When is the right time to grind a brake disc?

Content

Stuttering, jerky brakes can be associated with undulating brake disc wear. This does not necessarily require a new set of brake discs. Under certain circumstances, brake discs can be made fully functional with a simple, quick and cheap solution.

Each braking maneuver places a high load on the material, which always causes some abrasion. As a result, the brake discs may wear unevenly with potentially fatal consequences: the braking distance is lengthened, and during sudden braking, the vibrations of the car and the steering wheel are clearly felt .

Why grind a brake disc?

To grind or not to grind is not a question, but a simple equation:

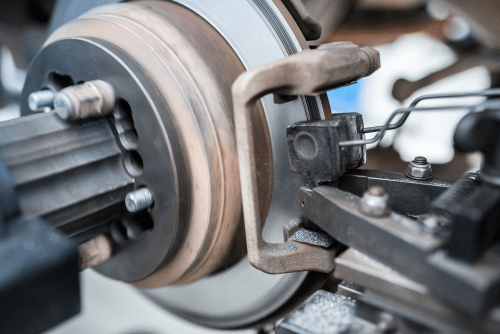

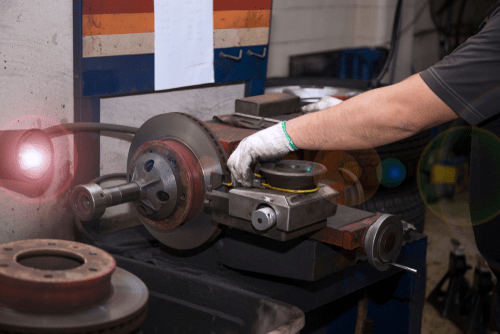

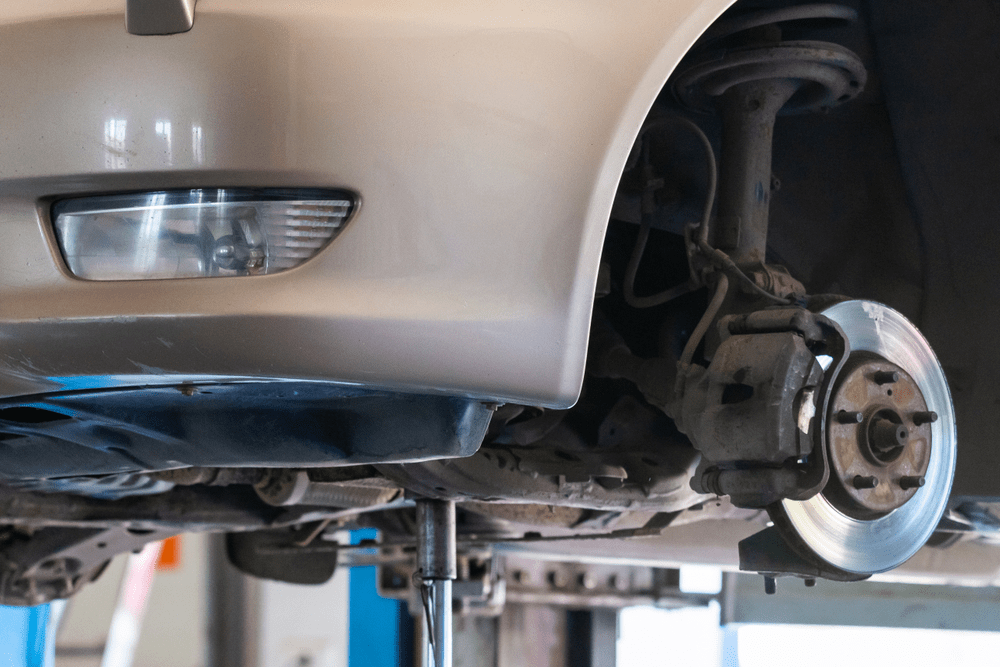

For grinding brake disc disassembly is not required. Workshops offering this service usually have necessary equipment , which allows you to process brake discs without having to remove them.

You only need to remove the wheel and brake caliper . Professional surface grinder approx. 10 euros, however the service charge starts from 50 euro . Even the cheapest brake discs cannot compete with this, not to mention the additional replacement fee.

