What soundproofing for the car to choose

Content

What soundproofing for the car to choose? This question is asked by many car owners who, while driving, encounter serious noise in the cabin of their car. There are several types of insulation materials that eliminate noise - noise-absorbing, noise-isolating and vibration-isolating. Which material is better depends on the specific goal. Typically, soundproofing materials are applied to the floor of the car, on doors, on creaking plastic products. To enhance the effect, in some cases, a special liquid sound insulation is used, applied to the outer surface of the bottom and wheel arches of the car.

On the shelves of car dealerships there are many noise-insulating materials for the car interior. However, what kind of soundproofing for a car to choose? At the end of this material, a rating of good sound insulation is presented, which is widely used by domestic drivers. the list is not compiled for advertising purposes, but only on the basis of reviews and tests found on the Internet.

Why you need soundproofing

In fact, it is worth using soundproofing materials even on fairly expensive and high-quality foreign cars, not to mention budget domestic cars. There are three main reasons for this:

- Increase driving safety. Many people know that a prolonged unpleasant (and even louder) sound is deposited in the human subconscious, which leads to irritation of the nervous system. This, of course, applies to the driver. If he constantly drives in conditions when an unpleasant rumble is heard from the outside, the sounds of an internal combustion engine are heard from passing cars, plastic constantly creaks inside the car - the driver begins to involuntarily be distracted from the driving process, which can lead to an emergency on the road.

- Ride comfort. Reducing the noise in the car interior leads to the fact that driving in it becomes more comfortable. Fatigue is automatically reduced and the driver enjoys driving more. Similar reasoning is valid for passengers in the car.

- Additional reasons. These include, namely, the protective function. So, noise-insulating materials can protect the surface of doors and / or from mechanical damage and the occurrence of corrosion centers on them. also mentioned materials allow to stabilize the temperature inside the cabin. namely, to keep cool from the air conditioner in summer and warm from the stove in winter.

However, here it must be added that one should not be overly carried away by increasing the degree of sound insulation. Otherwise, there is a risk of not hearing a sound signaling a partial or complete failure of individual elements of the chassis, transmission, internal combustion engine and other things.

Hum in the car

Have you noticed that sometimes there is a hum in your car when driving, at idle, or when braking? There are quite a few reasons for this, and not all of them are related to the chassis (bearing) or... Read more

Therefore, good sound insulation should not be absolute. In addition, soundproofing pretty much adds you to the car, about 40-80 kg., And this already affects fuel consumption and acceleration.

also one case when good vibration and noise isolation is used is the use of a high-quality and powerful audio system in the car. As for sound insulation, it is natural that when listening to music, extraneous sounds from the outside should not reach the salon. And it will be unpleasant for people around you to hear very loud music from the passenger compartment of a passing car.

As for vibration isolation, it is needed, since during the operation of the speakers, the car body and its individual elements will vibrate, which can also cause unpleasant sounds. Moreover, the thicker (higher quality) the metal of the car body, the thicker the vibration isolation material is selected to dampen vibration. On tuned cars with powerful audio systems, special expensive insulating materials are installed.

Soundproofing materials

To perform the above tasks facing sound insulation, three types of materials are used:

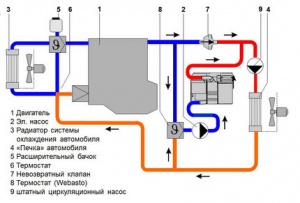

- Vibration isolation. Usually made on the basis of rubber rubber (similar to liquid rubber). The material is laid first, since its task is to dampen vibrations coming from the internal combustion engine, suspension, transmission. They are called "vibroplast", "bimast", "isoplast".

- Noise isolation. They, in turn, are divided into soundproofing and sound-absorbing. The task of the first is to reflect sound waves, to prevent them from getting inside the cabin. The task of the latter is to absorb and level these same sound waves. second layer material. In stores, they are sold under the name "bitoplast", "madeleine" or "biplast".

- Universal. They combine the functions of the materials listed above, and consist of two layers. Often, it is universal noise-vibration insulation materials that are used for sound insulation due to the fact that their installation is easier and faster. Their only drawback is their greater weight compared to the first two, which leads to an increase in fuel consumption.

car soundproofing material

Basic materials for car sound insulation. 4 steps to eliminate noise in the car interior. Self-made sound insulation for cars and materials for it. More details

What is the best car soundproofing?

The use of certain materials depends on the tasks assigned to them. For example, in some cases, the vibration isolation material is not laid in whole sheets, but only in strips. This reduces the efficiency of its work, however, reduces its mass, since in reality it is quite large. To do so or not is up to the owner to decide. As for soundproofing (sound-absorbing) materials, they must be laid in their entirety. Since the universal material cannot be divided into two layers, this leads to an increase in the total mass of the car.

