Which grinder to choose for a car

Content

An ideally adjusted body shape with even surfaces of a strictly specified variable curvature cannot be achieved during repairs without using grinding and polishing equipment. Manual labor is unproductive and requires special skills. Therefore, grinders of various designs and purposes are almost always used.

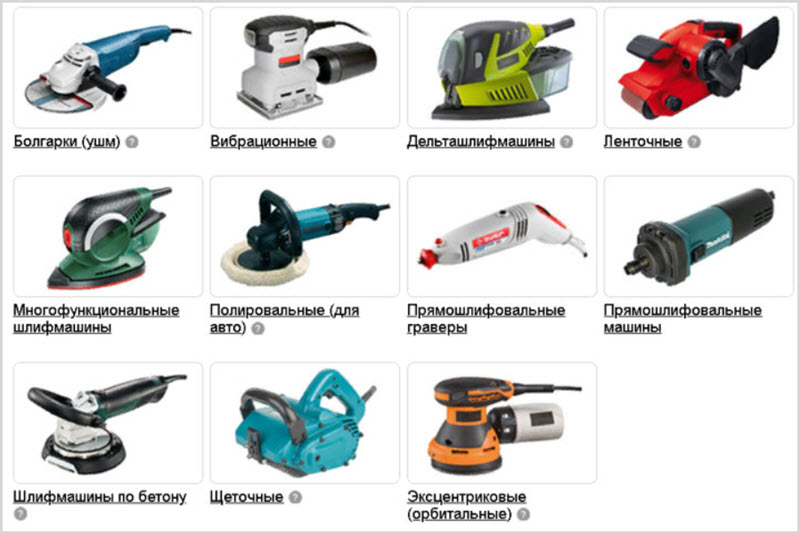

What grinders are for what?

Without knowing the features of the right choice, it is most likely impossible to obtain the required result. Theoretically, it is possible to get by with attachments for an electric drill, but this approach is unprofessional and leads to no less difficulties than grinding by hand.

Tape

The device contains an annular abrasive belt as a working unit. You can choose different grit and processing speed.

It is quite suitable for household grinding, for example, wooden parts, but it is not used in body repair due to a number of inconveniences:

- the canvas quickly clogs and loses its characteristics;

- consumables are unpopular, not designed to work with cars, do not last long and are relatively expensive;

- there are difficulties with neutralizing the influence of dust and other waste particles;

- it is difficult to regulate uniform pressure to the surface.

This technique can be used when high performance is needed. For cars, this is irrelevant.

Vibration

It looks more logical to attach a flat sheet of skin of the desired grain size to the vibrating sole of the machine.

Such machines are often used because they allow you to work more accurately, without the risk of spoiling the surface to be treated. But the productivity is low, although much higher than the manual method. It is convenient to work with fine finishing.

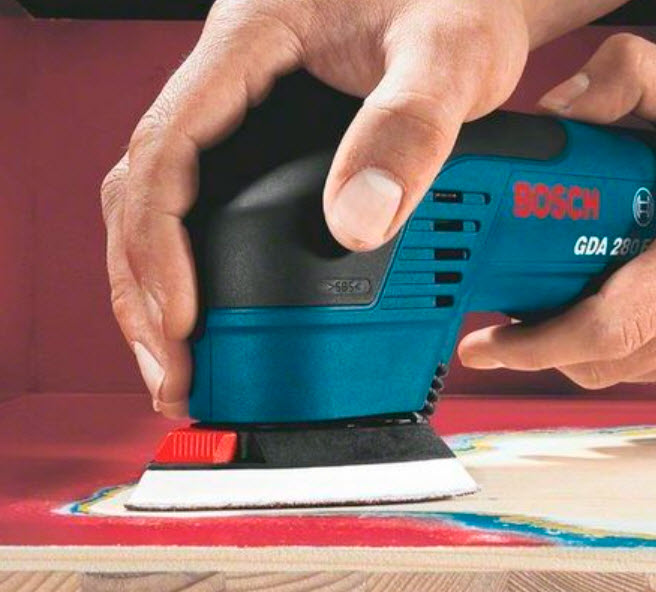

Eccentric

They are similar in principle to vibrating ones, but the working element moves along a more complex trajectory, which ensures an increase in productivity and an increase in surface quality.

Otherwise, the same can be said about this type as about the previous one.

Eccentric, they are also orbital machines with a round-shaped working element fixed on the sole, are divided into those working in a sector or combining the orbital reciprocating trajectory movement of the sole with rotational.

This allows you to get maximum efficiency in terms of a set of qualities. Rotation gives speed and sharpness of work, and orbitality - high purity and a minimum level of risks.

The properties of these, perhaps the best devices at the moment, are highly dependent on the magnitude of the stroke of the eccentric. And the best samples allow you not to change the machine depending on the working conditions, but to change the course with a simple switch. This achieves the versatility and well-deserved reputation of this type of machine.

They can be used in Random Orbit with adjustable frequency and eccentric stroke for all applications, from amateur to the most professional.

delta grinding

A variety of vibration and eccentric, but more adapted to work in places of difficult accessibility due to the shape of the sole with a point, like an iron. It is possible to process small areas that are difficult to approach with a rectangular soleplate.

Straight and brushed

For rough processing, you can use machines with a working element in the form of a carbide cutter with a fine notch, as well as a metal brush. A flat surface cannot be obtained with such a tool, but this is not always required.

For example, a straight machine works at a very high speed and even with a small diameter cutter quickly removes metal in hard-to-reach places where the classic angle technique with an abrasive disc cannot cope.

A brush is indispensable for processing contaminated and oxidized surfaces to bare metal, while not damaging the base itself. To a certain extent, it competes with the best cleaning method - sandblasting.

