Haldex all-wheel drive clutch

Content

Automakers are adding more and more electronic components to the device of a modern car. Such modernization and transmission of the car did not pass by. Electronics allows mechanisms and entire systems to work more accurately and respond much faster to changing operating conditions. A car equipped with four-wheel drive will necessarily have a mechanism responsible for transferring part of the torque to the secondary axle, making it the leading axle.

Depending on the type of vehicle and how engineers solve the problem of connecting all wheels, the transmission can be equipped with a self-locking differential (what is a differential, and what is its principle of operation, is described in a separate review) or a multi-plate clutch, which you can read about separately... In the description of an all-wheel drive model, the concept of a Haldex coupling may be present. It is part of a plug-in all-wheel drive system. One of the analogs of the plug-in all-wheel drive operates due to an automatic differential lock - the development is called Torsen (read about this mechanism here). But this mechanism has a slightly different mode of operation.

Consider what is special about this transmission component, how it works, what kind of malfunctions there are, and also how to choose the right new clutch.

What is Haldex Coupling

As we have already noticed, the Haldex clutch is a component of the drive system with a second axle (front or rear) that can be connected, which makes the machine four-wheel drive. This component ensures smooth connection of the axle when the main drive wheels slip. The amount of torque directly depends on how tightly the clutch is clamped (discs in the structure of the mechanism).

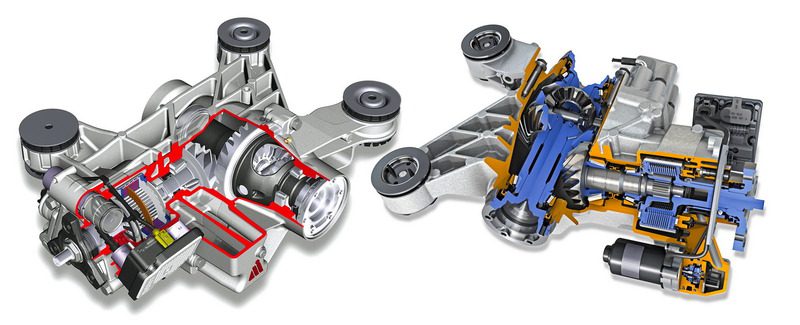

Typically, such a system is installed on a car in which the front-wheel drive is. When a car hits an unstable surface, in this arrangement, the torque is transmitted to the rear wheels. The driver does not need to connect the mechanism by activating any option. The device has an electronic drive and is triggered on the basis of signals sent by the transmission control unit. The very design of the mechanism is installed in the rear axle housing next to the differential.

The peculiarity of this development is that it does not completely disable the rear axle. In fact, rear-wheel drive will work to some extent even if the front wheels have good traction (in which case, the axle still receives up to ten percent of the torque).

This is necessary so that the system is always ready to transfer the required amount of Newtons / meters to the stern of the car. The efficiency of vehicle control and its off-road characteristics depends on how quickly the engagement of all-wheel drive reacts. The speed of the system's reaction can prevent an emergency situation or make driving more comfortable. For example, the beginning of the movement of such a car will be smoother compared to a front-wheel drive relative, and the torque coming from the power unit will be used as efficiently as possible.