As for the vibration isolation material, its large mass is due to the presence of bitumen in its composition. Remember that with the complete processing of the bottom, doors, wheel arches of the car body, its weight can increase by 50 ... 70 kilograms. Fuel consumption increases in this case by approximately 2 ... 2,5%. At the same time, the dynamic characteristics of the car are reduced - it accelerates worse, pulls uphill worse. And if for cars with relatively powerful internal combustion engines this does not present any particular difficulties, then, for example, for urban small cars it will be a very tangible factor.

How to choose soundproofing

A large selection of noise and vibration insulation materials makes us think about how to choose the right sound insulation. Regardless of this or that brand, a car enthusiast, when choosing, should always pay attention to the following reasons for the proposed product:

- Specific weight. In theory, the larger it is, the better the insulating material dampens vibrations and sounds coming from it. However, in reality this is not always the case. Currently, there are technological materials that dampen vibration due to their technical characteristics, namely, flexibility and the internal design of the fibers. But buying very light formulations is still not worth it, their effectiveness will be low. It is believed that the reinforced (aluminum) layer of vibration isolation material must be at least 0,1 mm thick. Nevertheless, a large change in its thickness in the direction of increase gives a small efficiency in terms of vibration isolation with a significant complication of installation and an increase in price.

- Mechanical Loss Factor (LLO). This is a relative value, which is measured as a percentage. In theory, the higher this figure, the better. Usually it is in the region of 10 ... 50%. A similar value that characterizes the absorption of sound waves is called the sound loss factor (SFC). The logic is the same here. That is, the higher this indicator, the better. The range of the mentioned value for goods sold in stores is also in the region of 10 ... 50%.

The two listed parameters are key, and often decisive in the matter of buying one or another vibration and noise insulation for a car. However, in addition to them, you also need to pay attention to the following additional reasons:

- Flexibility. This factor determines how well the material will adhere well and tightly to the treated surface of the car body.

- Ease of installation. namely, the choice of separately noise-proof and vibration-proof materials or one universal one. we are also talking about additional tools and materials - a building hair dryer, a roller, and so on. The issue of installation is also important from the point of view of economy. After all, if it is possible to install soundproofing material yourself, then this will save money. Otherwise, you will have to use the services of the appropriate masters at the service station.

- Durability. Naturally, the more impressive this indicator, the better. In this vein, it is worth reading the information about the warranty period in the instructions. it would also not be superfluous to ask the opinion of motorists who have already used one or another sound insulation for its durability.

- Resistance to mechanical damage. Ideally, it should not change its properties, including its shape, during the entire service life. However, usually sound insulation is mounted in places where it is not afraid of mechanical deformation.

- Material thickness. Depending on this, different sound insulation can be used not only for gluing large areas on the body, but also for processing small joints, for example, between rubbing plastic surfaces, which emit an unpleasant creak during friction.

- The quality of the mask. In this case, we are talking not only about its vibration and noise insulation characteristics. For some cheap low-quality materials, during installation, a situation is observed when the mastic flows out of the sheet under the influence of hot air and spreads over the surface to be treated. It is better not to buy such materials.

- Value for money. This factor is important, as in the choice of any other product. If you plan to process an inexpensive domestic car operated on bad roads, then there is no point in spending money on expensive insulation. And if we are talking about processing a foreign car from the middle price range, then it is better to choose a material that is more expensive and of better quality.

An important indicator when choosing is adhesion. In accordance with the definition, this is the adhesion of surfaces of dissimilar solid and/or liquid bodies. In the case of fastening, it refers to the force with which the insulating material is attached to the machined surface. Manufacturers in the documentation indicate this value, but some of them deliberately mislead car owners. The optimal adhesion value for fastening vibration and noise insulation is about 5…6 Newton per square centimeter. If the instructions indicate a value that is much higher than the one mentioned, then most likely this is just a marketing ploy. In fact, these values are quite sufficient for high-quality attachment of the material.

And of course, the most important factor in choosing one or another soundproofing for a car is the brand (company) under which it was produced. The most famous manufacturers whose products are ubiquitous in the post-Soviet space are STP, Shumoff, Kics, Dynamat and others. Each of the listed companies produces several lines of vibration and noise insulation.

Rating of soundproofing materials for cars

Here is a list of popular soundproofing for cars, based on the reviews of individual motorists found on the Internet, as well as on the volume of products sold by specialized online stores. The rating is not of a commercial nature. the basic task is to answer the question of how to choose soundproofing for a car.

STP

Under the STP trademark, some of the best and highest quality vibration and noise insulation materials are sold. The STP trademark belongs to the Russian group of companies Standardplast. Several types of these materials are produced. Let's list them in order.

