Lifan 168F-2 engine: motoblock repair and adjustment

Content

The Chinese company Lifan (Lifan) is a large corporation that combines many industries: from small-capacity motorcycles to buses. At the same time, it is also an engine supplier for a large number of small companies producing agricultural machinery and small vehicles.

In accordance with the general tradition of Chinese industry, instead of their own developments, some successful model, usually Japanese, is copied.

The widely used 168F family engine, which is installed on a large number of push tractors, cultivators, portable generators and motor pumps, is no exception: the Honda GX200 engine served as a model for its creation.

General description of the Lifan device

The engine for the Lifan motoblock with a power of 6,5 hp, the price of which in various stores ranges from 9 to 21 thousand rubles, depending on the modification, has a classic design - it is a single-cylinder carburetor engine with a lower camshaft and a valve stem transmission (OHV scheme ).

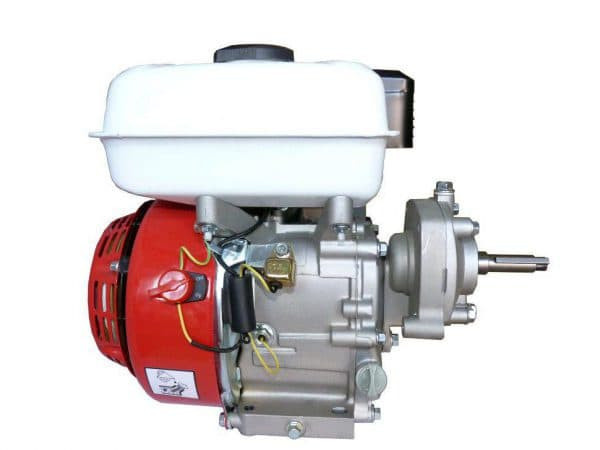

Lifan engine

Lifan engine

Its cylinder is made in one piece with the crankcase, which, despite the theoretical possibility of replacing the cast-iron sleeve, significantly reduces its maintainability when the CPG is worn out.

The engine is forced air-cooled, the performance of which is sufficient when working in hot weather, even under heavy loads.

The ignition system is transistorized, which does not require adjustments during operation.

The low compression ratio (8,5) of this engine allows it to run on AI-92 commercial gasoline of any quality.

At the same time, the specific fuel consumption of these engines is 395 g / kWh, i.e. for one hour of operation at a rated power of 4 kW (5,4 hp) at 2500 rpm, they will consume 1,1 liters of fuel per hour of operation at correct carburetor setting.

Currently, the 168F engine family includes 7 models with different configurations and connecting sizes, which have the following general characteristics:

- Cylinder size (bore/stroke): 68×54 mm;

- Working volume: 196 cm³;

- Maximum output power: 4,8 kW at 3600 rpm;

- Rated power: 4 kW at 2500 rpm;

- Maximum torque: 1,1 Nm at 2500 rpm;

- Fuel tank volume: 3,6 l;

- The volume of engine oil in the crankcase: 0,6 liters.

Modifications

Lifan 168F-2

Most economical configuration with 19 or 20 mm drive shaft. Manufacturer's price 9100 rubles.

Lifan 168F-2

Lifan 168F-2

For more information about the operation of the Lifan 168F-2 engine, see the video:

Lift 168F-2 7A

The engine variant is equipped with a lighting coil capable of supplying consumers with power up to 90 watts. This allows you to use it on various vehicles that require lighting: motorized towing vehicles, light swamps, etc. Price - 11600 rubles. Shaft diameter 20mm.

Lifan 168F-2 ignition circuit

The power unit has a conical shaft outlet, it differs from the base model only in the conical groove of the crankshaft tip, which ensures a more accurate and tight fit of the pulleys. Price - 9500 rubles.

Lifan 168F-2L

This motor has a built-in gearbox with an output shaft diameter of 22 mm and costs 12 rubles.

Motor Lifan168F-2R

The motor is also equipped with a gearbox, but with an automatic centrifugal clutch, and the size of the gearbox output shaft is 20 mm. The cost of the engine is 14900 rubles.

