Compressor model 500 3509016

Content

- Aurida pneumatic compressor. MAZ 500-3509015-B1

- Compressor MAZ, KrAZ, K701 with a pulley (CJSC Panevezgio Aurida)

- 14 070 ₽

- Pneumocompressor, article 500-3509015 B1 (210l/min)

- Compressor KrAZ, MAZ (YaMZ-7511) with a pulley (CJSC Panevezgio Aurida)

- 16 217 ₽

- 14 pc

- The device and principle of operation of the compressor KAMAZ (5320-3509015-10) PK 214-30

- Construction and scheme of actions

- Rice. 1 - Compressor KAMAZ (5320-3509015-10) two-cylinder

- Borisov Plant of Aggregates JSC

- Delivery - two-cylinder KAMAZ compressor - in Russia

- 4122-210 — KAMAZ compressor (delivered to the KAMAZ conveyor)

- Maintenance

- Fault detection of compressor parts

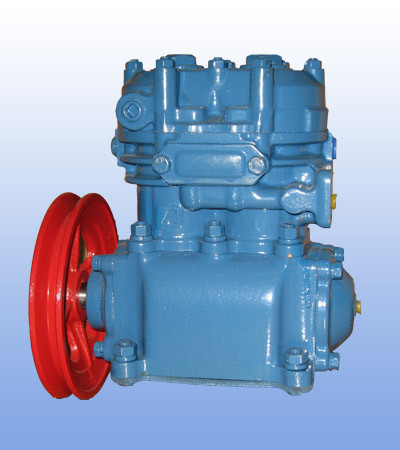

Pneumatic compressor 500-3509015 Piston type B1, two-cylinder compressor (base model 130-3509).

Aurida pneumatic compressor. MAZ 500-3509015-B1

Compressor drive via pulley (size Ø172 mm).

The cylinder head is cooled by liquid from the engine cooling system, the cylinder block is cooled by air.

The compressor lubrication system is mixed. Oil is supplied from the engine lubrication system.

Compressor specifications:

• Nominal cylinder diameter, mm — 60

•Piston stroke, mm — 38

• Nominal working volume, cm3 — 214

• Shaft speed, min-1:

Secret - 2000

Maximum — 2500

•Productivity, l/min — 201 (at a crankshaft speed of 2000 rpm and back pressure of 700 kPa)

•Power consumption, kW - 2,17

• Weight, kg - 14,8

Application of pneumatic compressor:

•Avtomobile

K-701 and other modifications

Ural - 4320 and other modifications

Kraz - 255, 256, 6510 and other modifications

Belaz

MAZ-5336, 64229 and other modifications

• Base engine

YaMZ-236, 238 and other modifications

Compressor interchangeability:

•16.3509012 (depending on engine and car model)

•161.3509012 (depending on engine and car model)

•161.3509012-20 (depending on engine and car model)

•130-3509009-11 (depending on engine and car model)

•540-3509015 (depending on engine and car model)

Similar thing:

Similar compressors are developed on the basis of compressor 130-3509 with the same characteristics and performance:

•16.3509012 — with pulley Ф 172 mm

•161.3509012 — with pulley Ф 172 mm

•130-3509009-11 — without pulley with unloader

•130К-3509012 — with pulley Ф 262 mm with pressure regulator

•157К-3509012 — with pulley Ф 242 mm with pressure regulator

•157KD-3509012 — with pulley Ф 220 mm with pressure regulator

•540-3509015 — without pulley

Scheme of the compressor MAZ 500-3509015 B1

Compressor MAZ, KrAZ, K701 with a pulley (CJSC Panevezgio Aurida)

Compressor MAZ, KrAZ, K701 with a pulley (CJSC Panevezgio Aurida)

14 070 ₽

Code: 000019428

57 pc

15 074

Code: 000047446

56 pc

13 612

Code: 000014971

23 pc

6 590

Code: 001017043

Manufacturer: VAZ

21 pc

11 380

Code: 000195942

Producer: PANEVEJO AURIDA

14 pc

16 217

Code: 000018370

Producer: PANEVEJO AURIDA

12 pc

14 960

Code: 001557347

9 090

Code: 001557349

7 720

Code: 001557344

8 990

Code: 001017046

Manufacturer: VAZ

11 636

Code: 000016444

Producer: PANEVEJO AURIDA

13 310

Code: 001561673

11 290

Code: 001561682

11 290

Code: 001363612

Order

Code: 001320590

Order

Code: 001410481

Manufacturer: Sorl

Order

Code: 001557341

Order

Tell us about your problem

Thank you! Your feedback is very important to us and helps us improve search results for all of our customers.