STP Vibroplast

One of the most popular materials with which drivers and craftsmen protect the body and interior of the car from vibration. The line consists of four samples - Vibroplast M1, Vibroplast M2, Vibroplast Silver, Vibroplast Gold. The technical characteristics of each of the listed materials are summarized in the table.

| Material name | Specifications declared by the manufacturer | Real characteristics | |||

|---|---|---|---|---|---|

| Specific gravity, kg/m² | Thickness mm | KMP, % | Specific gravity, kg/m² | Thickness mm | |

| STP Vibroplast M1 | 2,2 | 1,8 | 20 | 3,0 | 1,7 |

| STP Vibroplast M2 | 3,1 | 2,3 | 25 | 3,6 | 2,3 |

| STP Vibroplast Silver | 3,0 | 2,0 | 25 | 3,1 | 2,0 |

| STP Vibroplast Gold | 4,0 | 2,3 | 33 | 4,1 | 3,0 |

The most popular material is Vibroplast M1 due to its low cost. However, its effectiveness is manifested only on thin metal. So, it will show itself well on domestic cars, but on foreign cars, in which, usually, the body is made of thicker metal, it will be ineffective. The instructions indicate that sheets of material can be glued to the following parts of the car body: metal surfaces of doors, roof, hood, passenger compartment floor, trunk bottom.

The Vibroplast M1 material is sold in sheets measuring 530 by 750 mm, and the thickness of the aluminum layer is optimal 0,1 mm. The price of one sheet as of spring 2019 is about 250 Russian rubles. The Vibroplast M2 modification is a more advanced version. It is slightly thicker, and has a higher mechanical loss coefficient. The two mentioned options relate to the budget segment of the market. Vibroplast M2 is sold in similar sheets measuring 530 x 750 mm. However, its price is slightly higher, and is about 300 rubles for the same period.

Vibroplast Silver and Vibroplast Gold materials already belong to the premium segment of the market for vibration and noise insulation materials. The first one is an improved version of Vibroplast M2 with similar characteristics. As for Vibroplast Gold, this is the most perfect material in this line. It has changed the embossing of the foil surface. This allows for easier installation on complex surfaces. Accordingly, the installation of Vibroplast Gold material can be carried out even in garage conditions.

The natural disadvantage of this product is only its relatively high price. So, the material "Vibroplast Silver" is sold in sheets of the same size 530 by 750 mm. The price of one sheet is about 350 rubles. Material "Vibroplast Gold" costs about 400 rubles per sheet.

STP Bimast

The materials included in the STP Bimast series are multi-layered, and are made of butyl rubber resin, bituminous plate, as well as auxiliary coatings. These materials are already effective on thicker metal, so they can also be used on bodies of foreign cars. The STP Bimast product line includes four materials. Their characteristics are shown in the table below.

| Material name | Specifications declared by the manufacturer | Real characteristics | |||

|---|---|---|---|---|---|

| Specific gravity, kg/m² | Thickness mm | KMP, % | Specific gravity, kg/m² | Thickness mm | |

| STP Bimast Standard | 4,2 | 3,0 | 24 | 4,3 | 3,0 |

| STP Bimast Super | 5,8 | 4,0 | 30 | 5,9 | 4,0 |

| STP Bimast Bomb | 6,0 | 4,0 | 40 | 6,4 | 4,2 |

| STP Bimast Bomb Premium | 5,6 | 4,2 | 60 | 5,7 | 4,3 |

STP Bimast Standart is the simplest and cheapest vibration and noise isolation material from this line. It has average noise and vibration reduction characteristics, but it can be used on any passenger car. However, its significant drawback is that when it is rolled out (installed) on the surface it processes, it rolls into lumps. it is also sometimes noted that it is short-lived and does not adhere well to the protective layer (it may peel off over time). "Bimast Standard" is implemented in the same dimensions, namely in pieces 530 by 750 mm. The price of one sheet as of spring 2019 is about 300 rubles.

Noise isolation STP Bimast Super is a more advanced version of the previous composition. On one side, foil paper is applied on the sheet. The material has increased thickness and mass. Therefore, it can be used on cases with wider metal. However, due to the greater mass, in some cases there is difficulty in installations. The thickness of the STP Bimast Standard is enough even to strengthen it on the bottom of the car body.

Among the shortcomings, it is noted that sometimes, during installation on areas of complex design, the foil layer may peel off. Therefore, the installation of the material must be carried out carefully or delegate this event to professionals. Soundproofing "Bimast Super" is implemented in the same sheets measuring 530 by 750 mm. The price of one sheet as of the above period is about 350 rubles.

The insulating material STP Bimast Bomb is the best material in the line in terms of price and quality. It has excellent characteristics, and it can be mounted both on the body of cheap domestic cars and on expensive foreign cars. It has a mechanical loss coefficient of 40%. Usually the material is of very high quality, but recently there has been a hit of defective products, in which the foil layer peels off over time or during installation.