Lift 168F-2R 7A

As follows from the marking, this version of the engine, in addition to a gearbox with an automatic clutch mechanism, has a seven-ampere light coil, which brings its price to 16 rubles.

Lifan 168FD-2R 7A

The most expensive version of the engine at a price of 21 rubles differs not only in the diameter of the gearbox output shaft increased to 500 mm, but also in the presence of an electric starter. In this case, the rectifier required to charge the battery is not included in the scope of delivery.

Repair and adjustment, speed setting

Engine repair sooner or later awaits any push tractor, whether it be Cayman, Patriot, Texas, Foreman, Viking, Forza or some other. The procedure for disassembling and troubleshooting is simple and does not require special tools.

Engine repair

Engine repair

It should be noted that the manufacturer does not specify specific wear limits for troubleshooting engine components, so the following dimensions are given by analogy with other air-cooled four-stroke engines:

- Drain the oil from the crankcase and transmission (if equipped) by removing drain plugs and any remaining fuel from the gas tank.

- Remove the fuel tank, muffler and air filter.

- Disconnect the carburetor, which is attached to the cylinder head with two studs.

- Remove the recoil starter and fan shroud.

- Having fixed the flywheel with an improvised tool, so as not to damage the fan blades, unscrew the nut that holds it.

- After that, using a three-legged universal puller, pull the handlebar out of the landing cone.

- If the disassembly was caused by poor starting and a decrease in engine power, check if the keyway is broken, as in this case the flywheel will move, and the ignition timing, determined by the magnetic mark on it, will change.

- Remove the ignition coil and lighting coil, if any, on the engine.

- Having unscrewed the valve cover bolts, unscrew the four cylinder head bolts located under this cover, and remove the cylinder head. To check the valve adjustment, turn the combustion head upside down and fill it with kerosene.

- If kerosene does not appear in the inlet or outlet channel of the manifold within a minute, the adjustment of the valves can be considered satisfactory, otherwise they must be rubbed with abrasive paste on the seats or (if burnt ones are found) replaced.

- On models equipped with a transmission, remove its cover and remove the output shaft, then press the drive gear or sprocket (depending on the type of transmission) from the crankshaft. Replace gears with noticeable tooth wear.

- We unscrew the bolts that hold the rear cover around the perimeter and remove it, after which you can remove the camshaft from the crankcase.

- Having thus freed up space in the crankcase, unscrew the bolts connecting the bottom cover of the connecting rod to its body, remove the cover and the crankshaft.

- Push the piston together with the connecting rod into the crankcase.

If you find play in the bearings, replace them. Also, since the repair dimensions of the parts are not provided, they are replaced with new ones:

- Connecting rod: with increased to perceptible radial play in the crankshaft journal;

- Crankshaft: connecting rod journal stuck;

- Crankcase - with significant wear (more than 0,1 mm) of the cylinder mirror in the largest place;

- Piston: with mechanical damage (chips, scratches from overheating);

- Piston rings - with an increase in the gap in the junction of more than 0,2 mm, if the cylinder mirror itself does not have wear reaching the rejection limit, as well as with a noticeable waste of engine oil.

Lubricate all moving parts with clean engine oil before reassembly and clean soot-covered surfaces of the combustion chamber and piston crown to reduce heat stress on these areas. The engine is assembled in the reverse order of assembly.

For grinding grain, a special device is used - the Kolos grain crusher, which is produced at the Rotor plant. Here you can get acquainted with this inexpensive and reliable grain crusher.

On the domestic market of agricultural machinery, various options for cultivators are presented, not only of Russian, but also of foreign production. The Mantis cultivator has been a reliable machine for decades.

Snowmobile sleds are essential for comfortable winter travel over long distances. Follow the link to learn how to make your own sled.

When installing the camshaft, be sure to align the mark on its gear with the same mark on the crankshaft gear.

Cylinder cover

Cylinder cover

Evenly tighten the cylinder head bolts crosswise in two passes until the final tightening torque is 24 Nm. The flywheel nut is tightened with a torque of 70 N * m, and the connecting rod bolts - 12 N * m.