As soon as the price of a commodity falls,

you will know right away

Dynamics of changes in the average price for six months

Pneumatic compressor 500-3509015 Piston type B1, two cylinders (base model 130-3509). Compressor drive via pulley (size 172 mm). The cylinder head is cooled by liquid from the engine cooling system, the cylinder block is cooled by air. The compressor lubrication system is mixed. Oil is supplied from the engine lubrication system.

- K-701 and other modifications;

- URAL-4320 and other modifications;

- Kraz - 255, 256, 6510 and other modifications;

- BelAZ;

- MAZ-5336, 64229 and other modifications;

2. Base engine: YaMZ-236.

Nominal cylinder diameter, mm — 60

Nominal working volume, cm 3 - 214

Shaft speed, min-1:

Productivity, l / min - 201 (at a crankshaft speed of 2000 rpm and a back pressure of 700 kPa)

Power consumption, kW - 2,17 Weight, kg - 14,8

Source

Pneumocompressor, article 500-3509015 B1 (210l/min)

Manufacturer's Warranty

Delivery of spare parts in Moscow and Russia

Delivery of spare parts in Moscow and Russia

Our company has its own parking lot. Finished products will be delivered by transport to the place of residence of the end consumer or to a transport company.

Delivery to the terminal of the transport company or to the buyer within the Moscow Ring Road is free of charge.

Delivery of spare parts to the buyer in the Moscow region is free of charge when ordering from 200 rubles, within a radius of 000 km from the Moscow Ring Road - free of charge when ordering from 500 rubles.

Cash payment (Russian rubles) is possible. The transaction limit is 100 rubles under the purchase and sale (supply) agreement. At the same time, a complete set of documents related to the Goods is issued, including a cash receipt.

Cash foreign currency is not accepted for payment.

| Analogues |

| Pneumocompressor (300l/min) (AM.3509015-500-B1, Izhevsk) |

| 500-3509015 B1-RKS |

| Price: 9940 rubles. |

| Pneumatic compressor (210 l/min) (Panevegio Aurida. Lithuania) |

| 161.3509012 |

| Price: 15729 rubles. |

Autoresurs offers to buy MAZ spare parts in small and large wholesale in Rostov-on-Don and other cities of Russia.

You are in the "MAZ brake system" section. On this page of our online store you can order Pneumocompressor (210l/min) (Panevegio Aurida. Lithuania) article 500-3509015 B1. To do this, you need to specify the amount you need and send a request. Your order will be completed as soon as possible.

If you have the slightest doubt that the part number 500-3509015 B1 is exactly what you need, be sure to contact our company managers. They will help you solve any of your doubts.

Source

Compressor KrAZ, MAZ (YaMZ-7511) with a pulley (CJSC Panevezgio Aurida)

Compressor KrAZ, MAZ (YaMZ-7511) with a pulley (CJSC Panevezhgio Aurida)

16 217 ₽

14 pc

Code: 000019428

57 pc

15 074

Code: 000047446

56 pc

13 612

Code: 000014971

23 pc

6 590

Code: 001017043

Manufacturer: VAZ

21 pc

11 380

Code: 000018370

Producer: PANEVEJO AURIDA

12 pc

14 960

Code: 001557347

9 090

Code: 001557349

7 720

Code: 000195944

Producer: PANEVEJO AURIDA

14 070

Code: 001557344

8 990

Code: 001017046

Manufacturer: VAZ

11 636

Code: 000016444

Producer: PANEVEJO AURIDA

13 310

Code: 001561673

11 290

Code: 001561682

11 290

Code: 001363612

Order

Code: 001320590

Order

Code: 001410481

Manufacturer: Sorl

Order

Code: 001557341

Order

Tell us about your problem

Thank you! Your feedback is very important to us and helps us improve search results for all of our customers.

As soon as the price of a commodity falls,

you will know right away

Dynamics of changes in the average price for six months

Pneumatic compressor 161-3509012-20, piston, two-cylinder. Compressor drive via pulley (size 172 mm). The cylinder head is cooled by liquid from the engine cooling system, the cylinder block is cooled by air. The compressor lubrication system is mixed. Oil is supplied from the engine lubrication system.