Soundproofing "Bimast Bomb" is sold in similar sheets measuring 530 by 750 mm. The price of one sheet is about 320 rubles, which is a very favorable indicator for a material with its characteristics.

Well, the STP Bimast Bomb Premium soundproofing is the material with the highest technical performance in this line. Its mechanical loss coefficient is as much as 60%! With its help, you can isolate the doors, bottom, trunk lid, hood and other areas on the car body. The material is of very high quality, however, due to the large mass, it is sometimes difficult to mount it, especially in areas with a complex structure. The only drawback of Bimast Bomb Premium soundproofing is the high price.

Sold in the same sheets measuring 750 by 530 mm. The price of one sheet is about 550 rubles.

STP Vizomat

The STP Vizomat line has been on the market for a long time, but is still popular. namely, they are used by owners of machines with a thick metal body. The line includes four materials. Their names and characteristics are summarized in the table.

| Material name | Specifications declared by the manufacturer | Real characteristics | |||

|---|---|---|---|---|---|

| Specific gravity, kg/m² | Thickness mm | KMP, % | Specific gravity, kg/m² | Thickness mm | |

| STP Vizomat PB-2 | 2,7 | 2,0 | 12 | 2,8 | 2,0 |

| STP Vizomat PB-3,5 | 4,7 | 3,5 | 19 | 4,7 | 3,5 |

| STP Vizomat MP | 3,8 | 2,7 | 28 | 4,0 | 2,8 |

| STP Vizomat Premium | 4,8 | 3,5 | 40 | 4,8 | 3,5 |

Soundproofing material STP Vizomat PB-2 is the simplest in the above line. It is fairly lightweight and easy to install. However, its disadvantage is poor performance in terms of noise and vibration isolation. Therefore, it can only be installed if a car enthusiast does not want to spend significant money on soundproofing the interior of his car.

Noise and vibration isolation "Vizomat PB-2" is produced and sold in the same dimensions, in sheets 530 by 750 mm. The price of one sheet as of the above period is about 250 rubles.

Noise isolation STP Vizomat PB-3,5 is a more advanced version of the previous material. So, it has a greater thickness and is able to better withstand vibration. Thus, its mechanical loss coefficient is increased to a value of 19%, but this is also a relatively small indicator. Thus, the materials "Vizomat PB-2" and "Vizomat PB-3,5" are budgetary and inefficient materials. In addition, it is indicated that it is undesirable to mount them on the roof of the car body and on the door panel. This is due to the fact that in hot weather the glue can soften and the material, respectively, completely or partially fall off. But they can be used, for example, to isolate the floor (bottom) of a machine body.

The price of one sheet of insulation "Vizomat PB-3,5" measuring 530 by 750 mm is about 270 rubles.

Noise isolation STP Vizomat MP is the most popular in this line. It combines good performance and low price. The material should be used on a car body made of thick metal, rigid structures. It is noted that the installation process is quite time-consuming, but the material keeps its shape perfectly and protects the body from vibrations and the interior from noise. Among the shortcomings, it is noted that in summer temperatures (namely, from + 28 ° C and above), the material softens, which leads to a decrease in damping properties. But it can be used, for example, to process the bottom, since it is unlikely to heat up to such a temperature.

Soundproofing "Vizomat MP" is produced in the same sheets 530 by 750 mm. The price of one such sheet is about 300 rubles.

Noise and vibration isolation STP Vizomat Premium is the most expensive and high-quality product in this line, since the coefficient of mechanical losses is increased up to 40% with a weight and thickness similar to Vizomat PB-3,5. Accordingly, Vizomat Premium soundproofing can be used on almost any body of cars and commercial vehicles. The only drawback of the material is its relatively high price.

The price of one standard sheet, having a size of 530 by 750 mm, is about 500 rubles for the above period.

STP NoiseLIQUIDator

The range of products manufactured by STP includes a vibration-damping two-component mastic STP NoiseLIQUIDator. It is positioned by the manufacturer as a liquid sound insulation, which has anti-corrosion and reinforcing properties. Mastic is applied to the bottom, sills and arches on the car body. At the same time, it is indicated that it is necessary to apply the composition to parts with a relief surface, and it is undesirable to apply it to smooth surfaces. so, this mastic will be a great addition to the STP soundproofing sheets described above. Characteristics of STP NoiseLIQUIDator mastic:

- the level of noise reduction in the cabin - up to 40% (up to 3 dB);

- mechanical loss coefficient (vibration reduction) - 20%;

- operating temperature range — from -30°С to +70°С.

The mastic is applied to the prepared (cleaned) surface with a spatula. Do not leave open packaging for a long time, as its composition may harden and become unusable. It is sold in a bank weighing one kilogram. The approximate price of one such package is about 700 rubles.