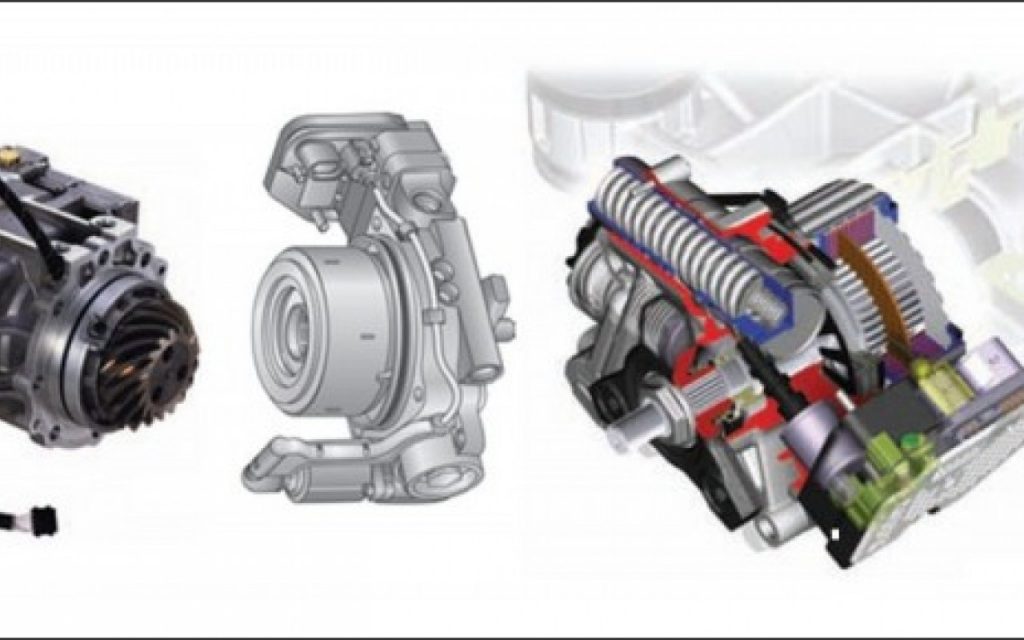

Haldex V coupling appearance

The most efficient system to date is the fifth generation Haldex coupling. The photo below shows how the new device looks like:

Compared to the previous generation, this modification has the same operating principle. The action is performed as follows. When the blocking is activated (this is a conventional concept, since here the differential is not blocked, but the discs are clamped), the disc pack is clamped, and torque is transmitted through it due to the large frictional force. A hydraulic unit is responsible for the operation of the clutch drive, which uses an electric pump.

Before considering the device and what is the peculiarity of the mechanism, let's get acquainted with the history of the creation of this clutch.

Patrimony

Despite the fact that the operation of the Haldex clutch has not changed for more than one decade, during the entire production period this mechanism has gone through four generations. Today there is a fifth modification, which, according to many car owners, is considered the most perfect among analogues. Compared to the previous version, each subsequent generation has become more efficient and technologically advanced. The dimensions of the device became smaller, and the response speed increased.

Designing vehicles with two drive axles, engineers have created two ways to implement interaxle transmission of torque. The first is blocking, and the second is differential. The simplest solution was a lock, with the help of which the second drive axle is rigidly connected at the right time. This is especially true in the case of tractors. This vehicle must work equally well on both hard and soft roads. This is required by the operating conditions - the tractor must move freely on the asphalt road, reaching the desired location, but with the same success it must overcome the difficulties of rough off-road, for example, during plowing a field.

The axles were connected in several ways. It is easier to implement this with a special cam-type or gear-type clutch. To lock the driver, it was necessary to independently move the lock to the appropriate position. Until now, there is a similar transport, since this is one of the simplest types of plug-in drives.

It is much more difficult, but with no less success, to connect the second axis using an automatic mechanism or a viscous clutch. In the first case, the mechanism reacts to the difference in revolutions or torque between the connected nodes and blocks the free rotation of the shafts. The first developments used transfer cases with roller freewheel clutches. When the transport found itself on a hard surface, the mechanism turned off one bridge. When driving on unstable roads, the clutch was locked.

Similar developments were used already in the 1950s in America. In domestic transport, slightly different mechanisms were used. Their device included open ratchet clutches that locked when the drive wheels lost contact with the road surface and slipped. But at extreme loads, such a transmission could seriously suffer, since at the moment of a sharp connection of the all-wheel drive, the second axle was sharply overloaded.

Over time, viscous couplings appeared. Details about their work are described in another article... The novelty, which appeared in the 1980s, turned out to be so effective that with the help of a viscous coupling it was possible to make any car all-wheel drive. The advantages of this development include the softness of connecting the second axle, and for this the driver does not even need to stop the vehicle - the process takes place automatically. But at the same time with this advantage, it is impossible to control the viscous coupling using an ECU. The second significant disadvantage is that the device conflicts with the ABS system (read more about it in another review).

With the advent of the multi-plate friction clutch, engineers were able to bring the process of redistributing torque between the axles to a whole new level. The uniqueness of this mechanism is that the entire process of power take-off distribution can be adjusted depending on the condition of the road, and this can be done using commands from the electronic control unit.

Now wheel slip is not a decisive factor in the operation of systems. The electronics determines the operating mode of the engine, at what speed the gearbox is turned on, records signals from the exchange rate sensors and other systems. All this data is analyzed by a microprocessor, and in accordance with the algorithms programmed at the factory, it is determined with what force the friction element of the mechanism must be squeezed. This will determine in what ratio the torque will be redistributed between the axles. For example, you need to push the car if it starts to get stuck with the front wheels, or vice versa to prevent the stern from working when the car is in a skid.

