Motor 1,0 MPI 12V (EA211 – CHYA, CHYB, CPGA)

Content

Minimization reigns in the automotive world, and the trend towards reduced consumption is pushing car manufacturers to develop and subsequently produce engine units that are more environmentally friendly and less economical to manufacture. One of them is also a three-cylinder 1,0 MPI, which is installed in mini cars (VW Up!, Škoda CitiGo, Seat Mii), as well as in Fabia No. 3, where it is the base engine. Thus, the old friend 1,2 HTP is slowly but surely leaving for a more or less well-deserved rest.

In the spirit of minimization, the whole concept of the 1,0 MPI motor unit (EA211) is carried. Compared to 1,2 HTP, it is simpler, lighter and more compact, but at the same time it is not devoid of modern modern technologies. They are used only where they are really needed from a functional point of view. Many unnecessary parts have been completely removed or replaced with a simpler and more reliable option, since the engine must withstand the stress of city traffic, that is, frequent starts and brakes or even several starts per day in winter or summer. During production, great attention was paid to the lowest possible production costs, as well as simple and affordable engine maintenance throughout the entire life of the vehicle.

Key differences between 1,2 HTP and 1,0 MPI

At 1,2 HTP the pistons have a 76,5 bore and relatively long stroke of 86,9 mm, while at 1,0 MPI the pistons have a bore and stroke of just 74,5 x 76,4 mm. In the case of 1,2 HTP, the pistons thus achieve a significantly higher speed, which means significantly higher vibration and vibration amplitudes. Thus, in order to eliminate unwanted vibrations and vibrations, the crankshaft contains large counterweights that are located on each crankshaft trunnion. The balancer shaft also helps to reduce vibrations and vibrations.

At 1,0 MPI, the pistons have a lower speed, so lighter counterweights are used, which are additionally located only on the end pins of the crankshaft. In addition, the mass of the counterweight is located farther from the crankshaft axis of rotation, so that the same inertia is achieved with a lighter crank mechanism. These properties made it possible to abandon the balancing shaft. This represents a significant reduction in frictional losses, which is an important step in the case of a three-cylinder engine to achieve higher mechanical efficiency and therefore lower consumption compared to four-cylinder engines of the same size. Of course, imbalance (first-order vibrations) cannot be completely ruled out from the three-cylinder design principle. The best damping of these vibrations and vibrations is provided by a complex fastening of the engine to the car body.

With these features, the 1,0 MPI engine has significantly better performance, lower noise and easier dialing compared to 1,2 HTP. The new engine has cooling exhaust pipes, so there is no need to protect the catalytic converter by enriching the mixture during more difficult operations (for example, when driving on the motorway). In other words, driving at the permitted 130 no longer means a jump in consumption to values of 9-10 liters, but is about 7 liters. Instead of a timing chain, the timing mechanism drives a flexible toothed belt that better cope with the torsional vibrations of the three-cylinder engine structure.

engine

Simplicity is above all. The engine block itself is made in this spirit. The new 999 cc three-cylinder engine is made from strong, lightweight aluminum alloy to reduce the overall weight of the unit. The engine cylinders are fitted with special gray cast iron inserts and are cast directly into an aluminum block. The manufacturer made sure that the cylinder material was durable and could burn even lower quality fuel. Various vents or oil holes are already molded into the block, eliminating the need for other piping as is common with other engines. The block is cooled by natural water cooling, the so-called Open Deck, in which the upper part of the cylinders is completely open to the flow of coolant, and thus the space around the cylinders is cooled more efficiently. The only partition between this space and the head is the seal under the head.

All cable clamps, various plastics or hoses are placed and attached directly to the engine block, resulting in additional material and weight savings. The bottom of the cylinder block is enclosed by an aluminum alloy crankshaft housing and a simple sheet metal oil pan. The four plain bearings are fitted with a lightweight cast iron crankshaft that, thanks to a redesigned engine, does not require a balance shaft to eliminate vibrations. A well thought-out design with special silent blocks ensures that unwanted vibrations and vibrations from the engine to the body are excluded.

The cylinder head is also made of light alloy, and during its production, care was taken to ensure that the engine warms up to operating temperature as quickly as possible and in the shortest possible time. The designers decided to integrate part of the exhaust pipe directly into the liquid cooling circuit. Thus, in city traffic, the entire unit heats up to operating temperature much faster. This minimizes vapor condensation on the cylinder head cover, fuel condensation on the cylinder walls, and also reduces overall engine wear and fuel consumption.

Divorces

The camshaft cannot be replaced with a new one if damaged or excessively worn. It is pressed into the valve eyelid using a special method. The lid heats up to a high temperature and the core freezes below freezing. The shaft cooled in this way is inserted into the bearing holes of the heated lid. When the temperatures of the materials equalize, a strong and permanent connection is formed at the fulcrum. This creates a very tough yet lightweight construction unit.

Two camshafts drive a total of 12 valves (two intake and two exhaust valves per cylinder), with the advantage that the engine retains the valve tappets. This solution is also more suitable for burning alternative fuels (LPG / CNG). The timing of the intake valves is adjustable so the engine makes better use of the wider speed range. The more powerful 55 kW version of the engine has a speed range of 2000 to 6000 rpm, which increases its maneuverability.

The timing belt is hidden under a plastic cover on the left (now "normal") side of the engine. Interestingly, its dust cover and simple timing design ensures that there is no need to replace the belt throughout the life of the engine. The special Teflon treatment on the inside of the timing belt guarantees a lower frictional resistance.

