Mercedes-Benz GLC F-Cell combines 24 years of experience

Content

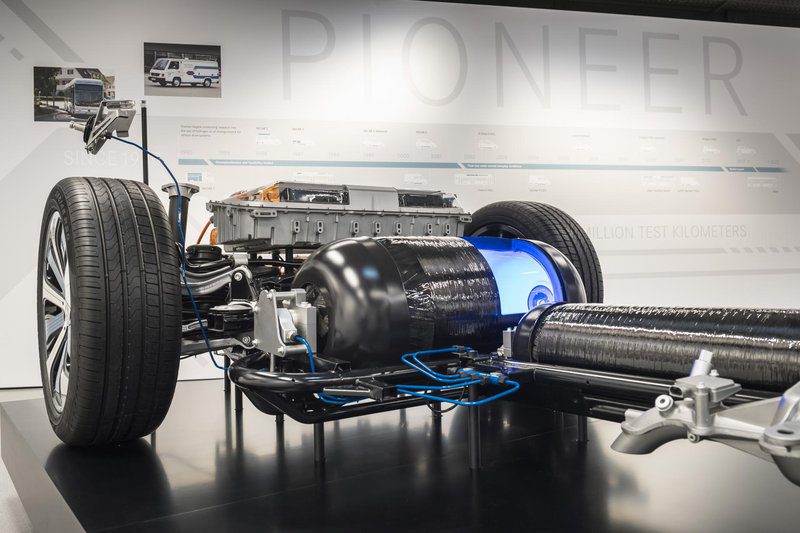

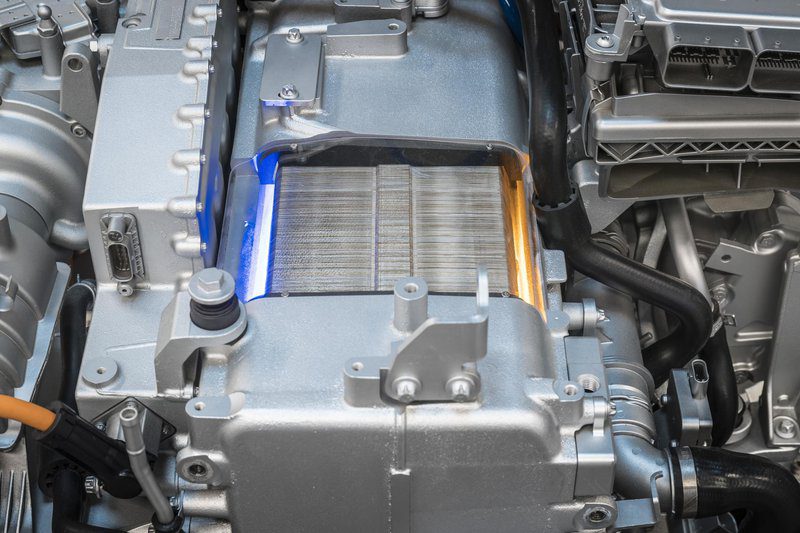

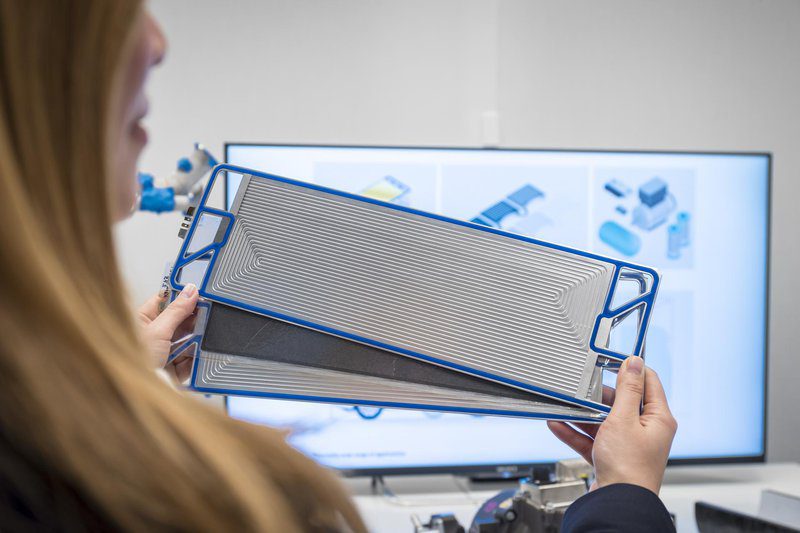

Compared to the previous generation Mercedes fuel cell car (Class B, which has been available in small numbers since 2011), the fuel cell system is 30 percent more compact and can be installed in the normal engine compartment while developing 40 percent more power. ... Fuel cells also have 90 percent less platinum built into them, and they are also 25 percent lighter. With 350 Newton meters of torque and 147 kilowatts of power, the GLC F-Cell prototype responds instantly to the accelerator pedal, as we witnessed as a fellow chief engineer on a 40-kilometer circuit. Stuttgart. Range in H2 mode is 437 kilometers (NEDC in hybrid mode) and 49 kilometers in battery mode (NEDC in battery mode). And thanks to today's conventional 700 bar hydrogen tank technology, the GLC F-Cell can be charged in just three minutes.

The plug-in hybrid fuel cell combines the benefits of both zero-emission driving technologies and optimizes the use of both energy sources to meet current driving requirements. In hybrid mode, the vehicle is powered by both power sources. Peak energy consumption is controlled by the battery, so fuel cells can operate at optimum efficiency. In F-Cell mode, the electricity from the fuel cells constantly keeps the high-voltage battery charged, which means that the electricity from the hydrogen fuel cells is almost exclusively used for driving, and this is an ideal way to conserve battery electricity for certain driving situations. In battery mode, the vehicle is powered entirely by electricity. The electric motor is powered by a battery and the fuel cells are off, which is best for short distances. Finally, there is a charging mode in which charging the high voltage battery takes priority, for example when you want to charge the battery to its maximum total range before discharging hydrogen. In this way, we can also build up a reserve of power before going up or before a very