Sandpaper granulation - how to choose the right one?

Content

- Types of sandpaper - how to read the markings?

- Gradation of paper is the most important parameter of the material

- How to choose the gradation of paper for the planned work?

- What is an abrasive cloth?

- Wet polishing - what you need to know?

- What abrasive material for leveling the floor?

- Abrasive material for grinding large surfaces.

- What kind of sandpaper for grinding metal?

Sandpaper is the main tool that should be used to effectively remove the outer layer of material (such as wood) or to smooth its surface and prepare for further work. Check what you need to consider in order to choose the right degree of granulation of sandpaper.

If you want to achieve the perfect effect and completely remove the outer coating without damaging the delicate structure of wood, plastic or metal, you need to remember to set the granulation correctly. Then it will be possible to obtain the ideal smoothness of the treated surface and the best visual effect. In the article, you will learn which sandpaper for wood and other raw materials to choose for each job and what to look for before buying.

Types of sandpaper - how to read the markings?

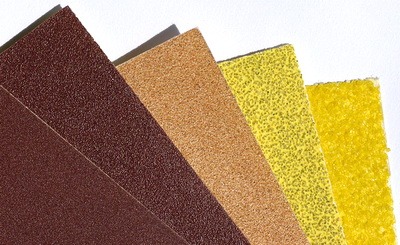

Basically, sandpaper is divided into coarse-grained and fine-grained. However, this general description is not very accurate and is not very helpful at the stage of buying the right paper for the job.

The European Federation of Abrasives (FEPA) sets standards for marking sandpaper, so that its parameters can be clearly defined. These standards are in line with the ISO standard. Grain designations always consist of the letter P followed by a number, such as coarse P50 or fine P1000.

The number next to the P is related to the material passed through the sandpaper sieve. It measures the number of cells per square inch that are in the sieve used to make the grain.

Gradation of paper is the most important parameter of the material

The lower number at the letter P indicates large grains with a strong abrasive effect. The higher the number, the finer grains are suitable for polishing the surface. Fine grains have less abrasive effect. Sandpaper gradation is a key characteristic that determines what the material can be used for.

How to choose the gradation of paper for the planned work?

The gradation of the paper must be adjusted each time according to the type of surface you intend to clean. The rule of thumb is that granulation below P150 is recommended initially. Such material will effectively remove the outer layer of varnish or paint from any type of material. Once the coating has worn off, switch to a paper with a higher grit. It is worth finishing the work by grinding the treated surface with a material with delicate abrasive properties, i.e. paper of the highest quality.

Working with plastic with a delicate surface

When working with abrasion, remember that if you are working with a material that is sensitive to abrasion, and do not want to damage it during processing, you need to quickly switch to a higher grade paper (above P100). The same should be done if the layer of paint or varnish you want to remove is rather thin.

What is the best way to choose the following gradations for processing delicate plastic?

When working with delicate material, it is better to adhere to the so-called doubling rule. It states that there should be a certain distance between different types of sandpaper in terms of gradation. The corresponding space in this case is twice the previous number. In practice, it looks like this: when you start working with P60 paper, after wiping the outer layer, use P120 paper (60x2=120) and then P240 paper (120x2=240). To gradually increase the gradation, you can use a ready-made set of sandpaper, such as Verto sandpaper. In this way, you will effectively protect the machined surface from deep grinding damage.

What is an abrasive cloth?

Due to the fact that it is available in pieces or rolls, the abrasive cloth is very effective and can be used for dry and wet polishing, as well as for sanding the outer layer using hand power and special tools. - shredders. So it's quite versatile. The universal canvas is offered by Vorel.

Wet polishing - what you need to know?

For wet sanding, choose a higher quality paper. Do not forget to soak the paper itself about half an hour before starting work. In this way, you will ensure the appropriate flexibility of the abrasive.

What abrasive material for leveling the floor?

To flatten the base material, such as wood or resin-coated plastic, use P120 or P240 grade paper first. The next step is to apply the epoxy primer. After waiting for the layer to dry and harden, you can start grinding this coating with P400 paper. Finally, a layer of polyurethane paint is applied.

Abrasive material for grinding large surfaces.

Belt sanders are used for processing large surfaces, such as boards. Such sandpaper comes in the form of endless tapes, which greatly speeds up the work. For processing large wooden surfaces, paper with a gradation of about P80 is suitable.

On the other hand, for eccentric sanders, a disc-shaped abrasive that is attached to the sanding surface at the bottom of the device is perfect. Velcro fastening makes it easy to replace a piece of sandpaper after use, and also prevents it from slipping off during work. In this case, the gradation of the abrasive used must be adapted to the number of revolutions of the device. The more revolutions the tool makes during its operation, the lower the gradation of the paper used should be. You can also use dry buffing pads such as Diames.

What kind of sandpaper for grinding metal?

Angle grinders for working with the outer layer of metal require the use of flap discs. Grinding of metal should be done with low-grade paper.

When working with sandpaper, do not forget to select the appropriate paper gradation for the device, the processing method and, above all, the type of surface to be cleaned. Prepare paper with at least three different gradations, and be mindful of their correct gradations. Careful leveling with abrasive material will result in a smooth and absorbent surface, ideally prepared for further work.