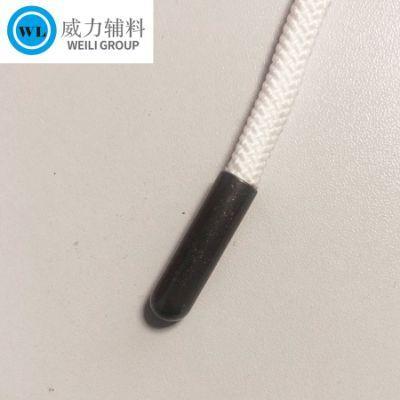

tip end

If there is a noticeable play in the steering wheel, and during movement vibrations are felt on it and individual knocks are heard, then the swivel joints in the steering system are most likely worn out.

If there is a noticeable play in the steering wheel, and during movement vibrations are felt on it and individual knocks are heard, then the swivel joints in the steering system are most likely worn out.

This can be confirmed with a simple diagnostic test. It is enough to raise the car with a jack so that the wheel is steerable  lifted off the ground and tried to vigorously move it in two planes: horizontal and vertical. A noticeable play in both planes can most likely be attributed to a worn hub bearing. On the other hand, a faulty connection in the steering system is usually the cause of the play that appears only in the horizontal plane of the steered wheels. Very often this is a backlash at the end of the tie rod, or rather on its ball joint.

lifted off the ground and tried to vigorously move it in two planes: horizontal and vertical. A noticeable play in both planes can most likely be attributed to a worn hub bearing. On the other hand, a faulty connection in the steering system is usually the cause of the play that appears only in the horizontal plane of the steered wheels. Very often this is a backlash at the end of the tie rod, or rather on its ball joint.

In a typical solution used in both passenger cars and vans, the element carrying the pin ball in such a joint is a one-piece latch seat made of polyacetal, a plastic with high mechanical strength. On the outside of the connection, there is usually a metal plug, which is a reliable protection against dirt and water. The same role is played by a cover made of polyurethane or rubber, clamped both on the hinge body and on the pin. The part of the cover that interacts with the surface of the pin is provided with a sealing lip adjacent to the surface of the switch lever.

Ball joint play can be the result of normal wear or accelerated wear caused by excessive mechanical overload or contamination that has entered between the interacting bearing elements.