When to replace cymerings?

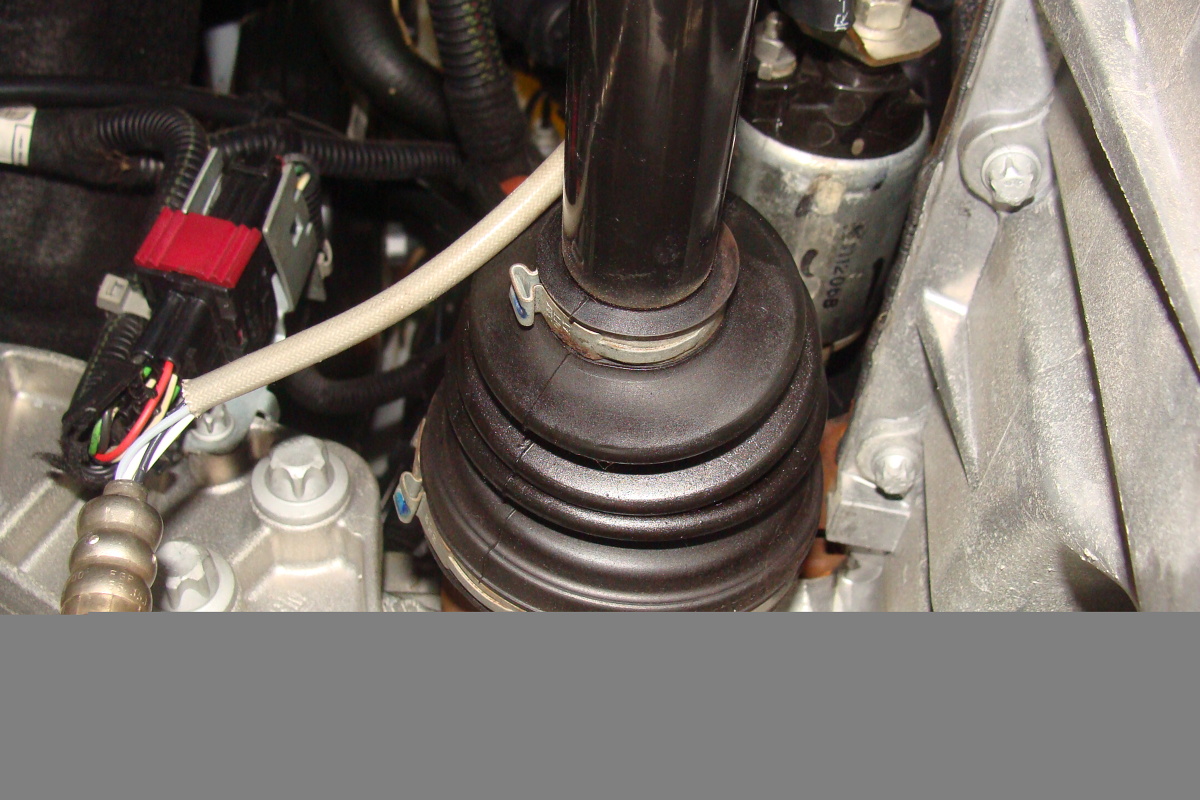

To seal rotating rollers of various types, rubber rings of the Simmerring type, commonly known as zimerings, are most often used.

To seal rotating rollers of various types, rubber rings of the Simmerring type, commonly known as zimerings, are most often used.

These types of seals require that the shaft surface be reasonably smooth (the smoother the better) and that there is virtually no lateral runout of the shaft. Already a roller runout of only 0,02 mm can lead to loss of tightness, as well as minor damage to the surface of the roller. Some of them may be the result of improper, early disassembly of the O-ring.

These types of seals require that the shaft surface be reasonably smooth (the smoother the better) and that there is virtually no lateral runout of the shaft. Already a roller runout of only 0,02 mm can lead to loss of tightness, as well as minor damage to the surface of the roller. Some of them may be the result of improper, early disassembly of the O-ring.

A frequent phenomenon that accompanies the interaction of moving elements of different hardness is an earlier wear of the roller surface than the rubber rim of the ring. This is because the abrasive metal and dust particles that accumulate in the oil or grease adhere to the ring and act as an abrasive that cuts deeper into the steel surface as the roller rotates. As a result, the ring loses its tightness. Therefore, when replacing rings, carefully check the condition of the shaft surface at the point of contact with the sealing lip of the ring. The groove on the roller can be restored by subjecting it to processing, for example, technical chrome plating, followed by grinding. In some situations, you can try to press (if possible) the sealing ring so that its working edge interacts with the surface of the shaft in another place.

O-rings don't just need to be replaced when they start to leak. The technology of various repairs, often for preventive purposes, requires the installation of new rings, even if they have so far worked without any reservations. Simply removing the shaft from the ring can no longer guarantee proper tightness when reassembled.