Oil pump on the VAZ 2106: principle of operation, adjustment, repair

Content

VAZ 2106 cars have been produced in Russia since 1976. During this time, much has changed in the design of the machine, however, initially well-chosen mechanisms are used for the “six” to this day. The power unit, body, suspension - all this remained unchanged. A special role in the operation of the internal combustion engine is played by the lubrication system, which since 1976 has remained a chain one. There are practically no such mechanisms on modern cars, so the owners of the "sixes" should know exactly how the lubrication system works and what needs to be done in case of breakdowns.

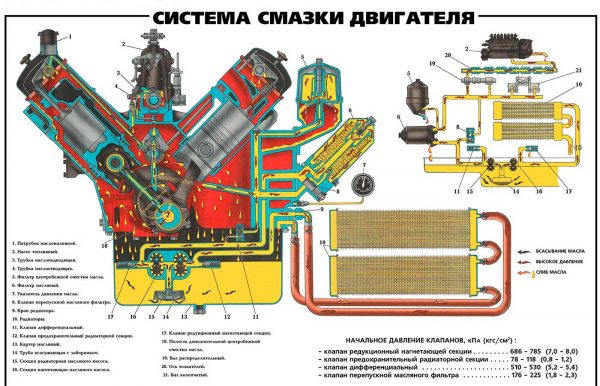

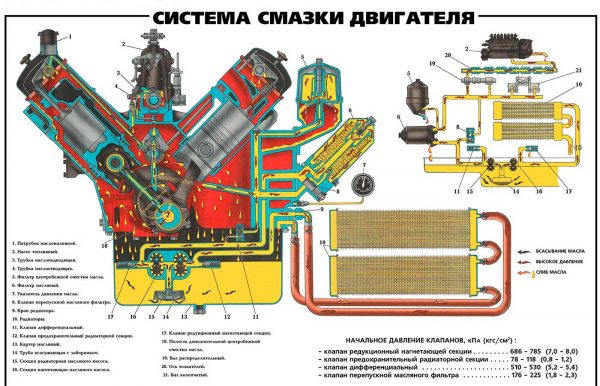

Engine lubrication system VAZ 2106

The lubrication system of any engine is a complex of various elements and parts that allow high-quality maintenance of the power unit. As you know, the key to the success of the motor is a full-fledged lubrication so that the moving parts do not wear out as long as possible.

On VAZ 2106 vehicles, the lubrication system is considered combined, since the lubrication of the rubbing parts of the motor is carried out in two ways:

- through splashing;

- under pressure.

The minimum oil pressure in the system at an engine operating temperature of 85-90 degrees should be 3,5 kgf / cm2, maximum - 4,5 kgf / cm2.

The total capacity of the entire system is 3,75 liters. The lubrication system on the "six" consists of the following components, each of which consumes or conducts its own part of the oil:

- crankcase for liquid;

- level indicator;

- pumping unit;

- oil supply pipe to the engine;

- oil filter element;

- valve;

- oil pressure sensors;

- highways.

The oil pump plays the most important role in the operation of the entire lubrication system. This device is designed to provide continuous circulation of oil to all components of the system.

Oil pump

On VAZ 2106 cars, a gear pump is installed, on the cover of which there are already an oil receiver and a pressure reducing valve mechanism. The body structure is a cylinder with gears mounted on it. One of them is the leading (main), the other moves due to inertial forces and is called the driven one.

The device of the pump itself is a serial connection of a number of units:

- metal case;

- oil receiver (a part through which oil enters the pump);

- two gears (driving and driven);

- pressure reducing valve;

- stuffing box;

- various pads.

The resource of the oil pump on the VAZ 2106 is approximately 120-150 thousand kilometers. However, the gland and gaskets can fail much earlier, which will lead to premature replacement of the device.

The sole function of the oil pump is to supply oil to all parts of the engine. We can say that the functioning of the motor and its resource depend on the performance of the pump. Therefore, it is important to monitor what kind of oil is poured into the engine, and in what mode the oil pump operates.

Principle of operation

On the "six" the oil pump is started using a chain drive. This is a rather complicated starting system, and therefore repairing and replacing the pump can cause some difficulties.

The principle of operation is based on the following stages of starting the pump:

- After the ignition is turned on, the first gear of the pump starts.