dynamic ride. The GLC F-Cell's drivetrain is very quiet, which is what we expected, and acceleration is instantaneous as soon as you press the accelerator pedal, as is the case with electric vehicles. The chassis is adjusted to prevent too much tilt of the body and works very satisfactorily, also thanks to the ideal weight distribution between the two axles of almost 50-50.

Regarding energy regeneration, the battery charge dropped from 30 to 91 percent when driving uphill after just 51 kilometers, but when driving downhill due to braking and recuperation, it rose again to 67 percent. Otherwise, the drive is possible with three stages of regeneration, which we control using levers next to the steering wheel, very similar to those we are used to in cars with an automatic transmission.

Mercedes-Benz introduced its first fuel cell vehicle back in 1994 (NECA 1), followed by several prototypes, including the Mercedes-Benzon Class A in 2003. In 2011, the company organized a trip around the world. F-Cell World Drive, and in 2015, as part of the F 015 Luxury and Motion study, they introduced a plug-in hybrid fuel cell system for 1.100 kilometers of zero emissions. The same principle now applies to the Mercedes-Benz GLC F-Cell, which is expected to hit the road in limited editions before the end of this year.

The hydrogen tanks manufactured in Mannheim are installed in a safe place between the two axles and are additionally protected by an auxiliary frame. Daimler's Untertürkheim plant produces the entire fuel cell system, and the stock of about 400 fuel cells comes from the Mercedes-Benz Fuell Cell (MBFG) plant in British Columbia, the first plant entirely dedicated to the production and assembly of fuel. stacks of cells. Finally: the lithium-ion battery comes from Daimler's subsidiary Accumotive in Saxony, Germany.

Interview: Jürgen Schenck, Director of the Electric Vehicle Program at Daimler

One of the most challenging technical constraints in the past has been the operation of the system at low temperatures. Can you start this car at 20 degrees Celsius below zero?