Depending on the type of car, a new set of brake discs can get very expensive. ... IN compact и family cars plain brake discs available at a price of 60 euros (± 53 pounds sterling) per set For heavy cars with high power new brake discs can cost you several hundred pounds. Therefore, grinding deserves attention for repairable damage to brake discs. .

Repairable brake disc damage

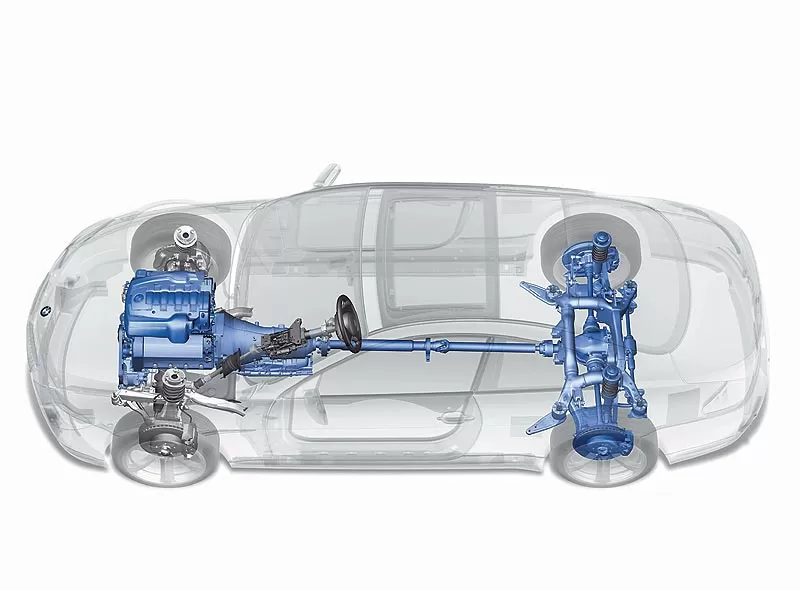

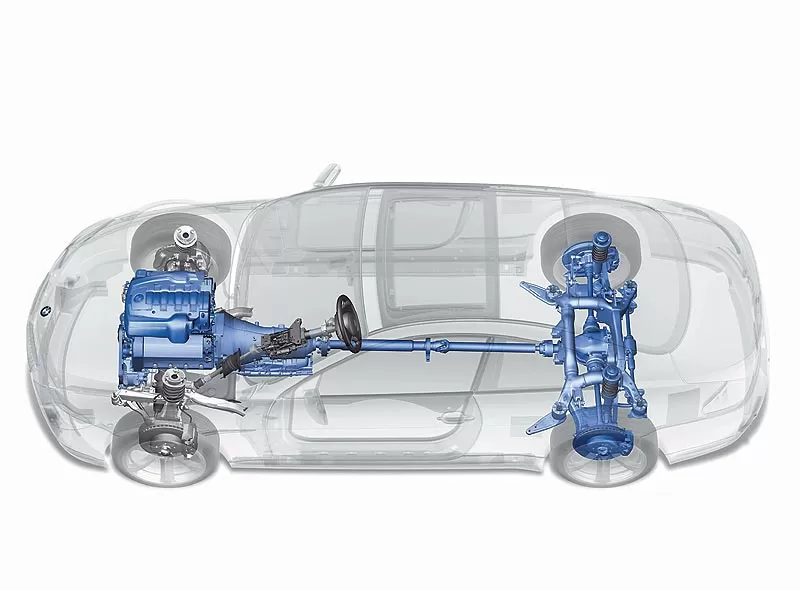

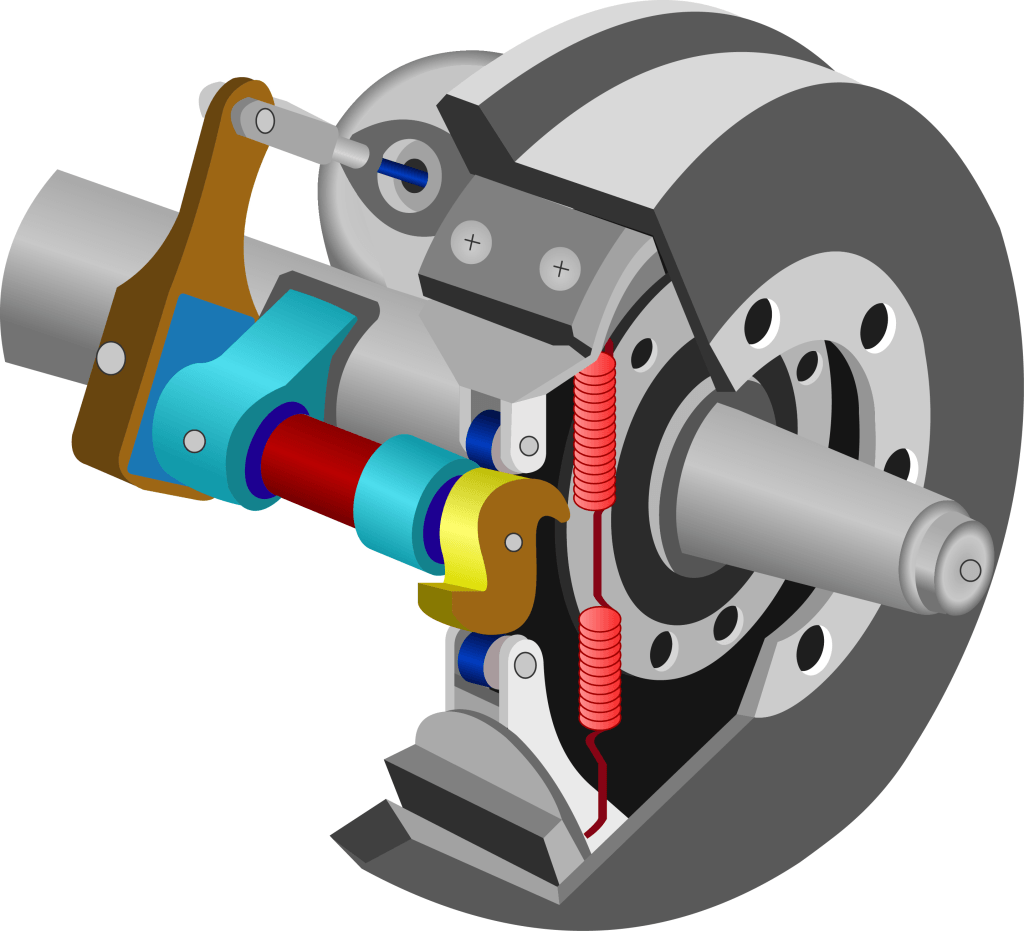

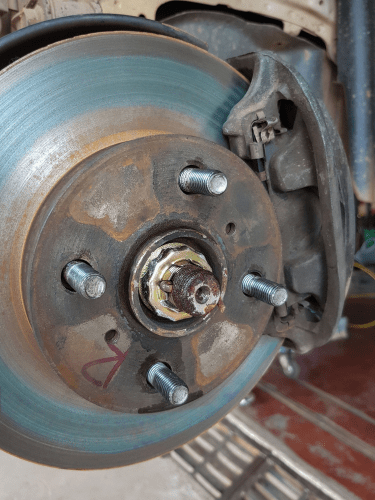

The brake disc consists of a brake bell and a brake ring. . brake bell - This is the central part of the brake disc, which is pulled over the wheel hub and screwed tightly. brake ring - this is the part on which the brake pads are attached.

Brake discs made of gray cast steel , relatively soft and at the same time very durable. The brake disc is subjected to strong frictional forces, which are transmitted with high shear stress at the point of contact between the brake bell and the brake ring. Therefore, it is important that the material has a certain elasticity.

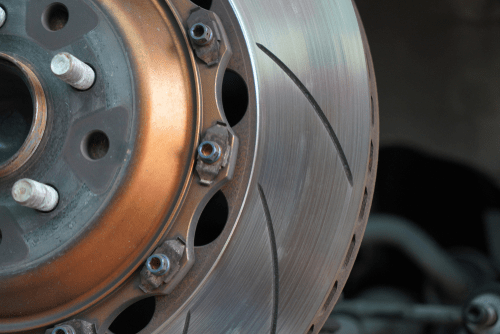

The price to pay for this durability is its high tendency to rust. .

Just three days of a car standing in the rain leads to the fact that a noticeable film of rust appears on the disk , which can be washed away by the very first braking maneuver.

If the vehicle is left idle for a longer period of time, rust will spread quickly.

« Brake cleanliness A badly corroded brake disc doesn't really make sense, as the rust particles act like a cleaning agent on the brake disc and brake linings.