- From its rotation, the second (driven) gear begins to rotate.

- Rotating, the gear blades begin to draw oil through the pressure reducing valve into the pump housing.

- By inertia, the oil leaves the pump and enters the motor through the lines under the required pressure.

If, for a number of reasons, the oil pressure is higher than the norm for which the pump is designed, then part of the liquid is automatically redirected to the engine crankcase, which helps to normalize the pressure.

Thus, the circulation of oil is carried out by means of two rotating gears. At the same time, it is very important that the entire pump device is completely sealed, since the slightest oil leak can significantly reduce the operating pressure in the system and impair the quality of motor lubrication.

Bypass (reducing) valve

The driving and driven gears rarely break, as they have the simplest design. In addition to oil seals and gaskets, there is another component in the pump device that can fail, which will have disastrous consequences for the engine.

We are talking about a pressure reducing valve, which is sometimes called a bypass valve. This valve is needed in order to maintain the pressure in the system that was created by the pump. After all, an increase in pressure can easily lead to breakdown of parts of the motor, and low pressure in the system does not allow high-quality lubrication of rubbing parts.

The pressure reducing (bypass) valve on the VAZ 2106 is responsible for controlling the oil pressure in the system. If necessary, it is this valve that can weaken or increase the pressure so that it meets the norm.

The increase or decrease in the existing pressure is made by simple actions: either the valve closes or opens. Closing or opening of the valve is possible due to the bolt, which presses on the spring, which, in turn, closes the valve or opens it (if there is no pressure on the bolt).

The bypass valve mechanism consists of four parts:

- small body;

- valve in the form of a ball (this ball closes the passage for supplying oil, if necessary);

- spring;

- stop bolt.

On the VAZ 2106, the bypass valve is mounted directly on the oil pump housing.

How to check the oil pump

An emergency light will warn the driver that there are some problems in the operation of the oil pump. In fact, if there is enough oil in the system, and the lamp still continues to burn, then there are definitely malfunctions in the operation of the oil pump.

To identify a pump malfunction, you can not remove it from the car. It is enough to measure the oil pressure and compare them with the norm. However, it is more expedient to carry out a complete check of the device by removing it from the machine:

- Drive the VAZ 2106 onto an overpass or viewing hole.

- First of all, turn off the power to the car (remove the wires from the battery).

- Drain the oil from the system (if it is new, then you can reuse the drained fluid later).

- Unscrew the nuts securing the suspension to the cross member.

- Remove engine crankcase.

- Dismantle the oil pump.

- Disassemble the pump device into components: dismantle the valve, pipes and gears.

- All metal parts must be washed in gasoline, cleaned of dirt and wiped dry. It will not be superfluous to purge with compressed air.

- After that, you will need to inspect the parts for mechanical damage (cracks, chips, wear marks).

- Further check of the pump is carried out using probes.

- The gaps between the gear teeth and the pump walls should be no more than 0,25 mm. If the gap is larger, then you will have to change the gear.

- The gap between the pump housing and the end side of the gears should not exceed 0,25 mm.

- The gaps between the axes of the main and driven gears should be no more than 0,20 mm.

Video: checking the oil pump for serviceability

Oil pressure adjustment

Oil pressure should always be correct. Increased or underestimated pressure characteristics always negatively affect the operation of the internal combustion engine. So, for example, a lack of pressure may indicate severe wear or contamination of the oil pump, and excessive oil pressure may indicate a jamming of the pressure reducing valve spring.

In any case, you will need to check several basic mechanisms of the VAZ 2106 in order to find the cause of high / low pressure and adjust the operation of the lubrication system:

- Make sure that the engine is filled with high-quality oil, the level of which does not exceed the norm.

- Check the condition of the oil drain plug on the sump. The plug must be fully tightened and not leak a drop of oil.

- Check the operation of the oil pump (most often the gasket fails, which is easy to replace).

- Check the tightness of the two oil pump bolts.

- See how dirty the oil filter is. If the pollution is strong, you will have to replace it.

- Adjust the oil pump relief valve.

- Inspect oil supply hoses and their connections.

Photo: the main stages of adjustment

-

- There should be no oil leaks around the plug.

-

- All parts of the mechanism must function normally.