Of course you can. We need preheating, some kind of heating, to get the fuel cell system ready. This is why we start driving with a quick start with a battery, which of course is also possible in temperatures below 20 degrees below zero. We cannot use all the available power and we have to stay during the warm-up, but at the beginning there are about 50 "horses" available to drive the car. But on the other hand, we will also offer a plug-in charger and the customer will have the option to pre-heat the fuel cell. In this case, all power will be available initially. Preheating can also be set via the smartphone app.

Does the Mercedes-Benz GLC F-Cell have all-wheel drive? What is the capacity of a lithium-ion battery?

The engine is on the rear axle, so the car is rear-wheel drive. The battery has a net capacity of 9,1 kilowatt hours.

Where will you do it?

In Bremen, in parallel with a car with an internal combustion engine. Production figures will be low as production is limited to the production of fuel cells.

Where will you place the GLC F-Cell at an affordable price?

The price will be comparable to that of a plug-in hybrid diesel model with similar specifications. I can't tell you the exact amount, but it must be reasonable, otherwise no one would have bought it.

Nearly € 70.000, how much is the Toyota Mirai worth?

Our plug-in hybrid diesel vehicle that I mentioned will be available in this area, yes.

What guarantees will you give your clients?

He will have a full guarantee. The car will be available in a full service leasing scheme, which will also include guarantees. I expect it to be about 200.000 km or 10 years, but since it will be a lease it won't be that important.

How much does the car weigh?

It is close to a plug-in hybrid crossover. The fuel cell system is comparable in weight to a four-cylinder engine, the plug-in hybrid system is similar, instead of a nine-speed automatic transmission, we have an electric motor on the rear axle, and instead of a tin tank of gasoline. or diesel – carbon fiber hydrogen tanks. It is slightly heavier overall due to the frame that supports and protects the hydrogen tank.

What do you think are the main characteristics of your fuel cell vehicle compared to what Asians have already introduced to the market?

Obviously, because it is a plug-in hybrid, it solves one of the main problems affecting the reception of fuel cell vehicles. By providing them with a 50-kilometer flight range with just a battery, most of our customers will be able to drive without the need for hydrogen. Then don't worry about the lack of hydrogen charging stations. However, as hydrogen stations become more common on long journeys, the user can easily and quickly fill the tanks completely.

In terms of running costs, what is the difference between using a car with batteries or hydrogen?

Fully battery operation is cheaper. In Germany, it costs about 30 cents per kilowatt-hour, which means about 6 euros per 100 kilometers. With hydrogen, the cost rises to 8-10 euros per 100 kilometers, taking into account the consumption of about one kilogram of hydrogen per 100 kilometers. This means that driving on hydrogen is about 30 percent more expensive.

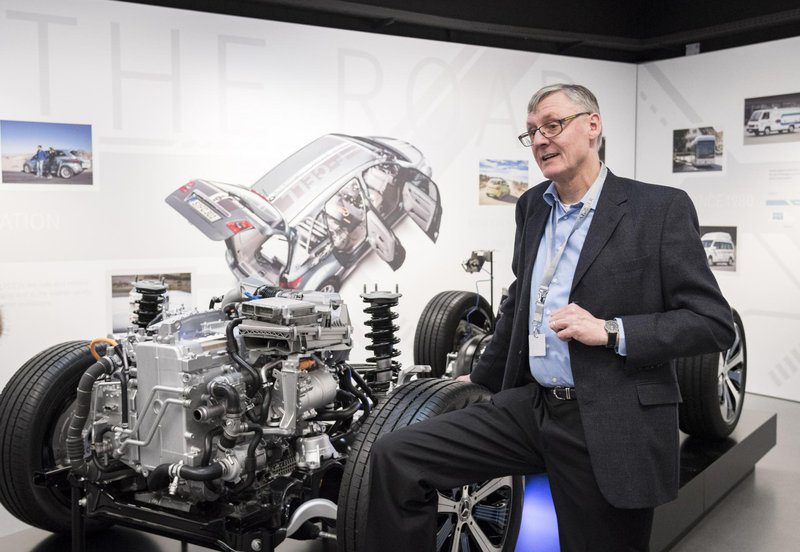

Interview: prof. Dr. Christian Mordic, Daimler Fuel Cell Director

Christian Mordik leads Daimler's Fuel Cell Drives Division and is General Manager of NuCellSys, Daimler's subsidiary for fuel cells and hydrogen storage systems for automobiles. We spoke to him about the future of fuel cell technology and the pre-production GLC F-Cell.

