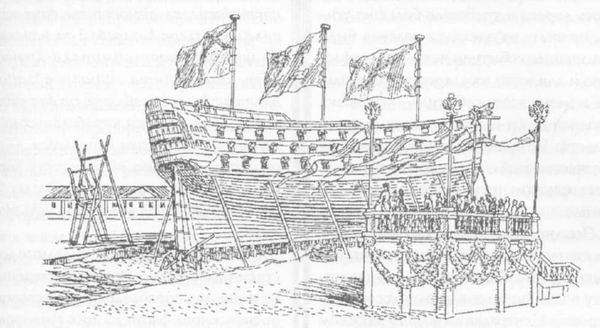

Melitopol - the first ship from the slipway

Melitopol, the first dry cargo ship and the first Polish side boat.

Photo “Sea” 9/1953

Melitopol - the first sea vessel from Stochni im. Paris Commune in Gdynia. It was built and launched by a new method - along the side ramp. The ship sailed sideways towards the pool, which was then a great sensation and a phenomenon in our shipbuilding.

In the early 50s, no one in Poland had heard of a side ramp. Vessels were built and launched on longitudinal stocks or in floating docks. Smaller objects were transferred to the water using cranes.

From the very beginning of its existence, the Gdynia shipyard has been repairing various ships and restoring sunken ships. Thus, she gained enough experience to be able to start the production of new units. This was facilitated by the growing demand for its products in shipping and fishing.

The signing of a contract with the eastern neighbor for the construction of a large series of ships changed the previous assumptions. It was necessary to provide the shipyard with equipment for the production of new units and adapt existing production facilities for this purpose. The construction of equipment for berths with steam, water, pneumatic, acetylene and electric installations has begun. At the same time, appropriate cranes were installed on them. A classic track has been laid in the attic of the hull hull, and the entire workshop is equipped with overhead cranes, straightening and bending rollers and welding equipment. In the large hall, three bays were created for the workshop for the manufacture of hull sections.

After much thought and discussion, it was also decided to choose one of two concepts: to build a longitudinal ramp in the field to the north of the workshop building or foundations for the floating dock. However, both of them had some common drawbacks. The first was that materials leaving the warehouses for processing would be transported through the same gates used to transport finished hull parts. The second drawback was the long time for hydraulic engineering work on construction sites, including wild and undeveloped lands.

Engineer Alexander Rylke: In this difficult situation, Ing. Kamensky turned to me. I addressed him not as a professor, since I was in charge of the department of ship design, and not the technology of their construction, but to a senior colleague and friend. We have known each other for almost 35 years. We graduated from the same university in Kronstadt, we got to know each other better in 1913, when, having almost 5 years of professional work behind me, I started working at the Baltic Shipyard in St. Petersburg, and he was doing postgraduate studies there. Later we met in Poland, he worked in the Naval workshops in Oksivie, and I was in the naval headquarters in Warsaw, from where I often came to Gdynia on business. Now he invited me to the "Thirteen" [from the then name of Shipyard No. 13 - approx. ed.] to present me with the whole difficult question. At the same time, he sharply shook his nose at the proposals made at the shipyard.

I reviewed the situation in detail.

“Well,” I said as a result of this “look around”. - It's clear.

- Which? - He asked. - Ramp? Doc?

- Neither one nor the other.

- So what?

- Side launch only. And this is when “jumping”.

I explained to him exactly how I imagine all this. After 35 years of nurturing and maturing my "seed", I finally saw the soil in which it could and should bear fruit.