Securing the load to the vehicle is vital - securing the load securely in a few steps!

Content

Accident statistics speak for themselves: even today, despite laws and available tools, up to 20% of all accidents are due to improper load securing. With certain knowledge and a sense of responsibility, any cargo can be safely secured. Read in this overview about the grounds, the legal situation and the best ways to securely secure the load for the transported materials.

mass inertia

The force is equal to the product of the mass and the acceleration. While in motion, the mass maintains its direction. It takes a lot of effort to change its direction. The mass will oppose it with equal force. Moving a mass dynamically through multiple changes in direction requires significant effort.

Power movement in freight transport

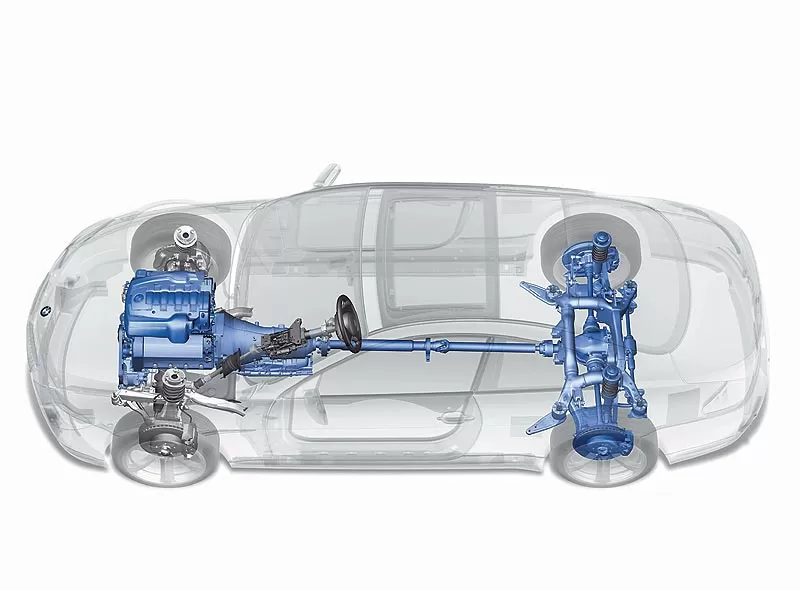

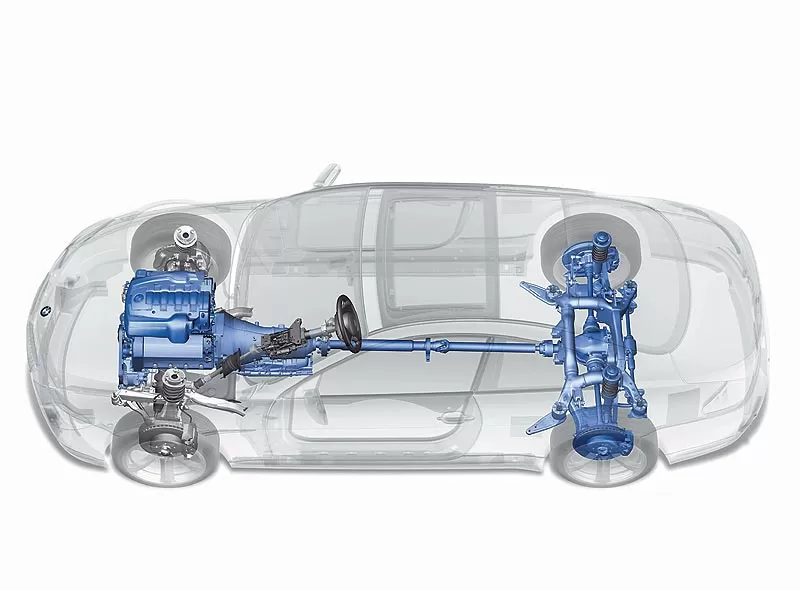

This becomes apparent when looking at the movement of cargo during transport. When accelerating from a stationary position, the vehicle drops slightly at the rear as a result of the load creating a force that opposes the direction of travel and pulls it in the other direction . When driving on a curve, the car deviates outward. The mass wants to go straight, pulling the car in the original direction. When braking, the car lowers onto the front axle. The load wants to continue moving, affecting the front suspension.