- MAZ-5336, 64229 and other modifications;

- Kraz - 255, 256, 6510 and other modifications;

- Ural-4320 and other modifications;

- BelAZ;

2. Base engine: YaMZ 236, 238 and other modifications.

Source

The device and principle of operation of the compressor KAMAZ (5320-3509015-10) PK 214-30

Group of companies "SpetsMash" offers to get acquainted with the news material Two-cylinder compressor KAMAZ and choose the appropriate product in our catalog 8 (495) 225-58-418, (800) 555-92-41

Construction and scheme of actions

The design itself is as follows: a connecting rod, a piston, a cylindrical element with a nozzle, rings, plain bearings, a crankcase, a crankshaft, a drive gear.

Two-cylinder and single-cylinder KAMAZ compressors are based on the piston principle. The general scheme of actions looks the same. The equipment has a liquid cooling system. The piston is made of ductile iron and is equipped with two compression rings and one oil scraper. With the help of studs, the cylinder block is attached to it together with the cylinder head, equipped with poppet discharge valves. The steel crankshaft sits directly in the crankcase. For this, two ball bearings are used. The cylinder block contains pistons connected to the connecting rods by means of floating rings. In this case, the lower head of the connecting rod is removable. For the penetration of air into the cylinders, special inlet covers are made, located on the side in the compression chambers.

See also: How to disassemble the refrigerator compressor

The element itself is installed at the end of the power unit. Its main task is to generate and shape the air supply for the pneumatic systems of the machine. The compressor for a KAMAZ vehicle, single-cylinder or two-cylinder, supplies compressed air masses to the working chamber. As a result, the completeness of combustion of the fuel mixture and engine power increase. The operation of the component begins with the engine running: the process of pumping and supplying compressed air to the pneumatic system begins.

When the pressure value of the pneumatic system reaches the mark of 0,8-2 MPa, the pressure regulator is activated and the air supply is stopped. The exhaust valve closes and the intake valve opens. Air masses from the space under the follower piston pass into the cavity located above the delivery piston. When the parameter drops to 50 kPa, the output closes. From this point on, the element again begins to pump air masses into the pneumatic system. Receivers help to store the supply of compressed air pumped by the compressor element.

Rice. 1 - Compressor KAMAZ (5320-3509015-10) two-cylinder

1 - compressor crankcase; 2 - bearing; 3 - front cover of the compressor; 4 - stuffing box; 5 - pulley; 6 - wedges; 7 - compressor cylinder block; 8 - piston with connecting rod; 9 - compressor head; 10 - retaining ring; 11 - bearing; 12 - thrust nut; 13 - rear cover of the compressor crankcase; 14 - sealant; 15 - spring seal; 16 - crankshaft; 17 - intake valve spring; 18 - inlet valve; 19 - intake valve guide; 20 - rocker spring; 21 - inlet valve stem; 22 - rocker; 23 - plunger; 24 - sealing ring; 25 - transport fork.

Borisov Plant of Aggregates JSC

The Commonwealth of Companies "Auto-Alliance" offers original products manufactured by OJSC "Borisov Plant of Aggregates" (BZA), one of the leading manufacturers of turbochargers, compressors, pumps and filters for automotive vehicles. The use of new technologies and modern equipment in the development and production of products is the general direction in the development of the company. The turbochargers use a more advanced bearing assembly with a single hub installed that works like a centrifuge, which allows the use of lower quality oil and increases the life of the bearing assembly. Pneumatic compressors use a reed valve instead of a traditional spring valve, which allows a significant increase in compressor performance without making changes to the design. 6D design is used to develop new products and upgrade existing ones. Tools are made according to three-dimensional models, which allows us to produce products with the highest quality characteristics. For the production of castings for compressor wheels and turbine wheels, the plant has implemented unique technologies for casting thin-walled castings according to elastic patterns into disposable plaster molds by vacuum suction and vacuum investment casting. For the manufacture and testing of compressors, the plant has developed and implemented modern precision technologies used in serial and large-scale production. Processing of parts is carried out according to 7-100 degrees of accuracy. The plant introduced the balancing of the turbocharger rotor assembly with the bearing housing using the equipment of the world leader in the production of balancing equipment, the German company SCHENCK, at operating speeds of more than XNUMX thousand revolutions per minute. RUE "Borisov Aggregate Plant" actively cooperates with research organizations, applying the latest achievements of science and joint developments in production. Leading scientific organizations of the republic participate in the development of a competitive turbocharger of a high technical level together with the company's specialists, using the latest achievements of science and joint developments in production. Leading scientific organizations of the republic participate in the development of a competitive turbocharger of a high technical level together with the company's specialists, using the latest achievements of science and joint developments in production. The leading scientific organizations of the republic are involved in the development of a competitive turbocharger of a high technical level together with the company's specialists.