You off

In the range of Shumoff products manufactured by the Russian company Pleiada, there are two subspecies of such products - soundproofing materials with the effect of thermal insulation, as well as vibration-absorbing materials. Let's consider them separately.

Soundproofing materials

The range of soundproofing materials consists of six sound and heat insulating materials. their characteristics are given below.

- Comfort 10. Self-adhesive material based on black foam rubber. The mounting layer is protected by adhesive paper. The thickness of the material is 10 mm. Specific gravity - 0,55 kg / m². The size of one sheet is 750 by 1000 mm. Operating temperature range — from -45°С to +150°С. The price of one sheet as of the spring of 2019 is about 1200 Russian rubles.

- Comfort 6. A similar sound and heat insulating material, based on foamed rubber. The mounting layer is protected by adhesive paper. The thickness of the material is 6 mm. Specific gravity - 0,55 kg / m². The size of one sheet is 750 by 1000 mm. Operating temperature range — from -45°С to +150°С. The advantage is that the installation of the material is possible without the use of a building hair dryer at an ambient temperature of + 15 ° C and above. The price of one sheet is about 960 rubles.

- Shumoff P4. A similar material based on polyethylene foam with a closed cell structure and an adhesive layer. There is adhesive paper on the mounting side. The thickness of the material is 4 mm. Specific gravity - 0,25 kg / m². The size of one sheet is 750 by 560 mm. Operating temperature range — from -40°С to +110°С. The strength of the bond with the bearing surface is 5 N/cm². The price of one sheet is 175 rubles.

- Shumoff P4B. Sound and heat insulating material based on polyethylene foam with a closed-cell structure and a sticky layer applied on it. The mounting layer is protected by adhesive paper. The letter "B" in the designation indicates that a waterproof adhesive was used in the production of the material. The thickness of the material is 4 mm. Specific gravity - 0,25 kg / m². The size of one sheet is 750 by 560 mm. Operating temperature range — from -40°С to +110°С. The strength of the bond with the bearing surface is 5 N/cm². The price of one sheet is 230 rubles.

- Shumoff P8. Vibration isolation material based on polyethylene foam with a self-adhesive layer. There is adhesive paper on the mounting layer. The thickness of the material is 8 mm. Specific gravity - 0,45 kg / m². The size of one sheet is 750 by 560 mm. Operating temperature range — from -40°С to +110°С. The strength of the bond with the bearing surface is 5 N/cm². The price of one sheet is 290 rubles.

- Shumoff P8B. A similar noise and thermal insulation material based on foamed polyethylene with waterproof glue, as indicated by the letter "B" in the designation. There is adhesive paper on the mounting layer. The thickness of the material is 8 mm. Specific gravity - 0,45 kg / m². The size of one sheet is 750 by 560 mm. Operating temperature range — from -40°С to +110°С. The strength of the bond with the bearing surface is 5 N/cm². The price of one sheet is 335 rubles.

Any of the listed materials is recommended for isolating the cabin not only from noise impacts, but also in order to maintain a comfortable temperature in the cabin - cool in summer and warm in winter.

Vibration isolation materials

Vibration isolation materials are the basis for noise insulation of the car interior. Currently, the line of the Shumoff trademark is represented by 13 similar products that differ in their technical and operational characteristics.

- Shumoff M2 Ultra. The vibration isolation composition was developed to meet the requirements of the American material Dinamat. However, the latter costs about three times more than its Russian counterpart. In addition to dampening vibration, the material increases the overall rigidity of the body. The thickness of the material is 2 mm. The coefficient of mechanical losses is 30%. The foil thickness is 100 microns. Specific gravity - 3,2 kg / m². Sheet size - 370 by 270 mm. The maximum allowable operating temperature is +140°C. It is allowed to perform installation of the material at an ambient temperature of +15°C and above. The price of one sheet is about 145 rubles.

- Shumoff M2.7 Ultra. this material is completely similar to the previous one. The difference is only its thickness - 2,7 mm, as well as the specific gravity - 4,2 kg / m². can also be mounted without the use of a building hair dryer at temperatures from +15 degrees Celsius and above. The price of one sheet is about 180 rubles.

- Shumoff Light 2. It is a vibration-absorbing self-adhesive material with a low density mastic layer. On the front side there is aluminum foil, which provides mechanical protection of the material, as well as increases its vibroacoustic properties. The thickness of the material is 2,2 mm. The foil thickness is 100 microns. Specific gravity - 2,4 kg / m². Sheet size - 370 by 270 mm. Improves the rigidity of the car body. Operating temperature range — from -45°С to +120°С. Can be mounted without the use of a building hot air gun at an ambient temperature of +20°C and above. The price of one sheet is about 110 rubles.

