CVT gearbox - what is it?

Content

What is a CVT box, and how does it differ from a traditional transmission? Such a question may be of interest to both existing car owners with this type of torque transmission and future ones. this type of gearbox implies the absence of fixed gear ratios. This gives a smooth ride, and also allows you to use the internal combustion engine in optimal modes. Another name for such a box is a variator. then we will consider the pros and cons of the CVT gearbox, the nuances of its use, as well as the reviews of motorists who already own cars with a continuously variable transmission.

Definition

The abbreviation CVT (Continuously Variable Transmission - English) translates as "constantly variable transmission." That is, its design implies the possibility smooth change transmission ratio between driving and driven pulleys. In fact, this means that the CVT box has many gear ratios in a certain range (range limits set the minimum and maximum pulley diameters). The operation of the CVT is in many ways similar to using an automatic transmission. You can read about their differences separately.

To date, there are the following types of variators:

CVT operation

- frontal;

- conical;

- ball;

- multidisk;

- end;

- wave;

- disc balls;

- V-belt.

The most common type of CVT box is the friction V-belt variator. This is due to the relative simplicity and reliability of its design, as well as the convenience and possibility of using it in a machine transmission. Today, the vast majority of car manufacturers that produce cars with a CVT box use V-belt variators (with the exception of some Nissan models with a toroidal-type CVT box). Next, consider the design and principle of operation of the V-belt variator.

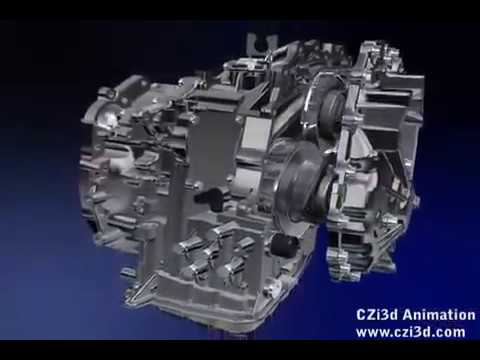

Operation of the CVT box

The V-belt variator consists of two basic parts:

- Trapezoidal toothed belt. Some automakers use a metal chain or belt made of metal plates instead.

- Two pulleys formed by cones pointing towards each other with tips.

As the coaxial cones are closer to each other, the diameter of the circle that the belt describes decreases or increases. The parts listed are CVT actuators. And everything is controlled by electronics based on information from numerous sensors.

The principle of operation of the variator

Stepless CVT transmission device

So, if the diameter of the driving pulley is maximum (its cones will be located as close to each other as possible), and the driven one is minimal (its cones will diverge as much as possible), then this means that the “highest gear” is on (corresponding to 4th or 5th transmission in a conventional transmission). Conversely, if the diameter of the driven pulley is minimal (its cones will diverge), and the driven pulley is maximum (its cones will close), then this corresponds to the “lowest gear” (the first in a traditional transmission).

Due to the design features of the design, the variator can only be used on relatively small machines (with an internal combustion engine power of up to 220 hp). This is due to the great effort that the belt experiences during operation. The process of operating a car with a CVT transmission imposes some restrictions on the driver. So, you can’t start abruptly from a place, drive for a long time at maximum or minimum speed, tow a trailer, or drive off-road.

Pros and cons of CVT boxes

Like any technical device, CVTs have their advantages and disadvantages. But in fairness, it must be taken into account that at present, automakers are constantly improving this transmission, so over time the picture will most likely change, and CVTs will have fewer shortcomings. However, today the CVT gearbox has the following pros and cons:

| Advantages | Disadvantages |

| The variator provides a smooth acceleration without jerks, typical for a manual or automatic transmission. | The variator is today installed on a car with an internal combustion engine power of up to 220 hp. This is due to the fact that very powerful motors have an excessive effect on the drive belt (chain) of the variator. |

| Higher efficiency. Thanks to this, fuel is saved, and the power of the internal combustion engine is transferred to the executing mechanisms faster. | The variator is very sensitive to the quality of the gear oil. usually, you need to buy only original high-quality oils, which are much more expensive than their budget counterparts. In addition, you need to change the oil more often than in a traditional transmission (about every 30 thousand kilometers). |

| Significant fuel economy. It is the result of high efficiency and a smooth increase in engine speed and speed (in a traditional transmission, significant overrun occurs during gear changes). | The complexity of the variator device (the presence of "smart" electronics and a large number of sensors) leads to the fact that at the slightest breakdown of one of the many nodes, the variator will be automatically switched to emergency mode or disabled (forced or emergency). |

| High environmental friendliness, which is the result of lower fuel consumption. And this means that cars equipped with a CVT meet modern high European environmental requirements. | The complexity of the repair. Often, even minor problems with the operation or repair of the variator can lead to a situation where it is difficult to find a workshop and specialists to repair this unit (this is especially true for small towns and villages). And the cost of repairing a variator is much higher than traditional manual or automatic transmissions. |

| The electronics that controls the variator always selects the optimal operating mode. That is, the transmission always works in the most gentle mode. Accordingly, this has a positive effect on the wear and service life of the unit. | A trailer or other vehicle cannot be towed on a vehicle with a CVT. |

Possible operational problems

In practice, owners of vehicles equipped with a CVT transmission face three main problems.