• Oil filters and more

Go to brand page

53205-3509015-02 ПК 306-01, 53205-3509015

KNORR-Bremse was founded in 1905 by Georg Knorr. Initially, the company focused on the production of auto parts and components for industrial equipment. Today the company has become the world's leading supplier of various braking systems for freight and rail vehicles. The company is developing dynamically: over the hundred years of its existence, it has gone beyond the domestic market and has become an international concern. The structure of the company includes factories and subsidiaries located in 25 countries of the world, as well as a developed distribution network covering 60 countries of the world. Knorr-Bremse offers a complete range of pneumatic and electronic braking systems for commercial vehicle manufacturing and the aftermarket. The product range covers the entire brake system, from air preparation to brake mechanisms. Knorr-Bremse offers a range of control systems including air suspension and stability control. The main goal of Knorr-Bremse is customer satisfaction, which is the basis of our overall success. Knorr-Bremse strives to ensure that each of its employees in the performance of their duties is focused on the consumer. To date, KNORR-BREMSE offers the widest range of brake systems for trucks, including pneumatic, pneumohydraulic, electronic systems; suspension systems for all commercial vehicles, wheel brakes and control systems. Knorr-Bremse is the world's leading supplier of braking and control systems for commercial vehicles. Knorr-Bremse is a supplier to all major car manufacturers worldwide and pays special attention to the quality, reliability and safety of its products. All products have ISO 9001 and ISO TS16949 quality certificates introduced in 2001. The company is also an innovative developer of advanced pneumatic and electronic systems. Disc brakes manufactured by Knorr-Bremse are light up to 50 kg but deliver 900 kW of braking power. As a result, Knorr-Bremse braking systems are virtually unrivaled in reliability and efficiency, while Knorr-Bremse electronic systems provide the highest level of vehicle control: the system is activated in milliseconds. The reliability of Knorr-Bremse systems is due to the strict adherence to the production technology and the know-how used. Knorr-Bremse's new generation compressors are the optimal solution for commercial vehicles. These compressors are characterized by low oil emissions, high efficiency and low air inlet temperature. The optimal energy saving system reduces energy consumption. The company manufactures a full range of brake chambers compatible with a wide range of vehicles. Knorr-Bremse is also a leading manufacturer of air disc brakes for trucks, buses and trailers.

Go to brand page

Commonwealth "Auto-Alliance" brings to your attention the compressor of JSC "Panevegio AURIDA", Lithuania. The main activity of the plant is the production of one- and two-cylinder autocompressors designed to supply compressed air to the brake systems of trucks, buses, tractors. CJSC "Panevegio Aurida" was founded in 1995 on the basis of the former Panevėžys Auto Compressor Plant, which has experience and traditions in the production of automotive compressors since 1959. Aurid has long and fruitful cooperation with KAMAZ, LAZ, PAZ, KRAZ, MAZ. ", "ZIL", "Petersburg Tractor Plant" and other plants-consumers of compressors. The main products of the company are single-cylinder and two-cylinder pneumatic compressors for cars, the working volume of which is from 73 to 306 cm3, cooled by air or liquid from the car cooling system. The compressor license of the German company KNORR-BREMSE acquired and put into production for KAMAZ engines raised the technical level of the plant. Since 2002, the plant has implemented a certified quality management system in accordance with the international standard ISO 9001:2000. Since 2004, an environmental management system has been introduced in accordance with ISO 14001:1996. Compressors manufactured by CJSC Paneveggio Aurida are certified in the GOST R certification system of the State Standard of Russia and Ukraine. In 2005, a program is planned to master the production of aftermarket compressors for VOLVO, MAN, Deutz engines, and automobile pneumatic compressors are used for almost all types of trucks, buses (KAMAZ, LAZ, PAZ, KrAZ, MAZ, ZIL). They are designed to supply compressed air as an energy carrier”

See also: Compressor for autonomous refrigeration 8w 600 lh

Go to brand page

Delivery - two-cylinder KAMAZ compressor - in Russia

KAMAZ two-cylinder compressor

transport companies Kama-Auto, DPD, Baikal-Service, Autotrading, Auto-Logistics, Kama-Trucks, Energy, Ratek, Kama-Express, SDEK, Volga-Trans to any city in the Russian Federation: Kaluga Noyabrsk Novy Urengoy Labinsk Konakovo. Irkutsk Klin. Novomoskovsk Kolchugino Nizhneudinsk Pushkino Zarinsk Petropavlovsk Klin. Solikamsk Ufa Krasnograd Petropavlovsk-Kamchatsky Mamadysh Vladivostok Kansk Yoshkar-Ola Brest Lisichansk Polevskoy. Novosibirsk Krasnoarmeysk Kopeysk Nizhnyaya Salda. Langepas Kizlyar Sergiev Posad Bronnitsy Primorsk Kirishi Novoshakhtinsk. Gubkinsky Vysotsk Kyzyl Ussuriysk Berdsk Ozersk Zaraysk Novoshakhtinsk. Ust-Kut Magadan Tyachev. Moscow Uman Belebey and others

