Center clutches - the easy way to efficient 4×4 all-wheel drive

The clutch that provides gear shifting is not the only one in the car's transmission. Couplings can also be found in 4x4 drives, where they play a slightly different role.

The clutch that provides gear shifting is not the only one in the car's transmission. Couplings can also be found in 4x4 drives, where they play a slightly different role.

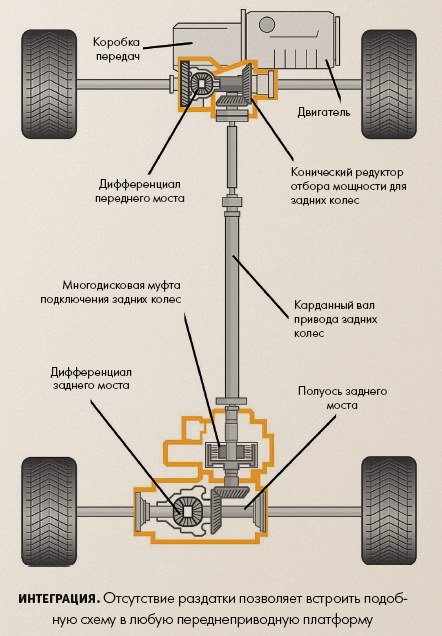

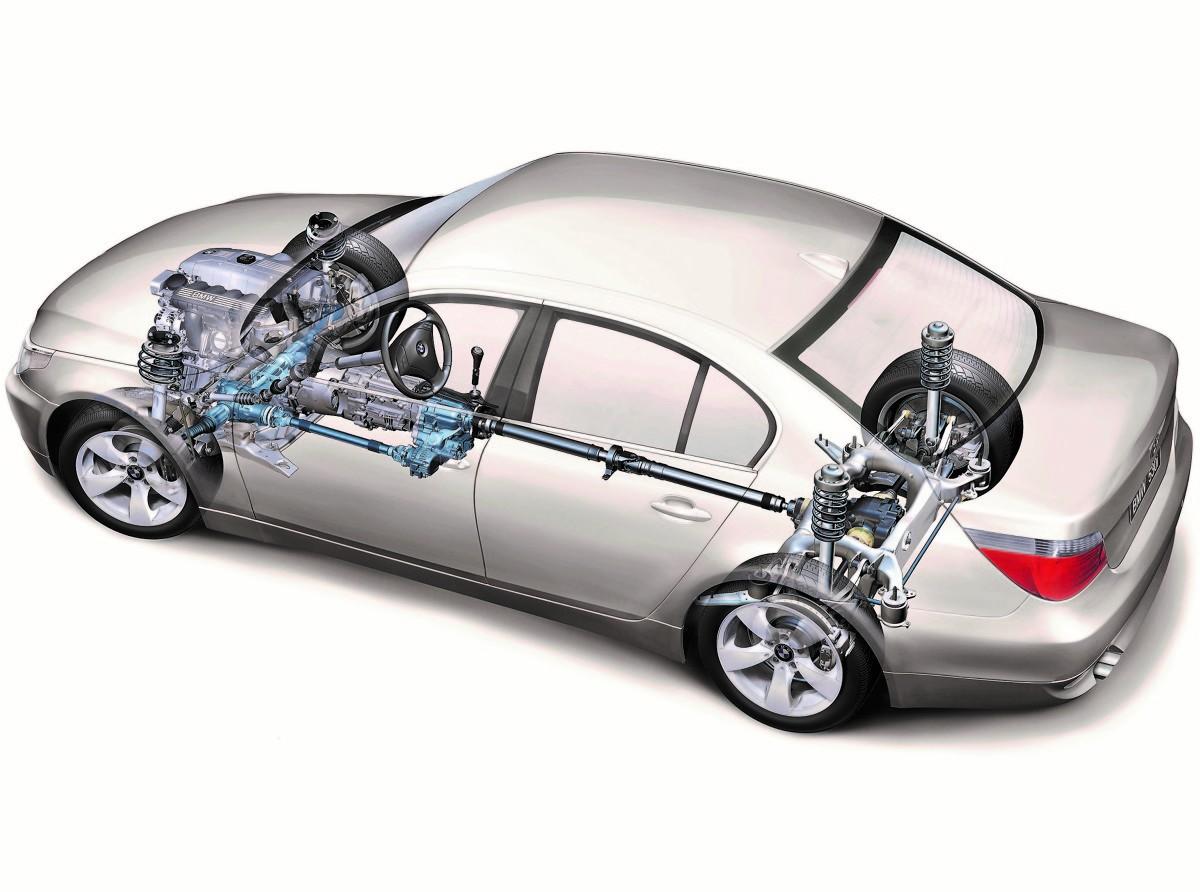

When driving on curves, the wheels of the car overcome different distances and have different speeds of rotation. If each of them rotated independently, the difference in speed would not matter. But the wheels are locked to each other in different ways, and mechanisms are needed to compensate for the difference in speed. One differential with a drive on one axle is used. If we are talking about a 4 × 4 drive, then two differentials are needed (for each axle), and an additional center differential to compensate for the difference in rotation between the axles.

True, some dual-wheel drive vehicles do not have a center differential (such as pickup trucks or simpler SUVs such as the Suzuki Jimny), but this comes with certain limitations. In this case, the four-wheel drive may only be engaged on loose surfaces or roads completely covered with snow or ice. In modern solutions, the center differential is “mandatory”, and in many cases multi-plate clutches fulfill its role. They are popular because in a relatively simple and cheap way they allow you to quickly connect the drive of the second axle (in versions with activation systems) and more or less precisely control the distribution of the drive, depending on the design.

