Motorcycle chain kits: comparison tests, maintenance and theory

Content

Simple, O-ring or low friction chain kits are available today in a variety of qualities, whose performance and durability will also depend on how you care for them. Everything you need to know on the topic is available at the moto station.

The chain and its analogue toothed belt allow two gears to be connected too far apart to be in direct drive. Thus, the chain transfers the tensile force at its extended end from the driven gear of the transmission to the pinion, which is approximately 60 cm apart. Multiplied by the large radius of the ring gear, this force will create more "torque" (or torque) than a gear with a smaller radius. However, this torque value for the crown wheel is the same as for the rear wheel, since they are made in one piece and have the same axis of rotation. Thus, the significant torque on the drive wheel (rear) and the relatively low mass of the motorcycles explain their “canonical” timing, even in 6th place! Of course, for the 5th, 4th or less, the gear torque will always be higher, so the torque at the crown and therefore at the rear wheel will increase in the same proportion. Will you follow through?

Different types of chains

Simple chain is the oldest and certainly the most famous. Due to the more difficult maintenance (and therefore faster wear) and high performance of modern engines, it has long disappeared from most motorcycles. However, for economic reasons, 50 cm3 and about 125 cm3 remained. However, a simple chain retains a great advantage: no friction in the joints, since there is no friction, and therefore no losses! More cumulatively cost effective than an o-ring chain, so it is still widely used in competition...where performance is important and durability is secondary.

Ring chain appeared precisely to solve the problem of lubrication of roller axles. Indeed, during operation, the grease is quickly removed from this strategic location and is difficult to replace, leading to rapid wear on the assembly. To remedy this, the manufacturers had the idea to insert an o-ring called "O'ring" (due to the cross-section in O) between these pins and their side plates. Trapped, protected from water, sand and more, the original grease stays in place for longer, thus taking care of the axles and therefore providing an extended service life!

However, this O-ring chain is still maintenance-free: first of all remember to clean it regularly and then lubricate the outer rollers with SAE 80/90 EP gear grease, always on the teeth. Unless you opt for a chain lubricator such as a Scottoiler, Cameleon Oiler or other that will lubricate it for a long time.

If the chain is too dirty, you can brush it off using diesel, household fuel, or even deodorized gasoline (see, among other things, the excellent morphing tutorial on the ms forum). Warning: Never use gasoline or, moreover, trichlorethylene, as this can damage the axle seals! And take care to protect the rear tire from any protrusions by covering it with a cloth.

With good care, the life of an O-ring chain doubles on average compared to a simple chain, sometimes exceeding 50 km. The other side of the coin is that there is a lot of friction, especially when they are new before running in! To be convinced of this, it is enough to compare the bending forces of the strands offered by AFAM, for example, during motorcycle exhibitions or, even better, for maneuvering a motorcycle before and after installing the chain without O-rings ... Indeed, once in motion, the chain must bend in order to blend harmoniously with the gear and crown. During this rotation, the seals rub between the inner and outer plates, slowing down the movement, thus "eating up" power, or rather, today, increasing fuel consumption!

It is for this reason that low friction chain, which prides itself on combining the best of both worlds: less friction (hence less power loss) and good durability. But how then? The secret lies in the shape of the gasket – from O'Ring to X'Ring or round to cross – and the choice of materials or nitrile for the X'Ring. In short, here is a product that on paper has all the qualities anyway. It remains to be seen, the measurement on the bench...

Chain, grease, oil and wear

Sanson's advice, from the ms forum

Grease is smooth grease: it is not oil.

Oil is liquid: it flows more or less quickly, but it does.

This is the case of “SAE 80/90 EP” gear oil.

In fact, according to the terminology, it is an oil for automobile axles (EP = Extreme Pressure).

Gear oil is often thinner.

Fat is 2 products; soap and oil. Soap's role is to absorb oil like a sponge. Depending on the pressure and capillarity, the soap will spit out oil.

