Car tire design - everything you need to know about the function of each tire component

Content

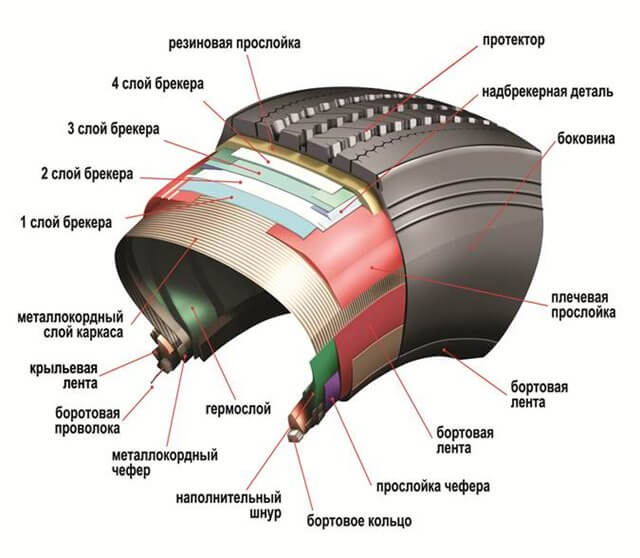

Tires are the only parts of a car that are in direct contact with the ground we drive on. They must be strong enough to safely negotiate bumps and potholes or large and small stones. They must withstand a vehicle weighing several tons and move at speeds up to 200 km/h. Although not everyone knows about it, they have a very complex structure. Are you interested in manufacturing car tires? Read our article to learn more about it!

Tire design – tire tread is key

The tubeless tires we use today date back to 1947. Then they were introduced and are constantly being improved until today. The most important element is the tread, which makes up up to 80 percent of the tire's surface. It is he who is responsible for the stability and grip of the steering wheel while driving. Tracks are of three types:

- symmetric;

- asymmetric;

- directed.

All modern tires are a mixture of natural and synthetic rubber, as well as carbon black. In winter, silica and, for example, resin are added. If you are interested in proportions, we have bad news for you - all manufacturers keep this information secret, they do not want such specific data to fall into the hands of competitors. Because the car tire market is huge and the race is for hundreds of millions of euros in profits. However, for drivers, this is good news - the more you spend on improving tires, the safer and more confident driving becomes, regardless of the conditions.

Tire side

Another important element of the tire design is its sidewall. Manufactured from pre-formed carcass plies as well as rubber (much more flexible than tread). The purpose of this element is to protect the frame from damage and shock, as well as to increase driving comfort. This also affects the transfer of the load.

At the same time, important information for drivers is placed on the sidewall of the tire:

- the size;

- load index;

- speed index;

- date of manufacture of the tire;

- tire manufacturer and model name.

footer

Its professional name is footer, although many call it a collar. Regardless of the name, it performs an important function for every car wheel. It is responsible for stabilizing the connection between tire and rim, which is crucial when it comes to road safety. The foot has a steel core and is also equipped with a rubber cord. This directly affects the protection of the tires due to the increased pressure from the weight of the vehicle.

drum ball

When it comes to tire construction, bead wire must not be forgotten. Its job is to keep the tires on the rim of the rim. Of course, it is made of steel wires, which are connected in coils and embedded in the tire bead. Usually two bead wires are used, which are wrapped with a layer of nylon backing. This affects the transmission of very high loads through car tires without the risk of bursting them.

What is a carcass and what is a tire carcass?

The carcass is nothing more than a layer that surrounds the tire. It is located at the top. Depending on the manufacturer and size of the tire, it consists of several or more than a dozen layers of thin high-strength wire. They are arranged diagonally and glued one after the other. This is necessary to create a dense network of triangles. The task of the carcass is to provide the tire with resistance to high speeds and centrifugal forces acting on it, which can be dangerous when driving. Reduces tire heating effect. When it comes to maximum tread wear, it is this layer that shows up first. It is one of the most important elements of tire design.

The carcass of a tire is the carcass. It is divided into radial models, in which the base is located radially, and diagonal, in which the base is located crosswise. This is an element constructed from a plurality of cord layers, the task of which is to connect the shoulder part of the tire with its frontal zone. The base is usually made of textile fabric and, depending on the manufacturer and size, can be one-, two- or three-layered. The most important task of this element is to maintain the correct shape of the tire. It depends on the quality of recovery whether the tire will be resistant to distortions (may appear during acceleration or braking) and high temperatures. This layer is of key importance in terms of tire durability and quality, and in the case of tire construction, is a priority for tire manufacturers.

The sealing layer is an important structural element

The sealing layer, also known as the bead, is located on the inside of the tire and is the main part of the tire. As you might guess, its task is to protect the tire from water or air getting inside. This layer is resistant to oxidants as well as acids and bases. It is she who is an alternative to the cameras that were previously used in car tires. When you look at the construction of a tire, you will quickly realize that the bead keeps the tire from losing pressure and also provides a protective layer.

Safety while driving

Driving on different surfaces, good tires will keep you safe. Pay attention to the tread, tire surface and rubber layer. It also affects performance, driving comfort and fuel consumption. We should not forget about the level of noise generated by all tires. However, the smaller it is, the more comfortable it is during long hours of driving. Before continuing your ride, check the condition of the tires—tire tension, steel cord condition, and any nasty looking wear. This applies to all-season, summer and winter tires. All of them, although built differently, have similar properties, and the design of the tire does not differ significantly from each other.

A car tire is a very complex structure consisting of several layers. All of them have their own function - and viscose, and polyester, and the lamella are responsible for a specific thing, which means they affect driving comfort. And safety, which in the case of car tires is crucial. The design solutions are advanced, but the manufacturers probably did not say the last word. When it comes to tire construction, we are sure to be surprised more than once. When buying new tires, pay attention not only to the size of the tires, but also to the technologies used.