Viscous coupling

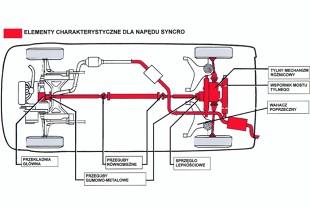

This is the simplest and cheapest type of multi-plate clutch, as it does not have activating and control elements. The clutch discs, which are friction elements, are mounted alternately on the primary and secondary shafts and can slide in the axial direction. One set of disks rotates with the input (drive) shaft, as it is connected to it along the inner circumference through the splines coinciding with the splines of the shaft. A second set of friction discs is installed on the secondary shaft, which in this place has the shape of a large “cup” with slots for the splines of the clutch discs located along their outer circumference. A set of friction discs is enclosed in a housing. This is how each multi-plate clutch is arranged, the differences lie in the clutch actuation and control systems, i.e. in the methods of tightening and releasing the clutch discs. In the case of a viscous coupling, the body is filled with a special silicone oil, which increases its density with increasing temperature. Both shafts, together with the clutch discs mounted on them, as well as the vehicle axles associated with them, can rotate independently of each other. When the car is running under normal conditions, without skidding, both shafts spin at the same speed and nothing happens. The situation is as if the two shafts were in constant relation to each other, and the oil kept the same viscosity all the time.

This is the simplest and cheapest type of multi-plate clutch, as it does not have activating and control elements. The clutch discs, which are friction elements, are mounted alternately on the primary and secondary shafts and can slide in the axial direction. One set of disks rotates with the input (drive) shaft, as it is connected to it along the inner circumference through the splines coinciding with the splines of the shaft. A second set of friction discs is installed on the secondary shaft, which in this place has the shape of a large “cup” with slots for the splines of the clutch discs located along their outer circumference. A set of friction discs is enclosed in a housing. This is how each multi-plate clutch is arranged, the differences lie in the clutch actuation and control systems, i.e. in the methods of tightening and releasing the clutch discs. In the case of a viscous coupling, the body is filled with a special silicone oil, which increases its density with increasing temperature. Both shafts, together with the clutch discs mounted on them, as well as the vehicle axles associated with them, can rotate independently of each other. When the car is running under normal conditions, without skidding, both shafts spin at the same speed and nothing happens. The situation is as if the two shafts were in constant relation to each other, and the oil kept the same viscosity all the time.

The editors recommend:

Pedestrian buttons to disappear from intersections?

This is what you need to know when buying an AC policy

Used roadster at a reasonable price

However, if the cardan shaft, which is driven by the driven axle, starts to rotate faster due to slippage, the temperature in the clutch rises and the oil thickens. The consequence of this is the "sticking" of the clutch discs, the clutch of both axles and the transfer of drive to wheels that are not driving under normal conditions. A viscous clutch does not need an activation system because the clutch discs are automatically engaged. However, this happens with a significant delay, which is the biggest disadvantage of this type of clutch. Another weak point is the transmission of only part of the torque. The oil in the clutch, even when it thickens, still remains liquid and there is always slippage between the discs.

See also: Hyundai i30 in our test

We recommend: New Volvo XC60

hydraulic clutch

An example of a hydraulic multi-plate clutch is the first version of the Haldex clutch, mainly used in Volkswagen and Volvo vehicles. The speed difference between the input and output shafts leads to an increase in oil pressure in the hydraulic part of the clutch. The increase in pressure causes the piston to move, which presses the clutch discs through a special pressure plate. How much torque will be transmitted to the output shaft depends on the oil pressure. The pressure of the clutch discs is controlled by an electronic controller and pressure valves. The control system consists of many elements: clutch sensor, clutch temperature sensor, clutch actuator, engine controller, ABS and ESP system controller, engine speed sensor, wheel speed sensor, gas pedal position sensor, longitudinal acceleration sensor, stop signal ". sensor, secondary brake sensor, additional oil pump and automatic transmission sensor in case of automatic versions.

An example of a hydraulic multi-plate clutch is the first version of the Haldex clutch, mainly used in Volkswagen and Volvo vehicles. The speed difference between the input and output shafts leads to an increase in oil pressure in the hydraulic part of the clutch. The increase in pressure causes the piston to move, which presses the clutch discs through a special pressure plate. How much torque will be transmitted to the output shaft depends on the oil pressure. The pressure of the clutch discs is controlled by an electronic controller and pressure valves. The control system consists of many elements: clutch sensor, clutch temperature sensor, clutch actuator, engine controller, ABS and ESP system controller, engine speed sensor, wheel speed sensor, gas pedal position sensor, longitudinal acceleration sensor, stop signal ". sensor, secondary brake sensor, additional oil pump and automatic transmission sensor in case of automatic versions.

Electro-hydraulic clutch

In this type of clutch, there is no need for a speed difference between the input and output shafts to obtain the oil pressure needed to compress the clutch discs. The pressure is generated by an electric oil pump, which greatly simplifies the entire hydraulic system. The set torque transmitted to the output shaft is realized by the clutch opening degree control valve, which is controlled by the clutch controller. The electric oil pump increases clutch speed as it can build up sufficient oil pressure almost immediately. The control system is based on the same number of elements as in fluid couplings. This design of the center clutch is mainly found in Volkswagen, Ford and Volvo cars.