Methods and methods of fuel processing

Content

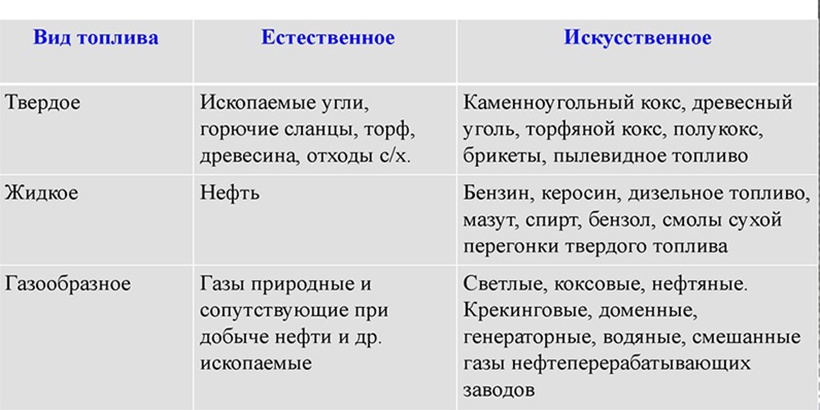

Substances that provide thermal energy when burned and are raw materials for a number of important industries are called fuels. From whether it is obtained as a result of processing, or is in nature in its original form, it is divided into artificial and natural.

To meet the needs of modern chem. industry and other fields of activity, fuel processing is of great importance. The quality of the obtained fuels and lubricants and other materials depends on it. As a result, a person receives the most important hydrocarbon raw materials, which are used in various areas of the national economy. These are diesel fuel (summer and winter), gasoline, kerosene and other valuable products.

Thanks to complex processes, humanity received valuable fuels and lubricants

Fuel processing methods depending on the state of aggregation

For convenience, it is customary to divide all types, both natural and artificial: according to the state of aggregation they are in. It:

- Solid.

- Liquid.

- Gaseous.

Thanks to its simple and cheap transportation via pipelines, gas is increasingly being used as a fuel for space heating and in the industrial sector.

You can choose quality fuels for your needs that will provide maximum efficiency and heat transfer.

International classification

Methods for processing liquid fuels

Oil is the basis of energy, fuel, 80-85% consisting of a complex set of carbons. From 10 to 14% is accounted for by hydrogen, the rest is solid impurities. It is the processing of oil into diesel fuel, gasoline and other combustible substances that is an industry that provides the population with valuable fuels and lubricants.

Before it is processed, it is sent to special separators, where impurities are separated from gases and gasoline. These processes occur by compressing gases with their subsequent cooling. This technique allows you to get gasoline in its liquid form.

There is another way: gas is driven through solar oil, and gasoline is easily distilled off. At the next stage, the gas can already be used, and it is sent to the compressor station. After the gas is removed, oil is purified from water, salt, clay, sand, and other components.

In order for the industry to receive oil refining products - diesel fuel, gasoline and other substances, 2 methods are used:

1.Physical (distillation). This is splitting into fractions (components). This process takes place in 2 stages: engine oil is extracted under pressure. This is how fuel oil is extracted, and then it is processed using vacuum technology and special installations. This method makes it possible to obtain from 10 to 25% of gasoline from raw materials.

Distillation requires special equipment: atmospheric or atmospheric-vacuum installations. They consist of a tube furnace, heat exchangers, pumps, spec. devices. With their help, oil is heated, and, boiling, turns into gas, and, separating, it goes up, and fuel oil flows down.

2.Chemical (pyrolysis, cracking, etc.). Such methods are becoming more and more popular, as they produce better products, and in greater volume. Cracking is a chemical and thermal process of separation of heavy hydrocarbon molecules. As a result, products with a low molecular weight are obtained. This method gives up to 70% of gasoline from raw materials.

Among the derivatives of oil refining, there are three main groups:

- Fuel (boiler, jet and motor).

- Lubricants (technical oils and greases).

- Others (bitumen, paraffin, acids, petroleum jelly, plastic, etc.).

Now the processing of oil into diesel fuel is of great importance for ensuring the normal operation of most enterprises. Diesel fuel is used for railway, road, military transport. Diesel fuel is also an inexpensive product for heating, refueling generators and mini boilers. Today, high-quality diesel fuel is in high demand among the population.

Oil products are of great importance in various areas of the national economy

The main methods of processing solid fuels

Peat, anthracite, lignite and hard coal undergo multiphase processes. Processing of solid fuels is a non-catalytic conversion at extremely high temperatures, where they decompose into a solid residue, gas and liquid. There are 4 methods: destructive hydrogenation, coking, semi-coking and gasification.

Before sending coal for coking, it is sorted, crushed, enriched and dehydrated. The process takes place in coke ovens for 13-14 hours. The gas obtained in this way contains a number of valuable compounds: benzene, ammonia, hydrogen sulfide, etc. During processing, production waste and garbage are burned in the furnace. The result is: resins, gas, coke and semi-coke, slag containing minsol, substitutes for petroleum products, including kerosene, diesel fuel, gasoline, etc.

Transformation of hard rock yields valuable products for industry

High-quality processing of diesel fuel from the best factories

The production of diesel fuel is a complex process that can only be carried out by a large oil refinery in compliance with all stages of the technology. To obtain high-quality diesel fuel, it is necessary to strictly control all stages. Diesel fuel processing consists of three stages:

- Primary processing.

- secondary processing.

- Mixing components.

Various additives are added to improve the quality and consumer properties of diesel fuel.

It is difficult to choose a wide range of fuel on your own. You can ask for help from the managers of LLC TK "AMOKS". This fuel company has been operating on the market for over ten years. Our employee will help you choose the best option for you, calculate the cost of fuel, explain the terms of payment and delivery. We offer high quality products at reasonable prices. Contact us right now, we will be glad to cooperate!

Timely delivery of diesel fuel, gasoline, fuels and lubricants in any volume

Do you have any questions?