Recommended for purchase: Fuel tank 650 l assembly (650x650x1650) 1101010-10-5320, price: 11472 rubles, Thermostat housing tube (YaMZ Avtodiesel) 1306053-01-658 cost: 110,5 rubles, Two-cable trailer crane (Autocomponent ) 3531010.16, price 2005,68 rubles, ZF Gearbox bearing ZF (0735320816) 0750115971, price 732 rubles. 250712, Price: 35,1 r, Cardan steering cross 3422039-5320, Price: 257,04 rubles,

4122-210 — KAMAZ compressor (delivered to the KAMAZ conveyor)

The single-cylinder compressor 4122-210 is temporarily unavailable as a spare part and is supplied only for the KAMAZ transporter, the analogue 4122-211 is supplied below, there is a link to an analogue with completely repeating technical characteristics and application.

Compressor 4122-210 with a universal head was approved for serial delivery by KAMAZ PJSC in 2014.

The performance of the compressor 4122-210 at a nominal speed of 430 l / min, which is 60 liters plus compressor 18.3509015, allows you to supply the maximum amount of compressed air to the vehicle's brake system when operating in urban mode.

The crankshaft of the compressor is equipped with two counterweights: this ensures a balanced operation of the piston group to reduce noise and vibration, and increases the life of the crankshaft bearings.

The service life of the compressor 4122-210 is 8 thousand hours, which approximately corresponds to 650 thousand km of a car run

Compressor warranty 24 months

Technical data of the compressor 4122-210 (4122-211): Number of cylinders 1, Bore 92 mm, Stroke 50 mm, Displacement 332 cm3, Nominal pressure 8 bar, Nominal speed 2000, Maximum speed 3000. Minimum lubricant pressure 0 . 5 bars

Compressor weight 4122-210 (4122-211) 11 kg

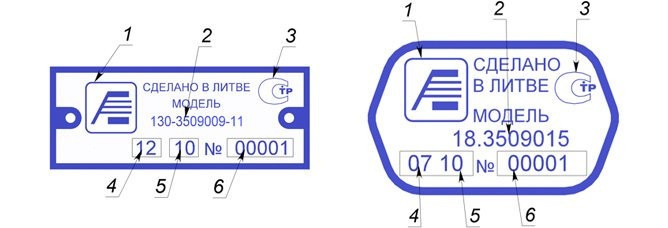

Panevegio-Aurida guarantee conditions are the obligatory presentation of a passport and the preservation of the label on the product. In order to avoid loss of passports, we keep them with us, passports are issued from these persons with a written guarantee from the buyer that in case of any claims, you, the buyer, undertake to keep this passport. Determining the originality of the Lithuanian compressor. Intellectual and industrial property (design) is protected by patented trademarks: (additional photo.1)

Autocompressors have passports, certificates of quality and conformity, body parts are marked with moldings with a registered trademark: (additional photo 2)

An identification plate (company) is attached to each autocompressor: (Additional photo.3)

1. Trademark of the manufacturer. 2. Model of an autocompressor. 3. Mark of compliance with technical regulations regarding the safety of vehicles that carry out mandatory certification in the Russian Federation. 4. Month of manufacture (two digits). 5. Year of manufacture (two digits). 6. Ordinal number. The numbers in paragraphs 4, 5, 6 are stamped with a needle.

Our company guarantees the originality of products and the best prices on the market.

Maintenance

The correct operation of the KAMAZ compressor, whether it is a two-cylinder or based on a single cylinder, is of great importance for traffic safety.

Proper operation of the element virtually eliminates the need for compressor repair. It is enough to monitor lubricants and coolant consumption. At the same time, it is important to strictly follow the technical recommendations. The use of contaminated oil is strictly prohibited. The liquid used must correspond to that specified in the engine passport. Daily diagnostics are not required - it is enough to check the compressor every 7-10 thousand kilometers.

During operation, the cylinder-piston group may wear out and the tightness of the valves may be violated. This type of malfunction requires compressor repair.

Fault detection of compressor parts

If defects are found, the parts with cracks, chips, scratches and potholes on the working surfaces, other mechanical damage are subject to rejection.

Source