- Cone bearing wear. The reason for this phenomenon is banal - contact with wear products (metal chips) or debris on the working surfaces. The car owner will be told about the problem by the hum that comes from the variator. This can happen on different runs - from 40 to 150 thousand kilometers. According to statistics, Nissan Qashqai is very guilty of this. in order to avoid such a problem, it is necessary to regularly change the gear oil (in accordance with the recommendations of most car manufacturers, this must be done every 30 ... 50 thousand kilometers).

Pressure reducing pump and valve

- Failure of the oil pump pressure reducing valve. This will be reported to you by jerks and twitches of the car, both during starting and braking, and during a calm uniform ride. The cause of the breakdown, most likely, will lie in the same wear products. Due to their appearance, the valve is wedged in intermediate positions. Consequently, the pressure in the system begins to jump, the diameters of the driving and driven pulleys are out of sync, because of this, the belt begins to slip. During repairs, the oil and belt are usually changed, and the pulleys are ground. Breakdown prevention is the same - change transmission oil and filters on time, and also use high-quality oils. Remember that CVT type gear oil must be poured into the variator (it provides the necessary viscosity and “stickiness”). CVT oil is distinguished by ensuring the stable operation of the “wet” clutch. In addition, it is more sticky, which provides the necessary adhesion between the pulleys and the drive belt.

- Operating Temperature Issues. The fact is that the variator is very sensitive to the operating temperature range, namely, to overheating. The temperature sensor is responsible for this, which, if the critical value is exceeded, puts the variator into emergency mode (sets the belt to the middle position on both pulleys). For forced cooling of the variator, an additional radiator is often used. in order not to overheat the variator, try do not drive at maximum or minimum speed for a long time. also do not forget to clean the CVT cooling radiator (if your car has one).

Additional information about the variator

Many experts believe that the CVT gearbox (variator) is the most advanced type of transmission to date. Therefore, there are all prerequisites for the fact that the variator will gradually replace the automatic transmission, as the latter confidently replaces the manual transmission over time. However, if you decide to buy a car equipped with a CVT, then you need to remember the following important facts:

- the variator is not designed for an aggressive driving style (sharp acceleration and deceleration);

- it is strongly not recommended to drive a car equipped with a variator for a long time at extremely low and extremely high speeds (this leads to serious wear of the unit);

- the variator belt is afraid of significant shock loads, so it is recommended to drive only on a flat surface, avoiding country roads and off-road;

- during winter operation, it is necessary to warm up the box, monitor its temperature. At temperatures below -30, it is not recommended to use the machine.

- in the variator, it is imperative to change the gear oil in a timely manner (and use only high-quality original oil).

Before buying a car with a CVT gearbox, you need to be prepared for the conditions of its operation. It will cost you more, but it is worth the pleasure and comfort that the CVT provides. Thousands of motorists today use CVT transmission, and their number is only growing.

Reviews of CVT gearbox

Finally, we have collected for you real reviews of car owners whose cars are equipped with a CVT. We present them to your attention so that you have the maximum clear picture of the appropriateness of the choice.

| Positive reviews | Negative feedback |

| You have to get used to the variator. I had a subjective impression that as soon as you let off the gas, the car stops much faster than on the machine (most likely, the engine brakes). This was unusual for me, I like to roll up to a traffic light. And of the pluses - on the 1.5 engine, the dynamics are freaky (not compared to the Supra, but compared to conventional cars with 1.5) and the fuel consumption is small. | Everyone who praises the variator, no one can sanely explain why it is better than modern, also smooth 6-7-speed real hydromechanics, that is, the answer is simple, nothing, even worse (written above in the article). It's just that these people bought a CVT not because it is better than an automatic, but because the car they decided to buy did not come with a real automatic. |

| A CVT is more economical than an automatic (I compare it not with a Selick, but with any other car with a 1.3 engine | The variator does not inspire hope. An interesting development, of course. But, given that the entire global auto industry is moving away from improving reliability in modern units, nothing can be expected from varicos (as well as from robots). Is it possible to switch to a consumer attitude towards a car: I bought it, drove it for 2 years under warranty, merged it, bought a new one. Which is what they are leading us to. |

| Pros - faster and more confident acceleration compared to automatics and mechanics (if the mechanics are not a master of sports in auto racing). Profitability. (Fit-5,5 l, Integra-7 l, both on the highway) | Why do you need a variator when a “classic” automatic machine was invented long ago - smooth and super reliable? Only one option suggests itself - in order to reduce reliability and weld on the sale of spare parts. And so like, 100 thousand. the car drove - everything, it's time to go to the trash. |

| Last winter I drove a Civic with a CVT, there were no problems on ice. The variator is really more economical and more dynamic than the machine. The main thing is that you get it in good condition. Well, a little more expensive service is the price for driving pleasure. | In short, the variator = hemorrhoids, a marketing mulka for disposable cars. |

| The seventh year on the variator — the flight is excellent! | The old machine gun is reliable like ak47, nafik these varicos |

As you can see, most people who have tried to ride a CVT at least once, if possible, do not refuse further from this pleasure. However, it is up to you to draw conclusions.

Results

The variator, although more complex and expensive to maintain, is still today the best transmission for cars with internal combustion engines. And over time, the price of cars equipped with it will only decrease, and the reliability of such a system will grow. Therefore, the described restrictions will be removed. But today, do not forget about them, and use the machine in accordance with the manufacturer's recommendations, and then the SVT box will serve faithfully for a long time as well as the machine itself.