How does the fifth generation Haldex all-wheel drive (AWD) clutch work?

The latest generation of Haldex all-wheel drive clutch is part of the 4Motion system. Prior to this mechanism, a viscous coupling was used in the system. This element is installed in the machine in the same place where the viscous coupling was installed before it. It is driven by a cardan shaft (for details on what kind of part it is and in what systems it can be used, read here). Power take-off occurs according to the following chain:

- ICE;

- CAT;

- Main gear (front axle);

- Cardan shaft;

- Haldex coupling input shaft.

At this stage, the rigid hitch is interrupted and no torque is delivered to the rear wheels (more precisely, it does, but to a small extent). The output shaft, connected to the rear axle, remains virtually inactive. The drive begins to turn the rear wheels only if the clutch grips the disc pack included in its design.

Conventionally, the operation of the Haldex coupling can be divided into five modes:

- The car starts moving... The clutch friction discs are clamped and the torque is supplied to the rear wheels as well. To do this, the electronics closes the control valve, due to which the oil pressure in the system increases, from which each disc is tightly pressed against the neighboring one. Depending on the power supplied to the drive, as well as the signals coming from different sensors, the control unit determines in what ratio to transfer the torque to the rear of the car. This parameter can vary from a minimum to 100 percent, which in the latter case will make the car rear-wheel drive for a while.

- Slipping of the front wheels at the start of movement... At this point, the aft part of the transmission will receive maximum power, as the front wheels have lost traction. If one wheel slips, then the electronic cross-axle differential lock (or a mechanical analogue, if this system is not in the car) is activated. Only after that the clutch is switched on.

- Constant transport speed... The system control valve opens, oil stops acting on the hydraulic drive, and power is no longer supplied to the rear axle. Depending on the road situation and the function that the driver has activated (in many cars with this system, it is possible to select the driving mode on different types of road surfaces), the electronics redistribute power to a certain extent along the axles by opening / closing the hydraulic control valve.

- Pressing the brake pedal and decelerating the vehicle... At this point, the valve will be open, and all power goes to the front of the transmission due to the fact that the clutches are released.

To upgrade a front-wheel drive car with this system, you will need to carry out a major overhaul of your car. For example, a clutch will not transmit torque without a universal joint. To do this, the car must have a tunnel so that during the ride this part does not cling to the road. It is also necessary to replace the fuel tank with an analogue with a universal joint tunnel. In accordance with this, it will also be necessary to modernize the car's suspension. For these reasons, the installation of all-wheel drive on a front-wheel drive car is carried out at the factory - in a garage environment, this modernization can be performed with high quality, but it will take a lot of time and money.

Here is a small table of how the Haldex clutch works in different driving situations (the availability of some options depends on the car model in which the plug-in four-wheel drive is installed):

| Mode: | Difference in revolutions of the front and rear wheels: | Required power factor for the rear axle: | Clutch operating mode: | Incoming pulses from sensors: |

| Parked car | Petite | Minimum (for preloading or clearing disc gaps) | A lot of pressure is exerted on the disc package, so that they are kept slightly pressed against each other. | Engine speed; Torque; Throttle valve or gas pedal position; Wheel revolutions from each wheel (4 pcs.) |

| The car is accelerating | Much | Much | The oil pressure rises in the line (sometimes to the maximum) | Engine speed; Torque; Throttle valve or gas pedal position; Wheel revolutions from each wheel (4 pcs.) |

| The car is traveling at high speed | Minimum | Minimum | The mechanism is activated depending on the situation on the road and the included transmission mode | Engine speed; Torque; Throttle valve or gas pedal position; Wheel revolutions from each wheel (4 pcs.) |

| The car hit the bumpy road | Variable from small to large | Variable from small to large | The mechanism is clamped, the head in the line reaches its maximum value | Engine speed; Torque; Throttle or gas pedal positions; Wheel revolutions from each wheel (4 pcs.); Additional signals via CAN bus |

| One of the wheels is emergency | Medium to large | Minimum | May be partially inactive or completely inactive | Engine speed; Torque; Throttle valve or gas pedal position; Wheel revolutions from each wheel (4 pcs.); Additional signals via the CAN bus; ABS unit |

| The car slows down | Medium to large | - | Inactive | Wheel speed (4 pcs.); ABS unit; Brake signal switches |

| The car is being towed | High | - | Ignition is inactive, the pump does not work, the clutch does not work | Engine speed below 400 rpm. |

| Diagnostics of the brake system on a roller-type stand | High | - | The ignition is off, the clutch is inactive, the pump does not generate oil pressure | Engine speed below 400 rpm. |