- Shumoff Light 3. The material is completely similar to the previous one. It differs only in thickness, namely - 3,2 mm and specific gravity - 3,8 kg / m². The maximum allowable operating temperature is +140°С. Can be mounted without a hair dryer at a temperature of +15°C. The price of one sheet is 130 rubles.

- Shumoff Mix F. Vibration-absorbing self-adhesive material designed for installation on metal and plastic parts of the car. The front layer is aluminum foil. Next come several layers of different mastics. The last mounting layer is covered with adhesive paper. The thickness of the material is 4,5 mm. The foil thickness is 100 microns. Specific gravity - 6,7 kg / m². Sheet size - 370 by 270 mm. Improves the rigidity of the car body. Please note that for the installation of the material, it is necessary to use a building hair dryer, with which you need to heat it up to a temperature of + 50 ° C. The price of one sheet is about 190 rubles.

- Shumoff Mix F Special Edition. This material is one of the most popular in this line. In its structure and properties, it is completely similar to the previous one. However, it has better features. The thickness of the material is 5,9 mm. The foil thickness is 100 microns. Specific gravity - 9,5 kg / m². Sheet size - 370 by 270 mm. Improves the rigidity of the car body. Can be mounted without the use of a building hair dryer. The price of one sheet is about 250 rubles.

- Shumoff M2. One of the simplest, lightest and cheapest materials in this series. The front cover is aluminum foil. The self-adhesive side is coated with release paper. The thickness of the material is 2,2 mm. The foil thickness is 100 microns. Specific gravity - 3,2 kg / m². Sheet size - 370 by 270 mm. Improves the rigidity of the car body. The maximum allowable operating temperature is +140°C. Can be mounted without a hair dryer at a temperature of +15°C. The price of one sheet is 95 rubles.

- Shumoff M3. Completely similar to the previous material, but a little thicker. The thickness of the material is 3 mm. The foil thickness is 100 microns. Specific gravity - 4,5 kg / m². Sheet size - 370 by 270 mm. Improves the rigidity of the car body. The maximum allowable operating temperature is +140°С. Can be mounted without a hair dryer at a temperature of +15°C. The price of one sheet is 115 rubles.

- Shumoff M4. Completely similar to the previous material, but a little thicker. The thickness of the material is 4 mm. The foil thickness is 100 microns. Specific gravity - 6,75 kg / m². Sheet size - 370 by 270 mm. Improves the rigidity of the car body. The maximum allowable operating temperature is +140°С. Can be mounted without a hair dryer at a temperature of +15°C. The price of one sheet is 155 rubles.

- Shumoff Prof. F. Vibration damping thermoadhesive material of increased rigidity. Created on the basis of a highly filled bituminous polymer composite. It perfectly dampens even significant vibrations and strengthens the car body. The thickness of the material is 4 mm. The foil thickness is 100 microns. Specific gravity - 6,3 kg / m². Sheet size - 370 by 270 mm. Please note that this material is recommended for use in regions with constant positive temperatures. The instructions indicate that it is more effective at temperatures of + 40 ° C and above. During installation, it is necessary to use a building hair dryer in order to heat the material to a temperature of + 50 ° C. The price of one sheet is 140 rubles.

- Shumoff Layer. The material is a highly filled permanent tack polymer. It has two layers - mounting and masking. It has little efficiency, but it can be used in open places on the body. The thickness of the material is 1,7 mm. Specific gravity - 3,1 kg / m². Sheet size - 370 by 270 mm. Improves the rigidity of the car body. The maximum allowable operating temperature is +140°С. Can be mounted without using a building hair dryer. The price of one sheet is 70 rubles.

- Shumoff Joker. The vibration-absorbing material Shumoff Joker is a mastic with increased cohesive strength, penetration and adhesion properties. The great advantage of this material is its increased adhesion to steel and aluminum. Therefore, it can be used on any surface of the car body. The thickness of the material is 2 mm. The foil thickness is 100 microns. Specific gravity - 3,2 kg / m². Sheet size - 370 by 270 mm. Improves the rigidity of the car body. The maximum allowable operating temperature is +140°C. Can be mounted without a hair dryer at a temperature of +15°C. The price of one sheet is 150 rubles.

- Shumoff Joker Black. This material is completely similar to the previous one, but has a greater thickness. So, it is 2,7 mm, and the specific gravity, respectively, is 4,2 kg / m². The name Black (in English - “black”) was given to the material because of its design. The thin (2mm) Joker comes with a light background image, while the thick (2,7mm) Joker comes with a dark background. One sheet costs 190 rubles.

The developer of the listed vibration isolation materials, the Pleiada company, is constantly expanding the range of products. Therefore, there may be updates in the market.

KICX

Under the trademark KICX, sound-absorbing and vibration-absorbing materials are produced separately. Let's consider them separately.

