giving a certain structure to the surface before painting and bringing it to shine and gloss after. Before you find out the number of sandpaper for painting a car, you need to understand the types of abrasive material. The division goes along the base, on which an abrasive is applied with glue or mastic.

There are the following types of skins:

- Paper. This is the most common and economical option, allowing you to apply very small chips on paper.

- Fabric-based. This sandpaper is more elastic and wear-resistant, which affects the price.

- Combined. The combination of the two previous options has absorbed the best properties: flexibility - from the fabric base, the possibility of applying fine abrasive - from the paper one.

Abrasive cloth on a cloth basis

Grain marking

"Grains" - abrasive powder - have different characteristics:

- the size;

- material of manufacture;

- application density per square inch.

These parameters help you choose the required number of sandpaper for polishing a car.

Grit is measured in micrometers (µm). The gradation of the emery material goes according to the particle size of the abrasive:

- Large. Numerical designation - from 12 to 80. Paper is used in rough preparatory work, primary processing of repaired areas. Large grain evens out chips, welds.

- Average. Designated by symbols from 80 to 160, it is used for fine-tuning body parts, final preparation for putty. From these indicators of granularity, the number of sandpaper for painting a car is chosen.

- Small. The largest amount of abrasive powder is concentrated on a square inch, ranging in size from 160 to 1400. Within these limits, there is a number of sandpaper for car polishing, which will be needed at the finishing stage of painting.

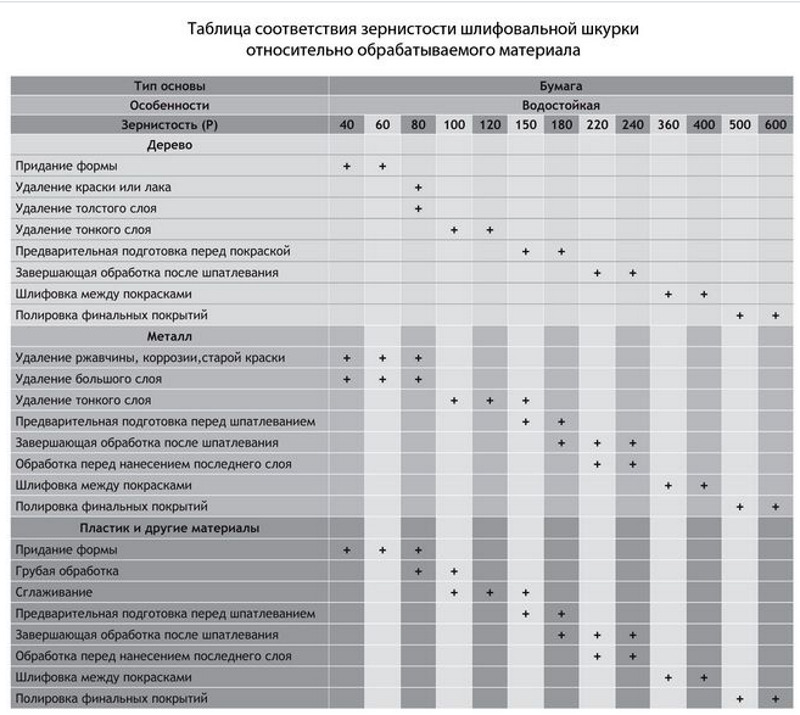

The photo shows a table of sanding grits for different materials.

Sanding grit table for different materials

The table shows that the numbers of sandpaper for stripping after puttying the car lie in the range from 180 to 240.

The reverse side of rolls, sheets or special grinding wheels is marked.

Sandpaper marking

It complies with Russian GOSTs of 1980 and 2005 (letter designation "M" or "H") and ISO international standardization standards (letter "P" in the marking).

Used abrasives

As a crumb (powder) for the base, manufacturers use stones, sand, shell rock and artificial polymer materials.

Popular abrasives:

- Garnet. Natural origin gives softness and elasticity to emery, which is often used for wood processing.

- Silicon carbide. A common universal powder for working with paintwork, metal surfaces.

- Ceramic crumb. A very strong material is needed for the formation of products.

- Zircon corundum. Resistant abrasive is often made in the form of a belt for grinders.

- Alumina. The durability of the abrasive allows it to be used for sharpening cutting edges.

Silicon Carbide Sandpaper

When choosing sandpaper numbers for painting cars, pay attention to silicon carbide abrasive.

How to sandpaper properly

The technology is simple. The main thing is accuracy and patience. For sanding, you need to take different numbers of sandpaper for painting a car - from the smallest to the largest grinding material.

Process Features

Work in a clean, dry, well-lit box. Do a wet cleaning, cover the floor and walls with plastic wrap.

Preparatory work

The final result of staining directly depends on the preparatory stage:

- Wash your car at a car wash first.

- In the garage, remove all plastic, chrome parts that are not related to painting.

- Wash the car again with shampoo, wipe dry, degrease with white spirit.

- Inspect the body, evaluate the scale of work. It is possible that not the entire area will have to be cleaned, painted and sanded.

- Brew the places that need it, straighten it.

Preparatory work

Then clean the room again.

Features of manual grinding

To facilitate the work, prepare a sanding pad in advance - a block with sandpaper holders. You can buy a device or make it yourself from improvised materials: a piece of wood, a hard sponge.

The first stage of stripping the body of car mechanics and painters is called matting. It is more convenient to polish over large areas using a grinder, but where the tool cannot crawl, it is better to rub it by hand. The number of sandpaper for matting a car is P220-240.

After this procedure, dents, scratches, and other defects are clearly exposed. Run the skin under the number P120: it will even out scratches, sharp edges of paint, clean up rust.

Sanding hand

The goal of the procedure at this stage is not a smooth surface. For better adhesion of putty with body metal, uniform micro-scratches should remain on the latter.

Don't forget to vacuum up the debris. When the surface is prepared, putty it, let it dry. Choose the right number of sandpaper for grinding after puttying the car, go through all the panels.

How to grind putty on a car with a grinder

The best result will be achieved with an eccentric orbital sander. The power tool is easy to use: you just need to attach special grinding wheels with mounting holes to the machine. Then drive along the surface in randomly selected directions.

The equipment is provided with a dust collector that sucks in the remnants of the abrasive. It is important to choose the right number of sandpaper and grain size for grinding the soil on a car, and the speed and quality will be provided by the device.

Sanding with a grinder

For the largest and smoothest areas, a belt sander will do. Attach sandpaper to it in the form of a canvas. Next, turn on the device and, holding the handle, drive it in the right direction. It is worth considering the power of the tool: the machine can grind off a large layer of metal.

A few extra tips

High-quality sanding is perhaps the main preparatory moment before staining. Here experience and intuition play a big role.

Tips from experienced car mechanics:

- If not the entire body needs to be sanded, cover the area near the repair area with masking tape.

- When scheduling restoration sites, do not be afraid to capture an area wider than the defect.

- Before sanding, treat the putty with a black developer: it will show where to add more putties.

- Always store and work with coarse, medium and fine grit skins.

- It is necessary to grind metal and putty with different physical effort: the primer layer is always softer and will simply be erased from excessive enthusiasm.

- Start with a coarse-grained sandpaper, then increase the number of sandpaper for car polishing by 80-100 units.

During operation, remove dust, do wet cleaning.