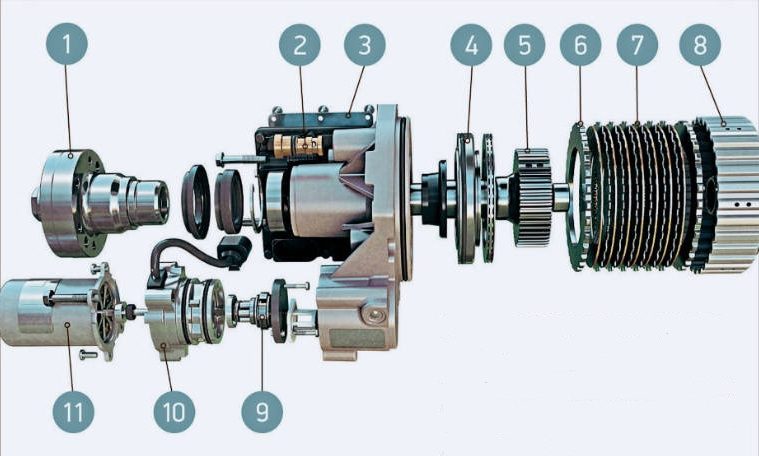

Device and main components

Conventionally, the Haldex coupling design can be divided into three groups:

- Mechanical;

- Hydraulic;

- Electric.

Each of these grooms is made up of different components that perform their own actions. Let's consider each part separately.

Mechanics

The mechanical component consists of:

- Input shaft;

- External and internal drives;

- Hubs;

- Roller supports, in the device of which there are annular pistons;

- Output shaft.

Each part performs a reciprocating or rotary motion.

In the process of operation of the front and rear axles with different shaft speeds, the outer discs, together with the housing, rotate on roller bearings mounted on the output shaft. The support rollers are in contact with the end part of the hub. Since this part of the hub is wavy, the bearings provide the reciprocating movement of the sliding piston.

The shaft exiting the clutch is intended for internal discs. It is fixed to the hub by means of a splined connection, and forms a single structure with the gear. At the entrance to the clutch there is the same design (body with discs and roller bearings), only it is designed for the package of outer discs.

During the operation of the mechanism, the sliding piston moves the oil through the corresponding channels into the cavity of the working piston, which moves from pressure, compressing / expanding the discs. This ensures a mechanical connection between the front and rear axles, if necessary. The line pressure is adjusted by valves.

Гидравлика

The device of the hydraulic unit of the system consists of:

- Pressure valves;

- The reservoir in which the oil is under pressure (depends on the generation of the clutch);

- Oil filter;

- Annular pistons;

- Control valve;

- Restriction valve.

The hydraulic circuit of the system is activated when the speed of the power unit reaches 400 rpm. The oil is pumped to the sliding piston. These elements are simultaneously provided with the necessary lubrication and are also held tightly against the hub.

At the same time, lubricant is pumped under pressure through the pressure valves to the pressure piston. The speed of the clutch is ensured by the fact that the gaps between the spring-loaded discs are eliminated by a small pressure in the system. This parameter is maintained at a level of four bar by a special reservoir (accumulator), but in some modifications this component is absent. Also, this element ensures uniformity of pressure, eliminating pressure surges due to reciprocating piston movements.

The moment oil flows under pressure through the sliding valves and enters the service valve, the clutch is compressed. As a result, the group of discs, fixed on the input shaft, transmits the torque to the second set of discs, fixed on the output shaft. The compression force, as we have already noticed, depends on the pressure of the oil in the line.

While the control valve provides an increase / decrease in the oil pressure, the purpose of the pressure relief valve is to prevent a critical increase in pressure. It is controlled by signals from the transmission ECU. Depending on the situation on the road, which requires its power on the rear axle of the car, the control valve opens slightly to drain the oil into the sump. This makes the clutch work as soft as possible, and its connection is triggered in the shortest possible time, since the entire system is controlled by electronics, and not by mechanisms, as in the case of a mechanically locking differential.