-

- The spring and other parts of the valve must not have visible damage.

Do-it-yourself oil pump repair

The oil pump is considered a mechanism that even an inexperienced driver can repair. It's all about the simplicity of design and the minimum number of components. To repair the pump you will need:

- open-end wrenches for "10" - 2 pcs.;

- ruler - 1 pc.;

- probes - a set;

- vise.

To repair the oil pump, you need to remove it from the car and disassemble it. It is best to disassemble the part in order:

- Disconnect the oil supply pipe from the pump housing.

- Remove three mounting bolts.

- Disconnect the pressure reducing valve.

- Remove spring from valve.

- Remove the cover from the pump.

- Remove the main gear and shaft from the housing.

- Next, remove the second gear.

Photo: the main stages of repair work

-

- After disconnection, oil may leak from the nozzles, so it is recommended to prepare rags in advance

-

- The pump is fixed with only three bolts, so it will be easy to remove it

-

- It is better to disassemble the pump in a clean environment to prevent dust from entering inside

This completes the disassembly of the oil pump. All removed parts must be washed in gasoline (kerosene or common solvent), dried and inspected. If the part has a crack or signs of wear, it must be replaced without fail.

The next stage of repair work is to adjust the gaps:

- between the axis and the second gear, the gap should be no more than 0,1 mm (must be measured with a ruler), if the gap is larger, then the second gear must be replaced;

- between the teeth of two gears should be no more than 0,25 mm;

- the gap between the upper part of the gears and the cover is no more than 0,2 mm;

- the gap between the pump casing and the outer part of any gear is not more than 0,25 mm.

After checking the parameters, you can proceed to the final stage of the repair - checking the spring on the valve. It is necessary to measure the length of the spring in a free position - it should be no more than 3,8 cm in length. If the spring is badly worn, it is recommended to replace it.

Video: how to correctly measure gaps

Without fail, during the repair, the oil seal and gaskets are changed, even if they are in satisfactory condition.

After replacing all worn parts, the oil pump must be assembled in the reverse order.

Video: installing an oil pump on a VAZ 2106

Watch this video on YouTube

Oil pump drive

The oil pump drive is the part that needs to be mentioned separately. The fact is that the duration of the entire motor depends on it. The drive part of the oil pump itself consists of several parts:

- parasitic shaft;

- intermediate gear;

- small shaft;

- big shaft.

Most cases of oil pump failure are associated precisely with a drive failure, or rather, with wear of the gear splines.. Most often, the splines “lick off” when starting the car in winter, in which case it is impossible to start the engine again.

Gear wear is an irreversible process during long-term operation of the machine. If the gear teeth begin to slip, then the pressure in the oil system will be lower than the working one. Accordingly, the engine will not receive the amount of lubrication that it needs for regular operation.

How to replace the pump drive

Replacing the drive gear is not an easy procedure, but after careful preparation, you can remove the drive and repair it:

- Remove the ignition distributor.

- To remove the intermediate gear, you will need a special puller. However, you can get by with a simple wooden stick with a diameter of about 9–10 mm. The stick must be hammered into the gear with a hammer, then scroll it clockwise. The gear then easily comes out.

- In place of the worn gear, install a new one using an ordinary stick.

- Install the ignition distributor.

Video: replacing the oil pump drive mechanism

Watch this video on YouTube

What is a "boar" and where is it located

As part of the mechanisms of the VAZ 2106 there is a shaft, which is called the "boar" (or "pig"). The shaft itself drives the vehicle's oil pump, as well as the petrol pump and sensors. Therefore, if the "boar" suddenly fails, then the machine ceases to function normally.

The intermediate shaft is located in the engine compartment of the VAZ 2106 on the front side of the cylinder block. On the “six”, the “boar” is launched using a chain drive. This shaft has an extremely simple structure - only two necks. However, if the bushings on the necks are badly worn, the operation of the oil pump and other mechanisms will be difficult. Therefore, when checking the pump, they usually look at the operation of the “boar”.

Work with the oil pump on the VAZ 2106 can be done on your own in the garage. The main feature of domestic "sixes" lies precisely in the unpretentiousness of maintenance and simplicity of design. And it is allowed to repair the oil pump and adjust the pressure in the system on your own, since there are no special requirements for this procedure.