After mounting the engine, as well as regularly during operation (every 300 hours), it is necessary to adjust the valve clearances. Order of operations:

- Set the piston to top dead center on the compression stroke (since there are no marks on the flywheel, check this with a thin object inserted into the spark plug hole). It is important not to confuse compression TDC with exhaust TDC: the valves must be closed!

- After loosening the locknut, turn the nut in the middle of the rocker arm to adjust the appropriate valve clearance, then fix the locknut. The clearance adjusted with a feeler gauge should be 0,15 mm on the intake valve and 0,2 mm on the exhaust valve.

- Having cranked the crankshaft exactly two turns, recheck the clearances; their deviation from the established ones can mean a large play of the camshaft in the bearings.

Salyut 100 with 168F engine - description and price

Of the many units that have a 6,5 hp Lifan engine, the Salyut-100 push tractor is the most common.”

Greeting 100

Greeting 100

The production of this light leg tractor began in the Soviet Union, in accordance with the then tradition of loading military-industrial complex enterprises with additional production of the so-called "consumer goods" and continues to this day. Moscow object. Salute of OAO NPC Gas Turbine Engineering.

Complete with a Lifan 168F engine, such a push tractor costs about 30 rubles. It has a relatively low weight (000 kg), which, combined with an average engine power indicator for this class of equipment, makes it unsuitable for plowing with a plow without additional weight.

But for cultivation it is quite good thanks to the sectional cutters included in the kit, which allow you to change the working width from 300 to 800 mm, depending on the severity of the soil.

The big advantage of the Salyut-100 push tractor over various classmates is the use of a gear reducer, which is more reliable than a chain one. The gearbox, which has two speeds forward and one speed reverse, is additionally equipped with a reduction gear.

Motoblock "Salyut" does not have a differential, but the narrow wheelbase (360 mm) in combination with low weight does not make turns laborious.

Motoblock complete set:

- Section cutters with protective discs;

- Track extension bushings;

- Opener;

- Rear hinge bracket;

- Tools;

- Spare belt.

In addition, it can be equipped with a plow, blade, snow blower, metal grouser wheels and other equipment, widely compatible with most domestic push tractors.

The choice of engine oil that can be poured into the engine of a walk-behind tractor

Engine oil for a push tractor Salyut with a Lifan engine should only be used with a low viscosity (viscosity index at high temperatures no more than 30, in hot conditions - 40).

This is due to the fact that, to simplify the design of the engine, there is no oil pump, and lubrication is carried out by spraying oil as the crankshaft rotates.

A viscous engine oil will cause poor lubrication and increased engine wear, especially in its more stressed sliding friction pair on the lower big end of the connecting rod.

At the same time, since the low boost level of this engine does not impose high requirements on the quality of engine oil, the cheapest automotive oils with a viscosity of 0W-30, 5W-30 or 5W-40 can be used for a long time. - service life in the heat.

As a rule, oils of this viscosity have a synthetic base, but there are also semi-synthetic and even mineral oils.

At about the same price, air-cooled semi-synthetic motor oil is preferred over mineral oil.

It forms less high-temperature deposits that impair heat removal from the combustion chamber and the mobility of the piston rings, which is fraught with engine overheating and loss of power.

In addition, due to the simplicity of the lubrication system, it is imperative to check the oil level before each start-up and maintain it at the upper mark, while changing the engine oil once a year or every 100 hours of engine operation.

On a new or remanufactured engine, the first oil change is done after 20 hours of operation.

Conclusion

Therefore, the Lifan 168F family of engines is a good choice when choosing a new pusher or when it is necessary to replace the power unit with an existing one: they are quite reliable, and due to the wide distribution of spare parts for them, it is easy to find affordable ones.

At the same time, engines of all modifications are easy to repair and maintain and do not require high qualifications for these works.

At the same time, the price of such an engine (9000 rubles in the minimum configuration) is somewhat higher than that of unnamed Chinese manufacturers imported by various manufacturers under their own brands (Don, Senda, etc.), but noticeably lower than that of the original Honda engine.