The best primers for galvanized car metal

Content

Novice car mechanics often wonder what kind of mixture to buy. Even knowing the composition of the solution that needs to be primed with galvanized car parts, it is not always possible to decide on the choice of brand. There are many manufacturers on the market offering various automotive primers. To help the craftsmen, we have compiled the top 3 primers for auto galvanizing.

The primer is an important component for car body repair made of galvanized metal. The quality of the coating with the finishing paint and varnish material depends on the solution used.

Primers for body repair: purpose

A primer is a liquid composition necessary to prepare the surface of a car for applying paint. Inexperienced car painters often make mistakes when they begin to prime a galvanized car without trying to figure out the purpose of the mixture. Each material differs not only in brand and price, but also in composition, which affects certain properties of the coating. Depending on the type of primer for car processing, it is used to:

- ensuring strong adhesion of metal to paint;

- increase of anticorrosive properties;

- filling pores and small scratches left after grinding the machine;

- separation of incompatible layers, which, when combined, can give a reaction - swelling of the paint.

Primer types

Today, a wide range of mixtures is presented on the car market, with the help of which galvanizing equipment is presented. All of them are divided into two large groups:

- primary (primers);

- secondary (fillers).

Galvanizing with primary primers is relevant for factories where cars are produced. Secondary ones are more often used in auto repair shops when repairing vehicles.

Primer types

Primary soils

The primer is used to coat the "bare" metal, the most susceptible to corrosion. The primary primer is applied before puttying or a layer of other liquid solution. It performs a protective function, preventing the appearance and growth of rust. Also, the primer for a bare galvanized car becomes an adhesive "intermediary", which provides a strong adhesion of the metal to the subsequent layer of paintwork.

Secondary soils

The filler serves as a filler and leveler. Its main task is to fill the pores and craters formed during puttying, as well as to eliminate the consequences of unsuccessful grinding, to level the joints and transitions. Secondary primers have good adhesion and corrosion resistance, but these characteristics are lower compared to primers.

Features of galvanizing primer

The steel surface has a smooth texture that does not lend itself well to paint. All masters know that it is necessary to prime the galvanized metal of a car in order to ensure its adhesion to the paintwork. In addition, steel sheets themselves have high corrosion resistance, but in the event of a small accident, zinc is easily destroyed. As a result, the car is unevenly protected from rust, which further leads to the appearance of foci of corrosion.

An important feature of the primer for galvanized car metal is that it is first necessary to reduce the protective functions of the coating by etching it with acid. In this case, the primer will be performed as efficiently as possible.

How to prime galvanized car metal

According to the technology, the bare metal surface must be treated with a suitable primer mixture. After that, it is possible to carry out the finishing coating with paints and varnishes, which also need to be properly selected.

Primer for galvanized metal

There are commercially available primers designed specifically for zinc surfaces. Considering that the car is operated in aggressive conditions, a galvanized epoxy-based primer should be selected for a high-quality coating. It is durable, resistant to mechanical damage, has high moisture resistance. There are also two-component primer-enamels that are applied to the "bare" metal and at the same time serve as a topcoat.