Injection system and intake manifold

Fuel is injected into the combustion chamber by three injectors at a pressure of only 3 bar. Thus, the overall fuel pump is less stressed. This reduction in injection pressure has a positive effect on the service life of the pump itself. This value was achieved through the use of a 550 mm long intake manifold, consisting of four sections, and high-quality insulation of the manifold and the fuel rail from the heat radiated by the engine itself. The fuel does not overheat, and the "foaming" of the gasoline is minimized, thereby eliminating bubbles in the injection system.

Охлаждение

Cooling of the engine is provided in a completely unusual way. The lightweight aluminum alloy water pump is located on the unconventional right side of the engine (transmission side). The water pump also contains the thermostat module itself, so the number and length of redundant water cooling hoses have been completely kept to a minimum. The water pump is driven by its own belt, thanks to the most compact arrangement of the engine. This entire set (water pump + thermostat) is screwed directly onto the engine block and thus forms a single unit in the cooling circuit.

44 or 55 kW?

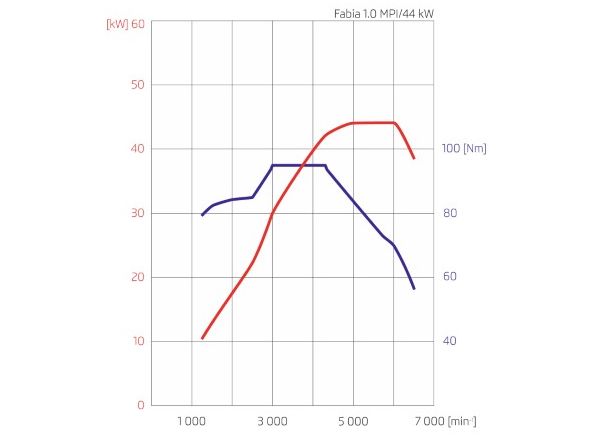

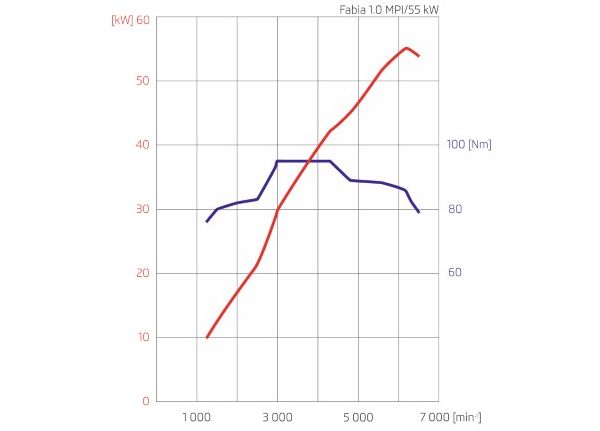

The three-cylinder engine is available in two power ratings: 44 kW (60 PS) at 5500 rpm and 55 kW (75 PS) at 6200 rpm, both of which achieve a maximum torque of 95 Nm in the 3000 range. -4300 rpm. However, in some driving modes, the two versions differ more than the performance suggests at first glance.

In practice, the difference in city traffic between the two versions is minimal, as evidenced by a look at the power and torque graphs of both engines. The minimal difference mentioned is due to the slightly longer accompaniment of the stronger version. A much bigger difference occurs when driving faster. The weaker version spins at 130 km/h at around 3700 rpm, the stronger version at 3900 rpm (applies to the Citigo). At weaker levels above 4000 rpm, a more significant reduction in torque begins and the power curve does not rise significantly. In the case of the stronger version, the power curve rises significantly steeper and announces its spread to 6200 rpm. Similarly, the torque value starts to decrease more significantly.

The above data show that the weaker version is more suitable for driving in the city and the surrounding area, when the speed does not exceed approximately 115 km / h. When this speed is exceeded, the control electronics already intervenes and reduces the dynamics of the engine. When driving this way, the weaker version is also slightly more economical as it contains a longer gear.

On the other hand, the more powerful version is better at handling faster motorway travel and acceleration at higher speeds, either in fifth gear or by downshifting and then turning the engine. Despite the better dynamics, even the more powerful version is not suitable for frequent and extended highway driving, a discipline that is much better suited to larger / more powerful engines with six or more gears.

| engine's type | three-cylinder petrol engine |

| Controller | Bosch ME 17.5.20/XNUMX/XNUMX |

| Number of valves per cylinder | 4 |

| Bias | 999 см |

| Drilling / lifting | 74,5 / 76,4 mm |

| Average piston speed | 15,79 m / s (pri n = 6200 1 / min) |

| Cylinder spacing | 82 mm |

| Transmission of infection | MQ-5F |

| version | MPI 44 kW | MPI 55 kW | EcoFuel 50 kW |

|---|---|---|---|

| Compression ratio | 10,5 | 10,5 | 11,5 |

| Maximum productivity | 44 kW at 5500 rpm | 55 kW at 6200 rpm | 50 kW at 6200 rpm |

| Maximum torque | 95 Nm at 3000-4300 rpm | 95 Nm at 3000-4300 rpm | 90 Nm at 3000-4300 rpm |

| Permanent translation | 3,895 | 4,167 | 4,167 |

| Fuel | BA 95 | BA 95 | CNG/BA 95 |

One comment

gions

The article is nonsense, being translated by google after a foreign material. The 1 mpi engine works on the Atkinson principle. The balancing of the three cylinders is done by the flywheel, the out-of-phase distribution and the auxiliary belt. The exhaust gallery is embedded in the cylinder head. The distribution changes at 160 or 4 years, not as the dog says in the article, that it never changes. and there are other tricks.