Electronics

The list of electrical components of the clutch consists of many electronic sensors (their number depends on the device of the car and the systems that are installed in it). The Haldex clutch control unit can receive pulses from the following sensors:

- Wheel turns;

- Brake system actuation;

- Hand brake positions;

- Exchange rate stability;

- ABS;

- DPKV crankshaft;

- Oil temperatures;

- Gas pedal positions.

Failure of one of the sensors leads to incorrect redistribution of the four-wheel drive power take-off along the axes. All signals are processed by the control unit, in which specific algorithms are triggered. In some cases, the clutch simply stops responding, since the microprocessor does not receive the required signal to determine the compression force of the clutch.

In the channels of the hydraulic system there is a flow section regulator connected with the control valve. It is a small pin, the position of which is corrected by an electric servo motor, which has a stepping type of operation. His device has a gear wheel connected to a pin. When a signal from the control unit is received, the motor raises / lowers the stem, thereby increasing or decreasing the channel cross-section. This mechanism is needed to prevent the restrictor valve from dumping too much oil into the oil pan.

Haldex couplings generations

Before we look at each generation of the Haldex clutch, it is necessary to recall how the plug-in all-wheel drive differs from the permanent one. In this case, the center differential lock is not used. For this reason, in most situations, power take-off is carried out by the front axle (this is a feature of a system equipped with a Halsex clutch). The rear wheels are connected only if necessary.

The first generation of the clutch appeared in 1998. This was the viscous option. The rear-wheel drive response directly depended on the speed of the front wheel slip. The disadvantage of this modification was that it worked on the basis of the physical properties of liquid materials, which change their density depending on the temperature or the number of revolutions of the driving parts. Because of this, the connection of the second axle occurred abruptly, which could lead to emergencies in standard road conditions. For example, when the car entered a turn, a viscous coupling could work, which was extremely inconvenient for many motorists.

Already that generation received small additions. Some electronic, mechanical, and hydraulic devices have been added to improve the control of the device's actuation:

- ECU;

- Electric pump;

- Electric motor;

- Solenoid valve;

- Stupica;

- Flange;

- Hydraulic blower;

- Friction surface discs;

- Drum.

Blocks the hydraulic pump mechanism - it creates pressure acting on the cylinder, which pressed the discs against each other. To make the hydraulics work faster, an electric motor was put in to help it. The solenoid valve was responsible for relieving excess pressure, due to which the discs were unclenched.

The second generation of the clutch appeared in 2002. There are few differences between the new items and the previous version. The only thing, this clutch was combined with the rear differential. This makes it easier to repair. Instead of a solenoid valve, the manufacturer installed an electro-hydraulic analogue. The device is made simpler with fewer parts. In addition, a more efficient electric pump was used in the design of the clutch, due to which it did not require frequent maintenance (it is able to cope with a large volume of oil).

The third generation of Haldex received similar updates. Nothing cardinal: the system began to work more efficiently due to the installation of a more efficient electric pump and an electro-hydraulic valve. The complete blocking of the mechanism took place within 150ms. This modification is often referred to in the documentation as PREX.

In 2007, the fourth generation of the plug-in all-wheel drive clutch appeared. This time, the manufacturer has radically revised the structure of the mechanism. Due to this, its work has been accelerated, and its reliability has increased. The use of other components has practically eliminated the false alarms of the drive.

The main changes in the system include:

- Lack of rigid blocking based only on the difference in rotation of the front and rear wheels;

- Correction of work is carried out entirely by electronics;

- Instead of a hydraulic pump, an electric analogue with a high performance is installed;

- Full blocking speed has been significantly reduced;

- Thanks to the installation of an electronic transmission control unit, the power take-off redistribution began to be adjusted more accurately and smoothly.

So, the electronics in this modification made it possible to prevent possible slipping of the front wheels, for example, when the driver sharply pressed the accelerator pedal. The clutch was unlocked by signals from the ABS system. The peculiarity of this generation is that it was now intended only for vehicles equipped with the ESP system.

The latest, fifth, generation (produced since 2012) of the Haldex coupling has received updates, thanks to which the manufacturer managed to reduce the dimensions of the device, but at the same time increase its performance. Here are some of the changes that have affected this mechanism:

- In the structure, the oil filter, the valve that controls the circuit closure, and the reservoir for accumulating oil under high pressure were removed;

- The ECU was improved, as well as the electric pump;

- Oil channels appeared in the design, as well as a valve that relieves excess pressure in the system;

- The body of the device itself has been modified.