Vibration absorbing materials

As of spring 2019, there are 12 different materials in the line, but only 5 of them are designed for installation in cars. Let us briefly present the names and characteristics of some of them:

- Optima. The latest addition to the lineup. The material is a lightweight foil vibration-absorbing composition. It is a rubber-based polymer composition. The size of one sheet is 270 by 370 mm. Sheet thickness - 1,6 mm. Suitable for installation on various elements of the car body. The product is sold in a package consisting of 30 sheets (total area is less than 3 square meters). The price of a package as of the above period is about 1500 rubles, which is quite inexpensive compared to analogues.

- Standard. Classic vibration isolation material for the car. The size of one sheet is 540 by 370 mm. Thickness - 2,1 mm. Specific gravity - 3,2 kg / m². The coefficient of mechanical losses is 26%. The bond strength with the surface is 10 N/cm². 26 sheets are packed in a pack, the total area is 4,6 m². The price of one pack is 2500 rubles.

- Super. this vibration isolation material can be used both for car noise isolation and for providing high-quality sound of any car audio systems. Differs in very high operational characteristics. Sheet size - 540 by 370 mm. Sheet thickness - 2,7 mm. The coefficient of mechanical losses is 34%. The force of attraction to the surface is 10 N/cm². Specific gravity - 4,6 kg / m². It is sold in a package containing 16 sheets, the total area is 3,2 m². The price of such a package is 2500 rubles.

- EXCLUSIVE. A good anti-vibration material to reduce noise in the car and/or to improve the sound of the audio system in the cabin. Sheet size - 750 by 500 m. Sheet thickness - 1,8 mm. The coefficient of mechanical losses is 23%. Adhesion strength - 10 N/cm². The package contains 15 sheets with a total area of 5,62 m². The price of one package is 2900 rubles.

- EXCLUSIVE EFFECT. An improved version of the previous material, suitable for installation in any car. Sheet size - 750 by 500 mm. Sheet thickness - 2,2 mm. The coefficient of mechanical losses is 35%. Adhesion strength - 10 N/cm². The package contains 10 sheets with a total area of 3,75 m². The price of one package is 2600 rubles.

Noise absorbing materials

There are seven products in the KICX line of noise-absorbing materials. However, for use in a car environment, it is best to use only two.

- SP13. This is an innovative soundproofing material based on a structured pyramidal surface. This form effectively absorbs the energy of the sound wave. The material is waterproof and sound-transparent. The size of one sheet is 750 by 1000 mm. Its thickness is 13 mm (which can cause difficulties with its installation in the cabin). The package contains 16 sheets with a total area of 12 square meters. The price is 950 rubles.

- Car FELT. Soundproofing material specially developed by the company for its installation in a car. Sheet size - 750 by 1000 mm. Thickness - 1 mm. The package contains 10 sheets, with a total area of 7,5 square meters. The price is 280 rubles.

Other brands

The manufacturers and brands listed above are the most popular. However, on the shelves of car dealerships you can find products of other brands. We list the most popular of them among domestic motorists.

Dynamat

- Dynamat 21100 DynaPad. Good sound insulation for the car interior. It has a sheet size of 137 by 81 cm. Accordingly, one sheet can be used for a large area of insulation. Sheet thickness - 11,48 mm. The metallized layer is absent. Reviews about the material are quite good. Therefore, it is recommended for purchase. The only drawback is the high cost. The price of one sheet as of the spring of 2019 is about 5900 rubles.

- Dynamat Xtreme Bulk Pack. Quite old, but effective material. Made from black butyl with aluminum sheet. Excellent adhesion to metal surfaces. The material can be used at temperatures from -10°C to +60°C. The mechanical loss coefficient is 41,7% at a temperature of +20 degrees Celsius. Installation of the material is not difficult, since the adhesive layer holds the sheet well, and the weight of the sheet is low. The price of one square meter of Dynamat Xtreme Bulk Pack is 700 rubles.

- Dynamat Dynaplate. Vibro- and noise-absorbing very plastic material. It has a very high insulating performance, and at the same time it is very thin and light. In addition to the car, it can also be used for installation in the pombinations. The mechanical loss coefficient depends on temperature. Among the shortcomings can be noted the complexity of installation and high cost. The price per square meter of material is about 3000 rubles.

Ultimate

Ultimate products are divided into several types, among which noise absorbers and vibration absorbers are offered separately. Consider them separately, let's start with noise absorbers.

- ULTIMATE SOUND ABSORBER 15. The material absorbs medium and high frequency sounds particularly well. Can be used for installation on doors, roof, motor shield from the passenger compartment, wheel arches. No smell, easy to install. It is recommended to install it together with vibration absorbing materials. The size of one sheet is 100 by 75 cm. The thickness of the sheet is 15 mm. The price of one sheet is 900 rubles.