Soap is chemically a product of the reaction of an acid with a fatty substance, namely metal soap, the result of the reaction of a fatty acid (stearic, oleic) with a metal hydroxide (calcium, lithium, sodium, aluminum, magnesium) or a lubricant. We are talking about lithium soaps, for example, lithium salts as solid lubricants. (Yellow colored fluid grease suitable for high speeds (for grease) and low pressure.)

Therefore, the expression: "with lubricant of the SAE 80/90 EP gearbox type" is inappropriate: in this case, one should say "oil", or rather "lubricate".

PS: Oil is not suitable for chain lubrication: it will act as a solvent, thinning the lubricant. As a result, the grease will be removed from where it should be (around the link axis). Even if there are o-rings or X-rings, the seal is far from perfect. The tolerance required for the O-ring is 1/100 mm, which is far from the precision of the chain.

Only a solvent-based grease with very strong capillarity will allow it to penetrate the O-ring despite the O-ring and grip the link shaft. When the solvent evaporates (by diffusion), the grease remains and the solvent carries over the grease.

Neither gear teeth nor rollers should be lubricated. No wear and tear on both (at normal times). Indeed, so-called rollers are located around the axes of the links.

What's more, the exact terminology of our motorcycle chain is "roller chain" (the outer part, often shiny after rain, that rolls over the teeth of the gears). Therefore, the rollers do not wear out if they roll well.

Chain wear has two sources:

- the first is the wear of the axis and the hollow cylindrical part of the link. As the chain rotates, there is friction between these two parts. Normally there should be no metal/metal contact at this level. The grease, by virtue of its consistency and extreme pressure properties, must act as an interface so that the surfaces "slide" over the grease.

Under the influence of high pressure (the tension of the engine on the chain is measured in tons!) Lubricant can flow and water can penetrate, so that contact occurs directly from metal to metal. Then there is a metal gap, in the worst case, a weld. This is a known hard point, for a piston/cylinder this would be a puff.

As soon as a person enters these zones, where the lubrication is imperfect, the geometry of the links changes: the chain lengthens due to increasing games (wear). The chain pitch changes, so the winding is no longer optimally performed on the pinion and crown. On a worn chain, it is clearly visible that the correspondence of the chain to the teeth is approximate, the chain that has passed the first links has come off. The power only passes through a few links, which are subjected to even more stress and the chain is lengthened even further.

- gradually, and this is the second cause of wear, the rollers no longer roll over the teeth, but tear along them, which leads to wear of the teeth of the shape you know: the “rooster comb” on the output gear of the gearbox. and "saw teeth" on the crown.

Let's find a way to always have grease-filled axes, an optimal interface (both cold and hot), and we have chains that never wear out (or barely wear out)!

Note: Timing chains in a sealed case and in an oil bath are noisy, but hardly destroyed.

Continuing our motorcycle chain report ...

[-split: comparative-]

Comparison of motorcycle chains

The Truth About O'ring and X'ring Low Friction Ring Chains

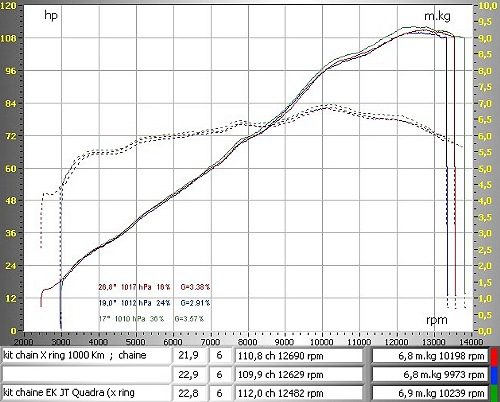

It is difficult to draw a conclusion about the effectiveness of the circuit without having at least one comparative measurement on the bench. To do this, we contrasted Enuma's classic O-ring chain kit (O'Ring) with another low-friction (X'Ring) model from Prokit. The guinea pig motorcycle is a Kawasaki ZX-6R, which was held at the Fuchs BEI 261 booth at Alliance 2 Roues (Montpellier).

For this first test, the bike is equipped with an original chain set, namely a model with classic o-rings such as Enuma EK MVXL 525 with 108 links and 28 km, which is kept in good condition and still in good condition. Bench measurements are smooth:

ZX-6R Measurement with Ring Chain: 109,9 HP at 12 rpm and a torque of 629 μg at 6,8 rpm

Following the standard O'Ring chain, the low friction X'Ring reveals its secrets ...

