The design of a multi-plate friction clutch and its and the principle of operation

Content

A multi-plate friction clutch is a type of torque transmission mechanism that consists of a pack of friction and steel discs. The moment is transmitted due to the friction force that occurs when the discs are compressed. Multi-plate clutches are widely used in various vehicle transmission units. Consider the device, the principle of operation, as well as the advantages and disadvantages of these mechanisms.

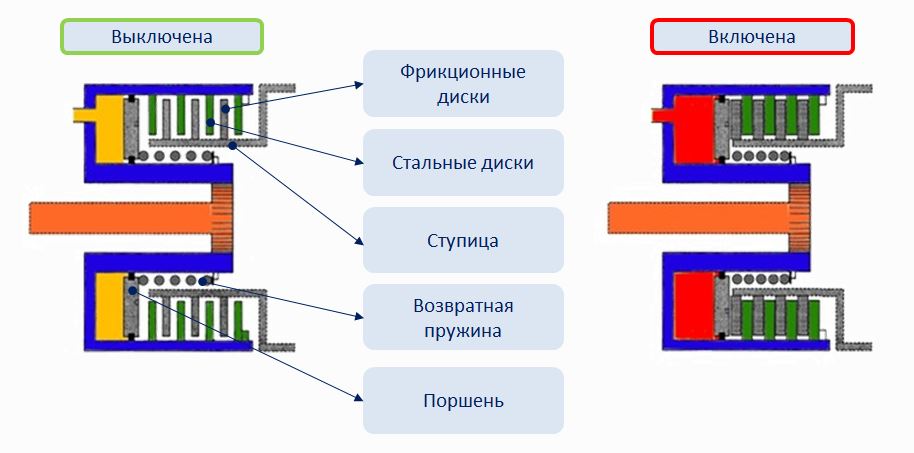

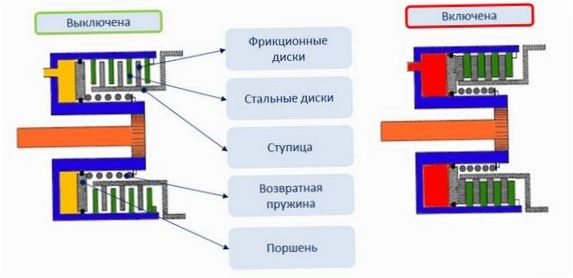

The principle of operation of the coupling

The main task of a multi-plate clutch is to smoothly connect and disconnect the input (drive) and output (driven) shafts at the right time due to the friction force between the disks. In this case, the torque is transferred from one shaft to another. The discs are compressed by fluid pressure.

Please note that the value of the transmitted torque is greater, the stronger the contact surfaces of the discs. During operation, the clutch may slip, and the driven shaft accelerates smoothly without jerking or jerking.

The main difference of the multi-disk mechanism from others is that with an increase in the number of disks, the number of contact surfaces increases, which makes it possible to transmit more torque.

The basis for the normal operation of the friction clutch is the presence of an adjustable gap between the discs. This interval must correspond to the value set by the manufacturer. If the gap between the clutch discs is less than the specified value, the clutches are constantly in a “compressed” state and wear out faster accordingly. If the distance is greater, slippage of the clutch is observed during operation. And in this case, rapid wear cannot be avoided. Precise adjustment of clearances between couplings when repairing a coupling is the key to its correct operation.

Construction and main components

The multi-plate friction clutch is structurally a package of steel and alternating friction discs. Their number directly depends on what torque must be transmitted between the shafts.

So, there are two types of washers in the clutch - steel and friction. What is the difference between them The fact is that the second type of pulley has a special coating called "friction". It is made of high friction materials: ceramics, carbon composites, Kevlar thread, etc.

The most common friction discs are steel discs with a friction layer. However, they are not always steel-based; sometimes these coupling parts are made of durable plastic. The discs are attached to the drive shaft hub.

Ordinary frictionless steel discs are mounted in a drum connected to a driven shaft.

The clutch also contains a piston and a return spring. Under the action of fluid pressure, the piston presses on the disc pack, creating a friction force between them and transmitting torque. After the pressure is released, the spring returns the piston and the clutch is released.

There are two types of multi-plate clutches: dry and wet. The second type of device is partially filled with oil. Lubrication is important for:

- more efficient heat dissipation;

- Lubrication of clutch parts.

Wet multi-plate clutch has one drawback - a low coefficient of friction. Manufacturers compensate for this disadvantage by increasing the pressure on the discs and using the latest friction materials.

Advantages and disadvantages

Advantages of a multi-plate friction clutch:

- compactness;

- When using a multi-plate clutch, the dimensions of the unit are significantly reduced;

- transmission of significant torque with small dimensions of the mechanism (due to an increase in the number of disks);

- smoothness of work;

- the possibility of connecting the drive shaft and the driven shaft coaxially.

However, this mechanism is not without drawbacks. For example, steel and friction discs may burn during operation. In wet multi-plate clutches, the coefficient of friction also changes as the viscosity of the lubricant changes.

Coupling application

Multi-plate clutches are widely used in automobiles. This device is used in the following systems:

- clutch (in CVTs without a torque converter);

- Automatic transmission (automatic transmission): The automatic transmission clutch is used to transmit torque to the planetary gear set.

- Robot gearbox: The dual clutch disc pack in the robot gearbox is used for shifting at high speeds.

- All-wheel drive systems: the friction device is built into the transfer case (a clutch is required here to automatically lock the center differential);

- Differential: mechanical device performs the function of full or partial blocking.