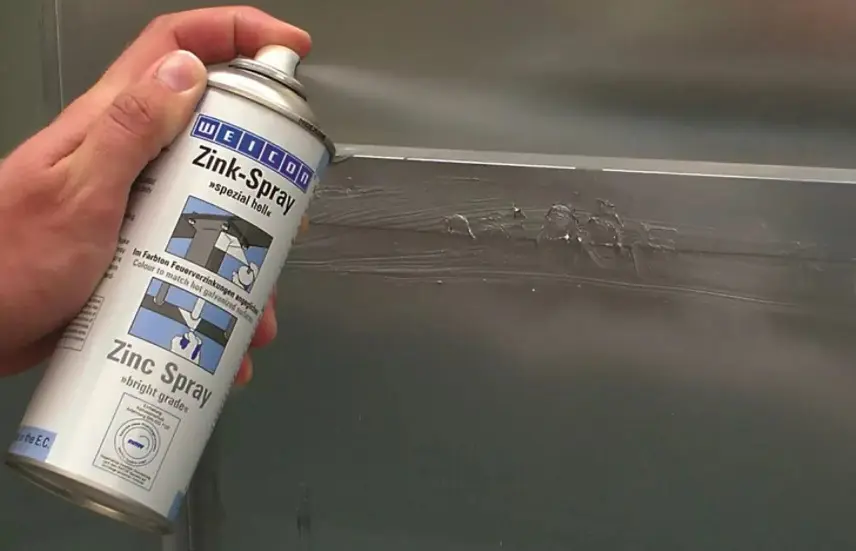

Before priming, it is important to clean the surface from dirt and dust. The metal must be dry so that no chemical reactions occur during operation that can adversely affect the coating. The primer solution is convenient to use in the form of an aerosol.

Paint for galvanized surfaces

It is unacceptable to cover the metal with oil or alkyd paints and varnishes. Their interaction with the zinc surface will lead to oxidation, a decrease in adhesive properties, which will cause swelling and peeling of the paint. It is also not recommended to use mixtures that contain copper, tin, antimony. They significantly reduce the durability of the painted surface. For galvanized metal, it is advisable to use paint:

- powder;

- urethane;

- acrylic.

The best is powder paint, made on the basis of epoxies and polymers. It is used in production for painting cars, as it has high strength and durability. The only disadvantage of the coating is that it is difficult to decorate.

Phosphate soil

The best primers for galvanized metal

Novice car mechanics often wonder what kind of mixture to buy. Even knowing the composition of the solution that needs to be primed with galvanized car parts, it is not always possible to decide on the choice of brand. There are many manufacturers on the market offering various automotive primers. To help the craftsmen, we have compiled the top 3 primers for auto galvanizing.

"ZN-Primer" automotive epoxy quick-drying for steel body panels and welds

The primer is ideal for galvanized cars for painting, providing high metal protection against corrosion and good adhesion. The mixture is used for the treatment of car bodies, water equipment and parts subject to rust. The composition is distinguished by the absence of smudges when applied vertically, fast drying speed, compatibility with various types of car enamels.

| Manufacturer | Hi Gear |

| appointment | Защита от коррозии |

| Application surface | Zinc |

| Volume | 397 g |

Aerosol primer HB BODY 960 light yellow 0.4 l

Two-component primer suitable for application on zinc, aluminum, chrome, and most often used for car bodywork. Due to the acid content in the composition, the mixture is used as a primer. But, according to reviews, auto repairers prefer to cover a galvanized car with this primer in order to fill pores and small cracks with a solution. After applying the agent to the damaged area, a film is formed that blocks the growth of indelible rust. After using the primer mixture, it is recommended to apply additional enamel, which will be a separator between the acid layer and the top coat.

| Manufacturer | HB Body |

| appointment | Corrosion protection, pore filling |

| Application surface | Aluminium, zinc, chrome |

| Volume | 0,4 l |

Primer for galvanized and ferrous metal NEOMID 5 kg

One-component primer, the main purpose of which is to protect the surface from rust. It is supplied ready-made, so there is no need to mix the mixture with hardeners and other substances before use. The soil has high quality characteristics and is in demand among professional craftsmen. The only negative is the drying speed - 24 hours.

| Manufacturer | Neomid |

| appointment | Защита от коррозии |

| Application surface | Zinc, ferrous metal |

| Volume | 10 kg |

Criterias of choice

When choosing a primer for car processing, it is recommended to consider:

- durability of the updated coating;

- resistance to environmental influences;

- adhesive properties;

- chemical activity;

- resistance to moisture and frost.

How to paint galvanized steel so that it does not peel off as long as possible

Before using primer and paint on galvanized car metal, prepare the surface:

- Carry out cleaning of car parts from dust, dirt, traces of corrosion. To do this, use sandblasting equipment, sandpaper, soapy water.

- Then degrease the surface with a low concentration of phosphoric acid or a mixture of acetone and toluene in a ratio of 1 to 1. It is permissible to degrease the coating with kerosene, white spirit, chlorine-containing bleach.

Immediately after performing these steps and drying the applied products, paint the surface. It is recommended to finish painting within 30 minutes after you have primed the car. This will increase the adhesive properties of the material, as well as provide a high-quality coating. To achieve maximum results, it is recommended to apply 2-3 layers of topcoat.