It remains to disassemble the old chain set and replace it with a Prokit EK + JT assembly with a 525 UVX (red!) Low friction chain for a new measurement on the bench. Nearly identical weather conditions should provide the same measurement accuracy. The disadvantage, like any mechanical component, the chain requires a run-in of about 1 km. This first test is only carried out after 000 km, when the chain still needs to be sufficiently "tight".

Nevertheless, The Ninjette produces 112 horsepower. @ 12 rpm with 482 μg torque @ 6,9 rpm or 10 hp and another 239 mcg! The already remarkable performance can undoubtedly be attributed to the famous X'Ring Quadra low loss seals from the EK patent. Thus, a 30-50% increase in chain friction with conventional O-rings seems to be confirmed. It remains to retest after 1 km.

Fast time travel, the second measurement is taken a few weeks later, after 1 km "around" on the local A000: Kawasaki ZX-9R, identical in all respects (and a well-oiled chain!), Returns to the same measuring stand. Logically, the rollers and plates have taken their place, the X-Ring seals too, we should logically get even more significant gains ... The transition to the bench somewhat contradicts this expectation. The increase in power and torque was halved to 110,8 hp. almost identical torque is observed. You would think that X-Rings broke quickly due to reduced contact points? So the friction surfaces would increase, resulting in losses equivalent to those of O-ring chains? In any case, it is an observation that follows from this comparative test, low friction chains finally showed less significant gains than we expected, but convincing enough in this test anyway to merit our attention.

Did you know?

– we were able to measure this on the Fuchs bench: a properly lubricated chain can reduce transmission losses from 22,8 to 21,9 mN and therefore restore 0,8 horsepower, i.e. almost 1% of power in the case of our test Kawasaki ZX-6R !

- a chain of 520, this means: 5 = chain pitch or distance between two consecutive links; 2 = chain width

We thank Alliance 2 Wheels and Fox for their technical assistance.

All information about Prokit EK low friction chains is here.

Continuing our motorcycle chain report ...

[-split: Service-]

Did you know?

Why is the chain wearing out?

There are several reasons for this:

- atmospheric conditions: rain "washes" the chain, removing grease, but sticking to it, road dirt, including sand, and this "road slush" acts as a powerful abrasive, destroying it very quickly.

– lack of tension control: if the chain is too tight, for example, the wheel bearings and especially the output gear shaft of the gearbox can quickly fail, resulting in high repair costs! Too loose, it will cause jerks and wear even more.

– without lubrication: although the chain has O'Rings or X'Rings, the other elements, the head, the gear and the outer part of the chain must be lubricated (dry friction = very accelerated wear).

– driving style: if you are running at every traffic light and doing other acrobatic stunts, circuit limits will be very important. Such torture will quickly weaken her, and then destroy her ...

For more on maintenance see also the excellent channel tutorial on the ms forum

Service, replacement

Professional advice

It is best to use the end of the chain tensioner stroke and the pointed teeth of the bit to consider replacing the entire chain set. Indeed, the components of the kit (chain, crown, gear) broke off for kilometers. If the output gear of the transmission remains worn out, for example installing a new chain will accelerate its wear! In short, a false good idea of economy ... In short: as soon as the chain tension adjustment reaches the end of its travel, replace everything!

If the chain does not require reassembly, which is the most common case, you can also grind the link or use a diverter to quickly disassemble everything. Reassembly is also quick, but special attention will be paid to riveting the master link and centering the rear wheel.

Before you lubricate the chain, do not forget to clean it: there is no point in covering accumulated and very harmful dirt with grease! A high pressure hot water cleaner is effective, but pressures between 80 and 120 bar can cause water to penetrate even through the O-rings! Therefore, give preference to the classic brush cleaning with the so-called "smokeless" or kerosene oil.

If your motorcycle does not have a center stand, a car jack and an extended side stand can help by allowing the wheel to spin in a vacuum and regularly cleaning and lubricating its chain.