It is safe to say that the new product is an improved version of the fourth generation of the clutch. It has a long working life and a high degree of reliability. Due to the removal of some parts from the structure, the mechanism became easier to maintain. The maintenance list includes regular gear oil changes (in another article read about how this oil differs from engine lubrication), which must be produced no later than 40 thousand. km. mileage. In addition to this procedure, while changing the lubricant, it is necessary to inspect the pump as well as the internal parts of the mechanism to ensure that there is no wear or contamination.

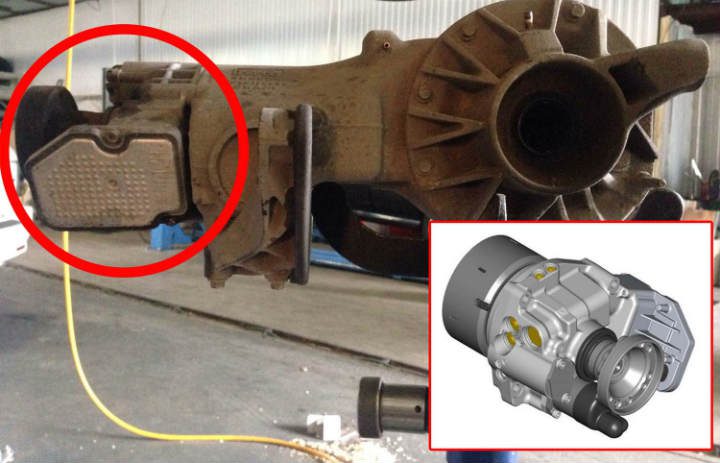

Haldex coupling malfunctions

The Haldex clutch mechanism itself rarely breaks down with timely maintenance. Depending on the car model, this device may fail as a result of:

- Lubricant leaks (sump is punctured or oil leaks on gaskets);

- Untimely oil change. As everyone knows, lubrication in mechanisms not only prevents dry friction of contact parts, but also cools them and washes away metal chips formed by using poor quality parts. As a result, there is a large output on gears and other parts due to the large amount of foreign particles;

- Breakdown of the solenoid or errors in the operation of the control unit;

- ECU breakdowns;

- Failure of the electric pump.

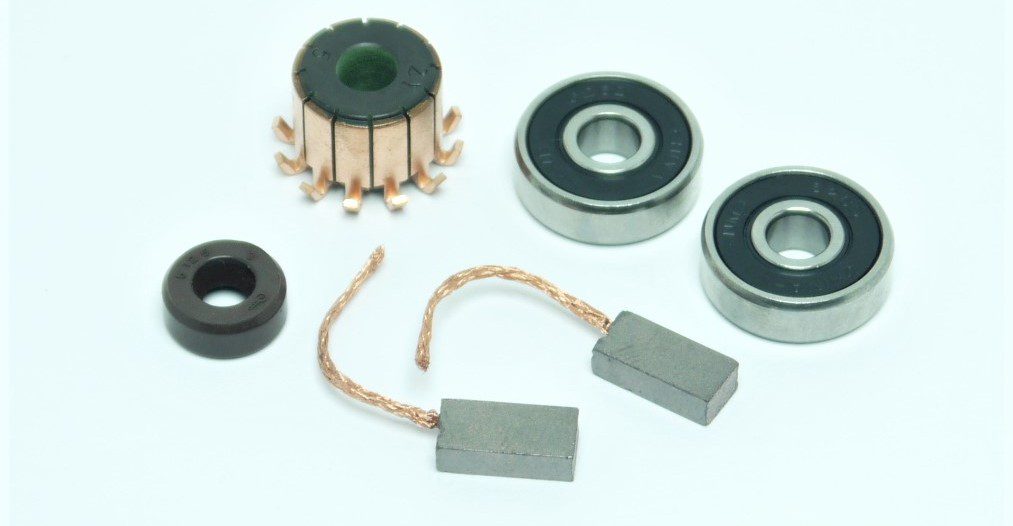

Of these problems, most motorists are faced with the formation of a strong development on parts due to a violation of the oil change schedule. The breakdown of the electric pump is less common. The reasons for its breakdowns may be the wear of the brushes, bearings, or rupture of the winding due to its overheating. The rarest breakdown is a malfunction of the control unit. The only thing that he often suffers from is the oxidation of the case.