Fuel cell electric vehicles (FCEVs) are seen as the future of propulsion. What prevents this technology from becoming commonplace?

When it comes to the market value of automotive fuel cell systems, no one doubts their performance anymore. Charging infrastructure continues to be the biggest source of customer uncertainty. However, the number of hydrogen pumps is growing everywhere. With the new generation of our vehicle based on the Mercedes-Benz GLC and the integration of connectivity technology, we have achieved an additional increase in range and charging capabilities. Of course, production costs are another aspect, but here too we have made significant progress and clearly see what can be improved.

Currently, hydrogen for fuel cell propulsion continues to be predominantly derived from fossil energy sources such as natural gas. It's not quite green yet, is it?

Actually it is not. But this is only the first step in showing that fuel cell driving without local emissions can be the right alternative. Even with hydrogen derived from natural gas, carbon dioxide emissions across the entire chain could be reduced by a good 25 percent. It is important that we can produce hydrogen on a green basis and that there are indeed many ways to achieve this. Hydrogen is an ideal carrier for storing wind and solar energy, which are not produced continuously. With an ever-increasing share of renewable energy sources, hydrogen will play an increasingly important role in the overall energy system. Consequently, it will become more and more attractive to the mobility sector.

Does your involvement in the development of stationary fuel cell systems play a role here?

Exactly. The potential of hydrogen is wider than only in automobiles, for example, in the service, industrial and household sectors, is obvious and requires the development of new strategies. Economies of scale and modularity are important factors here. Together with our innovative Lab1886 incubator and computer experts, we are currently developing prototype systems for emergency power supply for computer centers and other fixed applications.

What are your next steps?

We need uniform industry standards so that we can move towards large-scale vehicle production. In further developments, the reduction of material costs will be of particular importance. This includes further downsizing of components and the proportion of expensive materials. If we compare the current system with the Mercedes-Benz B-Class F-Cell system, we have already achieved a lot - already by reducing the platinum content by 90 percent. But we must move on. Optimizing manufacturing processes always helps to reduce costs - but it's more a matter of economies of scale. Collaborations, multi-manufacturer projects such as Autostack Industrie, and expected global investment in technology will certainly help this. I believe that by the middle of the next decade and certainly after 2025, the importance of fuel cells in general will increase, and they will be especially important in the transport sector. But it won't come in the form of a sudden explosion, as fuel cells on the world market are likely to continue to occupy only a single digit percentage. But even modest amounts help set standards that are especially important for cost reduction.

Who is the target buyer of a fuel cell vehicle and what role does it play in your company's powertrain portfolio?

Fuel cells are of particular interest to customers who require a long range every day and who are ditching hydrogen pumps. However, for vehicles in urban environments, the battery electric drive is currently a very good solution.

The GLC F-Cell is something special around the world because of its plug-in hybrid drive. Why did you combine fuel cells and battery technology?

We wanted to take advantage of hybridization rather than choose between A or B. The battery has three advantages: we can recover electricity, additional energy is available during acceleration, and the range is increased. The connectivity solution will assist drivers in the early stages of infrastructure development when the hydrogen pump network is still in short supply. For 50 kilometers, you can charge your car at home. And in most cases, that's enough to get to your first hydrogen pump.

Is the fuel cell system more or less complex than a modern diesel engine?

Fuel cells are also complex, perhaps even slightly smaller, but the number of components is about the same.

And if you compare the costs?

If the number of plug-in hybrids and fuel cells produced were the same, they would already be at the same price level today.

So are plug-in hybrid fuel cell vehicles the answer to the future of mobility?

You definitely could be one of them. Batteries and fuel cells form a symbiosis as both technologies complement each other very well. The power and faster response of the batteries support fuel cells that find their ideal operating range in driving situations that require a constant increase in power and greater range. In the future, a combination of flexible batteries and fuel cell modules will be possible, depending on the mobility scenario and vehicle type.