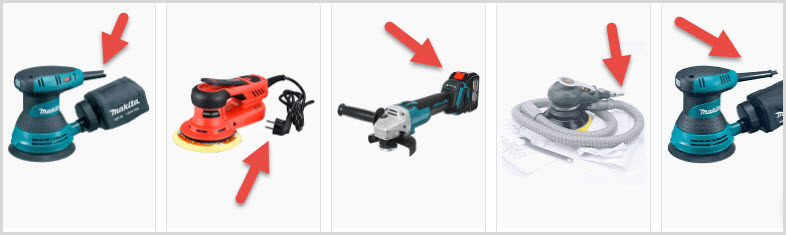

Source of power

Energy to the working element can come from compressed air, batteries or industrial AC power.

Pneumatic (air)

Pneumatic tools are popular in car service enterprises, since there is always a compressed air network fed by a common powerful compressor with a large receiver.

The pneumatic actuator is compact and powerful, which cannot be said about the sources of compressed air.

For the required performance, they must be expensive and bulky, as well as be equipped with additional devices for drying compressed air and supplying lubricant to the tool.

At the same time, they work very noisily. The use of pneumatic grinders in an amateur garage is hard to justify.

Mains powered

The most common source of energy for private use. The power cord can create some inconvenience, but this is not critical. But this technique is reliable, allows you to use additional functions, provides good power and is inexpensive.

Battery

The direction of autonomous power supply of power tools is rapidly developing due to the emergence of light and powerful batteries of significant capacity. Such a tool is the future, even now it is widely used, including by professionals.

But while mobile devices are expensive and need frequent charging. The latter does not cause inconvenience for amateurs, they will always find time to replenish energy. Therefore, you can save money by using a less capacious battery, which greatly affects the price of the tool.

How to choose a grinder for grinding and polishing a car

You can use an angle grinder with a set of nozzles, circles and a wide range of rotation speed adjustment as the simplest main and only tool.

In this case, a change in speed should not affect the power, that is, with a decrease in the number of revolutions, the torque should increase. This is achieved by complex electronic regulation and mechanical gear shifting.

But this option has significant limitations. The angle grinder is still more intended for cutting and rough grinding of metals, and the use for grinding in bodywork and painting will require considerable experience, special nozzles and consumables. Therefore, orbital, they are also eccentric machines, received the greatest popularity.

Such a device, combining rotation with a conditionally chaotic cyclic displacement, especially if switching the eccentric stroke is provided, will give both speed and purity of processing. Can be sanded coarsely or finely, as well as perfectly smooth polished. No wonder such devices are used as often as possible as a single tool.

Usage Basics

It’s not enough to have a tool, you need to know how to use it. Especially if it belongs to the category of universal, and not purchased in large quantities with a narrow specialization in certain types of work.

How to sand car body

Grinding is mainly used for processing metal irregularities, cleaning it from old coatings and rust, as well as for leveling the putty surface of the body.

In all cases, different nozzles are used, from abrasive discs working at the edge of a circle to flat circles with emery cloth applied to the end, both flat and in the form of sector petals. It all depends on the speed and purity of processing.

Watch this video on YouTube

First, the welding seams are cleaned with an abrasive and the parts are adjusted. These operations are similar to metal cutting, but thicker discs are used. Then, with an end disk, the surface is leveled with metal or putty.

Discs have different grain sizes for gradual removal of scratches and finishing under primer and paint. The discs are usually wetted with water, which prevents clogging of the abrasive, reduces the risk of deep scratches and reduces dusting.

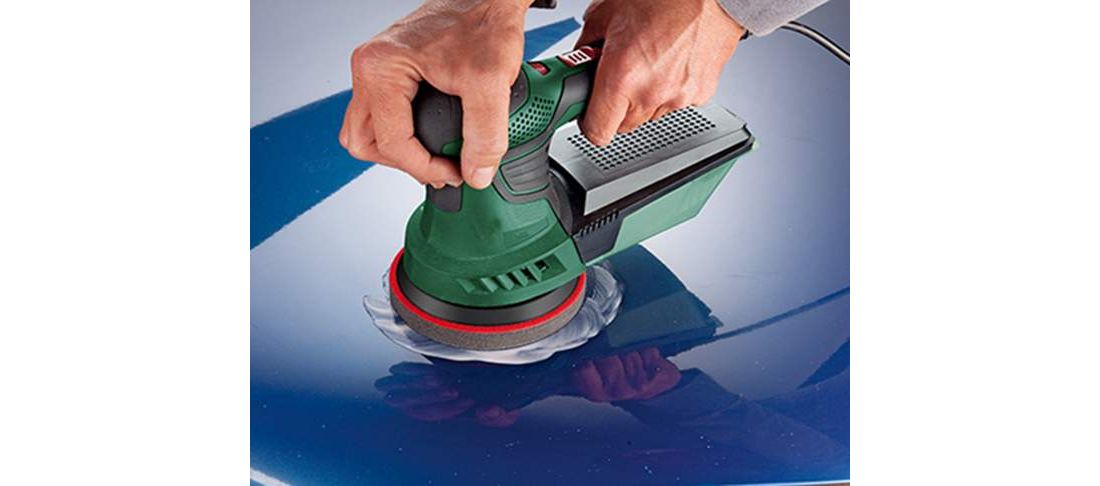

Polishing parts after painting

When polishing, it is important to choose the correct spindle speed and polishing paste number. They operate at a speed of about 500-800 per minute, which reduces the risk of overheating of paint or varnish and the likelihood of errors, which is very accurately called "digging holes."

Watch this video on YouTube

The number of paste gradually decreases from draft, which removes rough shagreen and flaws in the work of the spray gun, to the finish, which provides a mirror gloss.

Properly selected pastes eliminate the need to use felt and similar nozzles for final finishing.