Therefore, the previously mentioned wave effect is a consequence.

To put it in a nutshell:

Flat grinding can be used in case of corrosion and ripples, provided that the minimum thickness of the brake disc is not exceeded. .

Irreparable brake disc damage

It's amazing how even severely corroded brake discs can be made fully functional with this simple and quick method . Including the disassembly and assembly of the wheel and brake caliper, the entire brake disc grinding procedure takes only 10 minutes per wheel . However, treatment has clear limitations, such as:

– minimum thickness

– material damage

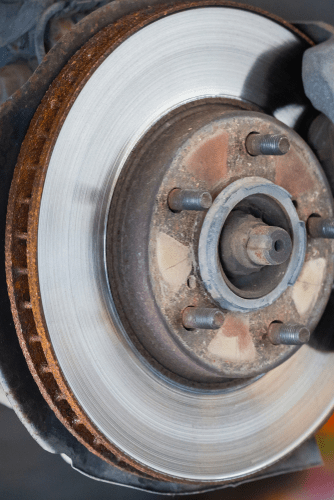

The minimum brake disc thickness is determined by the brake disc manufacturer and is stamped on the brake caliper. . It does not specify a brake failure limit. It just says "up to this size a new set of brake pads can be installed" . All of this is designed to ensure the safest possible outcome of brake system maintenance.

Depending on the damage to the brake disc, this minimum thickness may inadvertently be exceeded when grinding. . In this case, all the work was in vain. Therefore, be sure to carefully inspect the disc before processing.

Inspection of the brake disc automatically includes a check for cracks . They can occur at the edges, at the junction of the ring and socket, as well as in holes for drilling. If there's only the slightest crack , the disc can no longer be used. This means the end for the opposite component as well. Brake discs are basically replaced on each axle.

Beware the blues

As a rule, a brake disc that has turned blue is repairable if the minimum thickness is not exceeded. . However, a blue coating on the disc indicates that something is wrong with the brake system. Excessive heat leads to the fact that the brake disc turns blue .

Normal braking maneuvers should not have this effect. . If, for example, the brake pistons are stuck and brake pads no longer detach from the brake disc , this is exactly what happens: brake pads constantly rub against the disc with slight pressure . The friction causes the brake disc to heat up constantly, eventually turning it blue.

In this case, the entire function of the brake should be checked before lapping.

What else needs to be done

When severe ripples form on the brake discs, the brake pads should be replaced. . Because the the brake caliper was still removed for grinding , this means only one additional measure.

Brake pads are cheap wear parts. . Their replacement is included in the service offered by most grinding service providers. Otherwise, worn brake pads would cause similar brake disc wear and all work would be useless.

Often cars are left standing on the street for a long time. In this case, instant brake disc rust inevitable . As in most cases, just enough to grind the surface of the brake disc . Brake linings should be checked for size and should be sufficient. However, the brake piston may seize if the vehicle is parked for a long time. . A disassembled brake caliper is the perfect opportunity to restore the full performance of the brake piston. To do this, the brake pads are removed and the brake is activated.

Now The brake piston is set to its original position using a brake piston return tool. With a price of 15–50 euros, this tool is quite cheap . However, checking and repairing brake pistons is best left in the garage. If she is not in surface polishing package then you need to add this option. This does not greatly increase the cost of repairs and restores complete safety. .

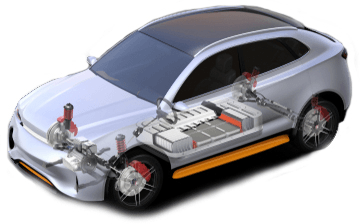

When the wheel is disassembled and the brake caliper is dangling to the side, this is an excellent opportunity to inspect the front axle steering mechanism. . Fixing other damages now makes the car safer and saves additional costs. Pay special attention to the following points:

| - tightening of the axle shaft bushings – state of the ball joint – state suspension pivot - the appearance of noise in wheel bearings – operation and condition of the shock absorber, coil spring and strut bearing – a condition of the cross-section lever and a bar of the stabilizer. |

All of these components are relatively easy to replace in a disassembled vehicle. . The occasion must be used to the best advantage. A freshly polished brake disc is useless if other vehicle components are worn beyond wear limit . The attachment a few more shillings now restores full driving safety. It should be worth it.