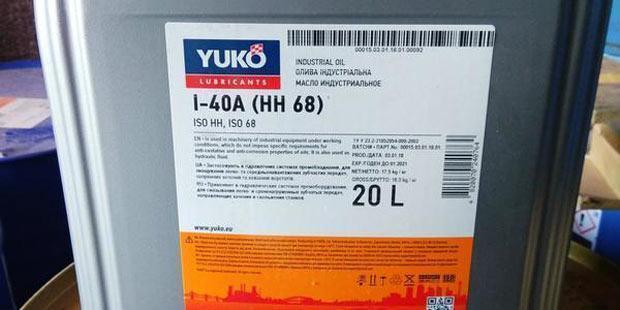

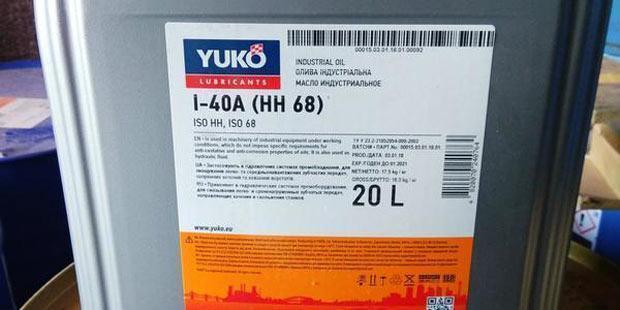

Industrial oils I-40A

Industrial oil I-40A refers to multi-purpose lubricants, which are recommended for use in parts and friction units in the absence of a significant corrosive effect of the environment. The technical conditions for the production of oil must comply with the requirements of GOST 20799-88.

physical and chemical indicators

Basic characteristics of I-40A oil:

- Density at room temperature, kg/m3 - 810 ± 10.

- Kinematic viscosity, mm2/ s, at a temperature of 50 °C - 35… 45.

- Kinematic viscosity, mm2/ s, at a temperature of 100 ° C, not lower than - 8,5.

- Flash point °C, not lower - 200.

- Thickening temperature, °C, not lower than -15.

- Acid number, in terms of KOH - 0,05.

- Coke number - 0,15.

- Maximum ash content,% - 0,005.

Fresh industrial oil I-40A (there are also designations oil IS-45 and machine oil C) should be supplied to consumers only in the state of preliminary distillate purification and without additives.

GOST 20799-88 also provides that when used as a hydraulic fluid, this brand of oil should be tested for its stability at varying operating pressures. Mechanical stability is determined according to the indications of the shear strength of the lubricating layer, which is located in the technological gap between adjacent friction surfaces.

The second indicator of mechanical stability is the oil viscosity recovery time, which is set according to the GOST 19295-94 method. Upon additional request, I-40A oil is also tested for colloidal stability. The test consists of determining the amount of oil that has been pressed out of the original grease using a calibrated penetrometer. This indicator is necessary for the operating conditions of the oil at sharply changing external temperatures.

The international analogue of this lubricant is Mobil DTE Oil 26, produced according to ISO 6743-81, as well as oils manufactured by other companies that meet the requirements of the standard.

Application

I-40A oil is considered a medium-viscosity lubricant, which is best used in heavily loaded machines and mechanisms where significant contact pressures develop. The absence of specific additives makes it possible to use this oil also as a diluent: both for more low-viscosity lubricants (for example, I-20A or I-30A), and for oils with increased viscosity (for example, I-50A).

Excellent oxidation stability helps reduce equipment downtime and maintenance costs by promoting system cleanliness and deposit reduction, extending oil and oil filter life.

Improved anti-wear and corrosion protection of system components using various types of routine maintenance helps to extend the life of technical system components and increase their performance. During manufacture, I-40A oil is treated with demulsifiers, so this lubricant protects equipment well from water ingress to rubbing surfaces.

Rational areas of use of I-40A oil:

- Friction systems, during which there is a risk of accumulation of surface deposits.

- Hydraulic systems requiring high load capacity and wear protection.

- Machines and mechanisms that are constantly operated in a corrosive environment.

- Metalworking equipment operating at elevated process pressures.

Oil successfully shows itself as a component of the working fluid in the electroerosive machining of metals and alloys.

The price of industrial oil I-40A depends on the manufacturer and packaging of the product:

- When packing in barrels with a capacity of 180 liters - from 12700 rubles.

- When packing in canisters with a capacity of 5 liters - from 300 rubles.

- When packing in canisters with a capacity of 10 liters - from 700 rubles.

Watch this video on YouTube