Choosing a new Haldex coupling

It is also necessary to adhere to the schedule for routine maintenance of the clutch due to its high cost. For example, a new clutch for some car models produced by the VAG concern will cost more than one thousand dollars (for details on which car models are produced by the VAG concern, read in another article). Given this cost, the manufacturer has provided for the ability to repair the device by replacing some of its components with new ones.

There are several ways to choose an assembled clutch or its individual parts. The easiest one is to remove the mechanism from the car, take it to a car shop and ask the seller to choose an analogue himself.

Despite the difference in the device of generations, it is impossible to make a mistake in the independent selection of the mechanism using the VIN code. Where you can find this number and what information it contains is described separately... You can also find a device or its components by the catalog number, which is indicated on the body of the mechanism or part.

Before selecting a device according to the car data (release date, model and brand), it is necessary to clarify which generation of the coupling was on the car. They are not always interchangeable. This is especially true for spare parts for local repairs. As for the lubricant, a special oil is required for the clutch. In some cases, the breakdown of the electric pump can be eliminated by yourself. For example, if its brushes, oil seals or bearings are worn out.

For the repair of the coupling, repair kits are also offered that can fit different generations of devices. You can check the compatibility of parts by referring to the clutch catalog number or by asking the specialist who will carry out the repair.

Separately, it is worth mentioning the opportunity to buy a refurbished clutch. If you decide to purchase such an option, then you should not do it in the hands of unverified sellers. You can purchase such a device only in proven service stations or at disassembly. Usually, original mechanisms are subjected to a similar procedure, and spare parts of similar quality are used.

Advantages and disadvantages

Positive aspects of the Haldex coupling:

- It responds much faster than a viscous clutch. For example, the viscous coupling is blocked only after the wheels have already started to slip;

- The mechanism is compact;

- Does not conflict with wheel slip prevention systems;

- At the time of the maneuvers, the transmission is not so heavily loaded;

- The mechanism is controlled by electronics, which increases the accuracy and speed of response.

Despite its effectiveness, the Haldex clutch all-wheel drive system has some disadvantages:

- In the first generation of mechanisms, the pressure in the system was created at the wrong time, which is why the response time of the clutch left much to be desired;

- The first two generations suffered from the fact that the clutch is unlocked only after receiving signals from adjacent electronic devices;

- In the fourth generation, there was a disadvantage associated with the lack of an interaxle differential. In this arrangement, it is impossible to transmit all the torque to the rear wheels;

- The fifth generation lacks an oil filter. For this reason, it is necessary to change the lubricant more often;

- Electronics requires careful programming, which makes it impossible to independently upgrade the system.

Hack and predictor Aviator

So, one of the most important components of an all-wheel drive transmission is the unit that distributes the torque between the axles. The Haldex clutch allows a front-wheel drive vehicle to operate in conditions that require off-road performance from the vehicle. The correct distribution of power along the axles is the most important parameter that all developers of various interaxle mechanisms are trying to achieve. And to date, the considered mechanism is the most effective device that provides quick and smooth connection of the rear drive.

Naturally, modern equipment requires more attention and funds for repair, but this device, with timely maintenance, will last a long time.

Additionally, we offer a short video on how the Haldex coupling works:

Questions and answers:

How does the Haldex coupling work? The principle of operation of the clutch boils down to the fact that the mechanism is sensitive to the difference in shaft rotation between the front and rear axles and is blocked when slipping.

What do you need to change the oil in the Haldex coupling? It depends on the transmission generation. The 5th generation has a different oil filter. Basically, the operation is identical for all generations of the mechanism.

What is Haldex in a car? This is a mechanism in a plug-in all-wheel drive. It is triggered when the main axle slips. The clutch is locked and the torque is transmitted to the second axle.

How does the Haldex coupling work? It consists of a pack of friction discs alternating with steel discs. The first ones are fixed on the hub, the second ones - on the clutch drum. The clutch itself is filled with working fluid (under pressure), which presses the discs against each other.

Where is the Haldex coupling? It is mainly used to connect the second axle in cars with a connected all-wheel drive, therefore, it is installed between the front and rear axles (more often in the differential housing in the rear axle).

What is the oil in the Haldex coupling? A special gear lubricant is used for this mechanism. The manufacturer recommends using the original VAG G 055175A2 “Haldex” oil.