- ULTIMATE SOUND ABSORBER 10. More technological material compared to the previous one. It is an elastic polyurethane foam modified with a special impregnation with a sticky layer protected by an anti-adhesive gasket. Waterproof durable material with increased resistance to ultraviolet radiation. Sheet size - 100 by 75 cm. Sheet thickness - 10 mm. The price is 900 rubles.

- ULTIMATE SOUND ABSORBER 5. Similar to the previous material, but with a smaller thickness. It has the worst performance, however, and is cheaper, therefore it is one of the most popular insulating materials among motorists. It can be used either for minor interior insulation, or in the case when, for some reason, thick material cannot be used. The sheet size is similar - 100 by 75 cm, thickness - 5 mm. The price of one sheet is 630 rubles.

- ULTIMATE SOFT A. The new development of the company, has a very high performance. The material is made on the basis of foamed rubber with increased elasticity. Combines the functions of vibration and noise absorber. Operating temperature range — from -40°С to +120°С. Sheet size - 50 by 75 cm. Thickness - 20 mm, which may limit its use in some machine shops. Noise reduction level — 90…93%. The only drawback is the high cost. The price for one sheet is about 1700 rubles.

The following is a range of ULTIMATE vibration absorbing materials.

- ULTIMATE CONSTRUCT A1. Vibration absorber based on improved polymer-rubber composition, backed with aluminum foil. Operating temperature range — from -40°С to +100°С. Sheet size - 50 by 75 cm. Thickness - 1,7 mm. Specific gravity - 2,7 kg / m². It can be installed on the car body floor, door, roof, body sides, hood and trunk lid, wheel arches. The coefficient of mechanical losses is 25%. The price of one sheet is 265 rubles.

- ULTIMATE CONSTRUCT A2. The material is completely similar to the previous one, but with a greater thickness. Sheet size - 50 by 75 cm. Sheet thickness - 2,3 mm. Specific gravity - 3,5 kg / m². The coefficient of mechanical losses is 30%. The price of one sheet is 305 rubles.

- ULTIMATE CONSTRUCT A3. Similar material with also greater thickness. Sheet size - 50 by 75 cm. Thickness - 3 mm. Specific gravity - 4,2 kg / m². The coefficient of mechanical losses is 36%. The price of one sheet is 360 rubles.

- ULTIMATE CONSTRUCT BLOCK 3. A new multilayer vibration absorber based on thermoset bitumen. The advantage is that at a temperature of +20°C ... +25°C and above, you can mount the material without heating. However, after installation, it is desirable to warm it up to a temperature of + 70 ° C in order to increase the rigidity of the material. The size of one sheet is 37 by 50 cm. Thickness is 3,6 mm. The coefficient of mechanical losses is 35%. The price of one sheet is 240 rubles.

- ULTIMATE CONSTRUCT BLOCK 4. The material is similar to the previous one, but with better characteristics. Sheet size - 37 by 50 cm. Thickness - 3,4 mm. The coefficient of mechanical losses is 45%. The price of the sheet is 310 rubles.

- СONSTRUCT B2. This is one of the cheapest, but also inefficient materials in the line. It is recommended to use on metal surfaces up to 0,8 mm thick. It is made on the basis of thermosetting bitumen. It must be mounted when heated to + 30 ° С ... + 40 ° С. And then heat up to +60°С…+70°С to increase the rigidity of the material. Sheet size - 750 by 500 mm. Thickness - 2 mm. Specific gravity - 3,6 kg / m². Acoustic noise reduction - 75%. The price of one sheet is 215 rubles.

- СONSTRUCT B3,5. The material is similar to the previous one. Recommended for use on metal surfaces with metal thickness up to 1 mm. Sheet size - 750 by 500 mm. Sheet thickness - 3,5 mm. Specific gravity - 6,1 kg / m². Acoustic noise reduction - 80%. The price of one sheet is 280 rubles.

In fact, this list is far from complete. Many manufacturers are intensively conducting relevant research and introducing new models of vibration and noise isolation into production. Therefore, the range of online stores and regular trading platforms is constantly updated. Have you used vibration isolation, and if so, which one? Tell us about it in the comments.

Hack and predictor Aviator

Noise isolation allows not only to get rid of unpleasant sounds, but also to provide comfort for the driver and passengers while driving. Therefore, if the car is not equipped with even a minimal soundproofing package, it is advisable to fix it. At the same time, you need to understand that some sounds coming into the cabin from the outside can signal a breakdown of individual vehicle suspension components, its internal combustion engine, and transmission. Therefore, isolation does not have to be absolute. As for the choice of this or that soundproofing material, its choice should be based on the noise level, the presence of vibration, ease of installation, durability, value for money. However, the materials listed above are already used by car owners, so they are highly recommended for installation on your car.