There is much more going on inside the vehicle: lashing straps, nets, cables, bolts and anything else that is used to secure a load absorb the movements of the load, safely transferring them to the suspension . At least ideally. In practice, cargo securing is often neglected, risking a fine.

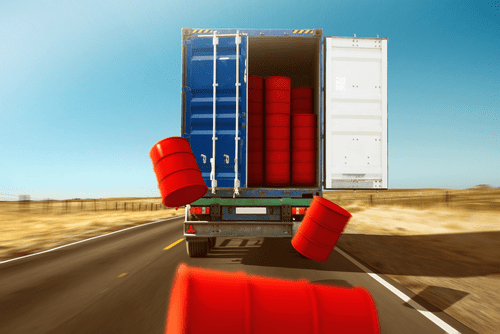

The lid is closed - is everything all right now? Wrong!

Many carriers operate on the principle: everything is good in the trunk . The goods cannot fall from the loading surface through the outer walls, so the load is securely secured. This is not the case. Load shifting can lead to hazardous situations, such as:

- drift and drift

– overturning

- breaching barriers

- breaking doors

- punching the driver's cab in case of an emergency stop.

Despite all this , loose loads are bound to be damaged indoors. Therefore, it is very important to securely tie and fix all goods.

Always depending on the type of cargo

The choice of cargo securing is always related to the type of cargo. Different types:

– liquids

– bulk materials

– general cargo

– sensitive goods

- Liquids in large quantities, it is best to transport in tank trucks, which is the easiest way to ensure the safety of liquids. However, driving with a large tank is a challenge, especially if the tank is not full. Fluid sloshing can be dangerous, especially when driving quickly around a curve.

- bulk material much easier to handle. Loose dry mass always creates friction forces inside. Sand, granulate, sand, scrap or screws - individual parts adhere to each other, preventing liquid from sloshing out. However, bulk material can move when there is a sudden change in load. Then the transport of the dry mass becomes a problem: unlike liquids, bulk material does not level out quickly . In the worst case, the vehicle may lose balance and tip over.

- General cargo everything is considered that can be placed on pallets, in cardboard boxes, boxes or separately on the loading bay. General cargo requires proper cargo securing. This is especially true for sensitive cargo. There are now many different mounts and straps available that make it much easier to safely transport even the most fragile materials to their destination.

- The logistics sector offers a variety of vehicles to safely transport almost any kind of cargo. The most common vehicles are:– Open semi-trailers for transportation of bulky piece cargo.

– Open dump trucks for bulk materials.

– Tank trucks for liquids.

– Platform trolleys for general cargo, containers or individual items.

– Vans or general cargo vans with special protection requirements.

– Trucks for special transportation.It is always important to choose the right truck for transporting cargo. Of course, you can try transporting water on a dump truck. The question remains how many of them reach their destination. Or you can try filling the van with sand - provided you've found a way to adequately unload the load. Luckily, logistics service providers have the right containers, trucks, and load securing equipment.

Cargo security for everyone

The following products are common for securing cargo:

- fastening straps

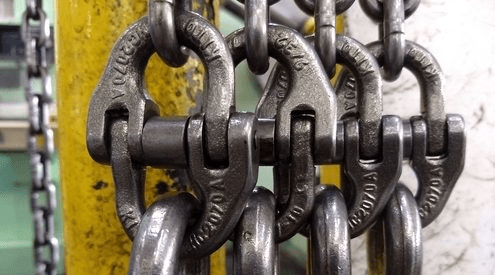

– chains

- bolts

- nets and tarps

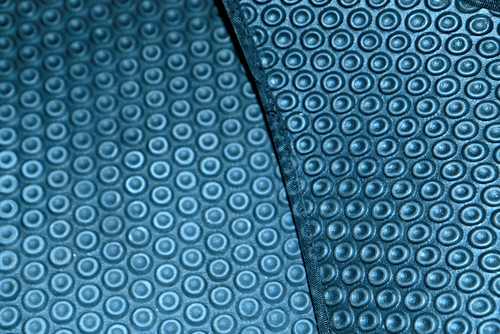

- anti-slip mats

– barriers

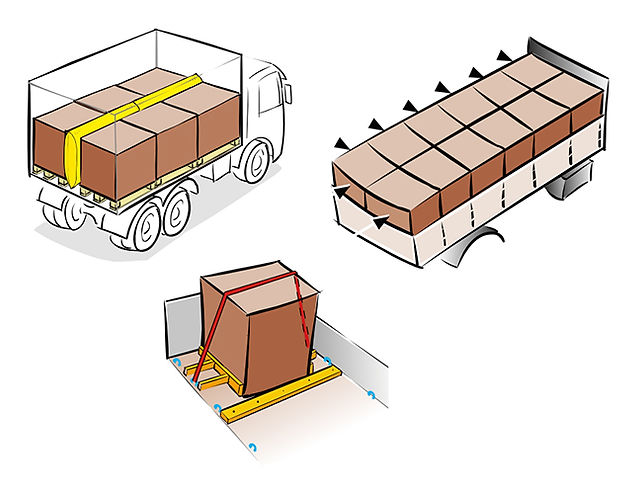

These products hold the load in place with a friction and shape lock.

- Friction locking means that the load is secured with force. When fastening a long load with the help of transversely tensioned tie-down straps, frictional fixation is provided, as well as shaped fixation. The friction lock works in the longitudinal direction: the pressing force of the tension belts and the friction of the underfloor, ideally equipped anti-slip mats prevent the load from shifting. From the side, the load is secured by physical barriers of transversely tensioned lashing straps. In order to fall sideways off the loading surface, the load must first break through the lashing straps.

- Fastening straps are the most common means of securing cargo. A wide range of protective equipment is available. The choice ranges from light but strong roof rack lashing straps to wide and very stable heavy load lashing straps. Machines and even large steel pipes can be securely fastened with lashing straps. Loads protruding more than one meter require a red warning flag to prevent drivers from crashing into the protruding load.

- For really massive loads cleaves better than belts, although they are much more difficult to handle.

However, chains promise maximum security.

- For special transport direct securing of the load on the loading platform is required , which usually requires special designs. In these cases, the truck is often equipped exclusively for its particular load. These solutions are often found in mechanical engineering and the automotive industry. This has the advantage of achieving maximum load securing with bolts and barriers. In addition, these solutions provide fast loading and unloading.

- Nets are a simple but effective means of preventing bulk and light cargo from scattering. . They are often mounted on open trucks or trash containers. The more granular the cargo, the smaller the network cells should be. Maximum safety is provided by a tarpaulin that provides additional weather protection.

- Barriers can be inserted or raised preventing cargo from shifting and offering additional attachment points for lashing straps.

Flexible barriers allow you to get the most out of your low loader, flatbed truck or van.

Load securing: consider the center of gravity

Load securing starts with the effective distribution of the load over the loading platform. The load is distributed in such a way that the center of gravity is at the most central point of the loading platform.

This is especially important for single axle trailers. . If the center of gravity is too far back, the trailer lifts the rear of the tractor by the drawbar . If the center of gravity is too far forward, the drawbar pushes down on the rear axle of the tractor, raising its front wheels. Both axle loads are inconvenient and significantly reduce driving safety. Deviations are unavoidable.

Also important: Always load and unload single axle trailers when they are coupled to a tractor. Drawbar and tractor prevent trailer tipping over .

Do without protection - an option

It is possible to transport large volumes of general cargo without additional cargo securing . If general cargo, such as palletized cartons, can be packed tightly into a stable loading area, no additional bracing is necessary. However, the cargo must be completely unloaded. As soon as voids appear inside the load, it can shift, which will require additional securing of the load.